New Push Boat Delivered to Plimsoll Marine

Push boat operator Plimsoll Marine announced it has taken delivery of the fourth vessel in a series of newbuilds from Master Marine, Inc. “Plimsoll Marine strives to provide the Lower Mississippi River with premier push boat services utilizing the industry’s most modern and capable fleet of vessels. The delivery of the Steel Skipper marks another milestone in that effort,” said Angus R. Cooper III, President, Cooper/T. Smith. “Our ongoing investment in building and maintaining…

Blakeley BoatWorks Delivers Towboat to Plimsoll Marine

In December 2021 Blakeley BoatWorks completed construction of Green Wave, a fully compliant, state-of-the-art Subchapter M inland push boat. Owned by Plimsoll Marine, the vessel will operate within the Cooper Consolidated fleeting footprint, the largest fleeting footprint on the Lower Mississippi River. All three companies are part of the Cooper Group of Companies.Designed by Farrell and Norton and built by Blakeley BoatWorks over the course of a year, the 70-foot long, 28-foot wide, 1,600 horsepower vessel is fully compliant with the latest U.S.

Marine News' Top Boats of 2021

Sea Change - America’s first hydrogen powered ferrySWITCH Maritime’s new 70-foot passenger ferry Sea Change is navigating uncharted waters as the United States’ first zero-emissions, hydrogen fuel cell-powered, electric-drive ferry.The pioneering aluminum newbuild, constructed by Bellingham, Wash. shipbuilder All American Marine, Inc. (AAM), has been completed and was launched this summer, though permitting of hydrogen fuel systems for maritime vessels is still being worked out with the U.S. Coast Guard.“Legislation and laws for passenger safety did not exist yet for this type of vessel.

Blakeley BoatWorks Delivers Towboat to CMT

The U.S.’ first linehaul towing vessel powered by Tier 4 Caterpillar high-speed engines with selective catalytic reduction( SCR) was built by Blakeley BoatWorks (BBW) and is now operated by Cooper Marine and Timberlands (CMT).In March 2021, Blakeley BoatWorks completed construction of M/V Gretchen V. Cooper, a state-of-the-art, Tier-4 inland linehaul tow boat. This 3,400-horsepower vessel is 110-feet long, 33-feet wide, and expands CMT’s fleet to 20 vessels.Currently, Tier-4 diesel engine standards are the strictest U.S.

Plimsoll Marine Takes Delivery of Pushboat Rock Solid

Bayou La Batre, Ala. shipbuilder Master Marine, Inc. (MMI) has delivered the 67’ x 28’ pushboat Rock Solid to Plimsoll Marine. The Rock Solid is the third of four vessels that MMI is scheduled to deliver to the Lower Mississippi River push boat operator.“The delivery of the Rock Solid marks another milestone in our effort to build and maintain our industry’s most modern and capable fleet of push boats,” said Angus R. Cooper III, President, Cooper/T. Smith. “Our team prides itself…

Master Marine Delivers Towboat to Plimsoll Marine

Master Marine, Inc. (MMI) has delivered the 67- by 28-foot Iron Lady, the first of four new push boats it is building for Lower Mississippi River operator Plimsoll Marine.The four vessels are designed by Entech Designs, LLC. and are fully compliant with all U.S. Coast Guard regulatory requirements.Towboat Iron Lady is powered by two Laborde Products, Inc. Mitsubishi 803 HP Tier III diesel marine engines operating at 1,400 RPM and coupled to Twin Disc 5321 gears. Laborde Products…

North Arm Transport: Innovation in Towing

Founded in 1958 as an extension of the Stradiotti family businesses, North Arm Transportation has grown to be a significant fuel company on the BC coast. Over the years, the company fleet has expanded and evolved. With tugs in a range of size and power, as well as cargo and fuel barges, the company services the coast out of its headquarters in Vancouver on the North Arm of the Fraser River. They also have facilities on Mitchell Island in the Fraser and at Masset on Haida Gwaii.

Taylor Unveils New Barge Material Handling Equipment

Taylor Machine Works, Inc. launched the XHRS-1000, a new model in its material handling equipment portfolio purpose-built to handle containers in the unique lift situations that barge applications present.Hal Nowell, Director of Sales of Taylor Machine Works, said the XHRS is specifically designed for inland rivers and waterway customers.This purpose-built reachstacker is suited to tackle inland waterway barge applications as well as other heavy-duty negative lift applications. The XHR-1000 has a 360-inch wheelbase and features hydraulic stabilizer jacks.

Osage Takes Towboat Delivery from Master Marine

Master Marine, Inc. has delivered a second towboat for Osage Marine Services, Inc. The newly built M/V Frank Mellor, like its sister ship, is a 67’ x 28’ vessel designed by Entech Designs, LLC. All USCG certificates for their Sub M compliance have been obtained.The towboat is powered by a pair of Laborde Products, S6R2-Y3MPTAW Mitsubishi 803 HP Tier III diesel marine engines to be operated at 1,400 RPM coupled to Twin Disc 5321 gears. Laborde Products, Inc. is also providing electrical power with two Northern Lights M65C13.2S 65KW Tier III electronic controlled generators with RW Fernstrum…

Master Marine Delivers M/V Rick Pemberton

Master Marine announced that it has delivered the Entech Designs 67’ x 28’ M/V Rick Pemberton to Waterfront Services.The boat is powered by a pair of Laborde Products, Inc. S6R2-Y3MPTAW Mitsubishi 803 HP tier III diesel marine engines to be operated at 1400 RPM coupled to Twin Disc MG 5321, 5:1 gears, E300 electronic controls with RW Fernstrum, Inc. keel coolers. Laborde Products, Inc. also provided electrical power with (2) Two Northern Lights M65C13.2S 65KW Tier III electronic controlled generators with RW Fernstrum, Inc. keel coolers. A pair of Sound Propeller Services, Inc.

Master Marine Signs Six Towboats

Master Marine, Inc. has signed Six (6) towboats and has laid the keels for the first two vessels. All Six (6) vessels will be 67’ x 28’ Entech Designs, LLC Sub. M compliant towboats. The first two will be working for Osage Marine Services, Inc., St. Louis, MO. with the rest operating in the lower Mississippi River system for an undisclosed customer. We are very happy to be teaming up with these companies to provide them and their customers the latest towboats and equipment available along with meeting Subchapter M requirements. The first two vessels will be delivered and placed into service, by the summer of 2019 with the additional Four (4) vessels to follow in close succession.Each boat will be powered by a pair of Laborde Products…

Master Marine Delivers Towboat to Waterfront Services

Alabama shipbuilder Master Marine has delivered Sam P. Hise, the third towboat in a series of four newbuilds for Illinois-based inland operator Waterfront Services Co.The 67’ x 28’ boat is set up with 10,400 gallons of fuel, 4,359 gallons of potable water and 9,500 gallons of ballast water along with providing a maximum 7’ 9” working draft.Each vessel will be powered by a pair of Laborde Products, Inc. S6R2-Y3MPTAW Mitsubishi 803 HP tier III diesel marine engines to be operated at 1,400 RPM coupled to Twin Disc MG 5321, 5:1 gears, E300 electronic controls with RW Fernstrum, Inc. keel coolers.

Alexis Marine To Retrofit Rivertough to Salt Lugger

Louisiana-based inland workboat operator Alexis Marine has awarded a supply contract to Thordon Bearings for the retrofitting of 6in diameter RiverTough bearings to MV Kristin Alexis, the 60ft twin-screw towboat built by Bollinger Shipyard in 1969.Both the vessel’s shafts will be withdrawn at New Orleans yard Bayou Fabricators and Machine Works, where the original rubber bearings will be replaced with Thordon’s RiverTough tailshaft bearings.The polymer bearing manufacturer will…

New Fleet Boat for Waterfront Services

Alabama shipbuilder Master Marine said it has delivered the newly built M/V Tom Torretti to Waterfront Services Co. The 67’ x 28’ fleet boat is powered by a pair of Laborde Products, Inc. S6R2-Y3MPTAW Mitsubishi 803 HP tier III diesel marine engines to be operated at 1,400 RPM coupled to Twin Disc MG 5321, 5:1 gears, E300 electronic controls with RW Fernstrum, Inc. keel coolers. Electrical power was also provided by Laborde Products, Inc. with two Northern Lights M65C13.2S 65KW Tier III electronic controlled generators with RW Fernstrum, Inc. keel coolers.

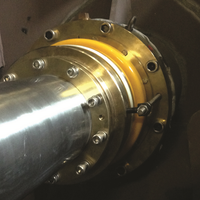

OTI Installs Thordon's Largest TG100 Seal

Offshore Towing Inc (OTI) has completed the refurbishment of its 1974-built 9000hp-class tug Zion Falgout at the Conrad Deepwater shipyard, in Morgan City, La. The milestone project involved the retrofitting of TG100 seals in what marks OTI’s first mechanical shaft seal installation and the largest diameter TG100 series seals ever supplied by Thordon Bearings. An 11.75in (298mm) diameter seal was installed to each propeller shaft of the 66.88t bollard pull twin-screw workhorse.

Master Marine Delivers for Waterfront Services

Master Marine has delivered the first of four 67’ x 28’ fleet boats to Waterfront Services Co. Each boat will be powered by a pair of Laborde Products, Inc. S6R2-Y3MPTAW Mitsubishi 803 HP tier III diesel marine engines to be operated at 1,400 RPM coupled to Twin Disc MG 5321, 5:1 gears, E300 electronic controls with RW Fernstrum, Inc. keel coolers. Electrical power was also provided by Laborde Products, Inc. with two Northern Lights M65C13.2S 65KW Tier III electronic controlled generators with RW Fernstrum, Inc. keel coolers. A pair of Sound Propeller Services, Inc.

VOSTA LMG: 50 Years in Dredge Ball Joints

Celebrating a company milestone this week, VOSTA LMG notes it has been 50 years since the company started with the development and production of bayonet dredge ball joints. The 50 years are a unique amount of experience for the dredge component and it overlaps a significant part of the total history of VOSTA LMG, which goes back to 1873 when the Lübecker Maschinenbau Gesellschaft (LMG) was founded in the German town of Lübeck. The first steps in bayonet dredge ball joints were taken in 1965 in the Dutch village of Spaarndam at Stapel Shipyard…

Pacific Fishermen Shipyard Purchases Union Bay Assets

Pacific Fishermen Shipyard and Electric has purchased selected assets of Union Bay Fabrication, located at Emerald Landing and the former Tippet Shipyard. The purchase included a Cincinnati Model 2512 Plate Shear and 250 ton Mechanical Press Brake Model K5-10. Together they provide capacity to bend and shear heavy steel plates up to 12 feet width and ¾” thickness, dependent on width. The purchase also included weld lead, water and air hose, electrical cords, a welding 4-pack, ventilation fans and miscellaneous shipbuilding equipment.

More Ships Depart Suisun Bay Reserve Fleet

Two obsolete vessels, the Reclaimer and Sagamore, are scheduled to be towed from the Suisun Bay Reserve Fleet on Monday, May 16, 2011. The departures mark the 20th and 21st ships to leave the National Defense Reserve Fleet since October 2009, when the Obama Administration announced its commitment to clean up the site and improve the surrounding environment. As a result, the U.S. Maritime Administration is more than four months ahead of schedule in removing obsolete U.S. ships from the Reserve Fleet. Further, the vessels Bolsterand Clamp are currently scheduled for departure from the Suisun Bay Reserve Fleet on Monday, May 23, 2011. The disposal schedule calls for 20 ships to be removed from SBRF by September 30, 2011.

A Good Hull Deserves a Good Rebuild

British Columbia, on Canada’s west coast, has some attractive and well-proven tugs, but the fleet is aging with many vessels over thirty years old. Four years ago Vancouver’s Island Tug and Barge (www.islandtug.com) launched the new build Island Scout with a pair of Cummins KTA38 main engines. This August, they will return their 1977-built 21 x 7.3-m tug Island Defender to service. The midlife rebuild has taken a year to complete but as Island Tug’s president Bob Shields explained this was much more than a repower…

Connecticut Launches Maritime Cluster

Connecticut Lieutenant Governor M. Jodi Rell recently announced the official launch of the state's newest industry cluster-maritime- at a ceremony on board the Cross Sound Ferry motor vessel, John H., in New London. The organizational center for the cluster, Connecticut Maritime Coalition (CMC) represents the five components of the industry-transportation, manufacturing and services, recreation, commercial fishing environment-working together to help the maritime companies in Connecticut remain competitive in a fierce global market. "The maritime industry has always been a vital part of Connecticut's heritage and today is one of the state's premier economic contributors," Lt. Governor Rell said.

Crowley Takes Delivery of PRT Tug

Crowley Marine Services recently accepted the delivery of Alert - the first of a trio of new 140 ft. 10,192-hp Prevention and Rescue Response Tugs (PRT's) under contract with the Alyeska Pipeline Service Company for use in both Valdez Harbor and Prince William Sound, Alaska. The general purpose PRT's are powered by twin Caterpillar 3612B engines generating the combined 10,192-hp driving two Kamewa Aquamaster azimuthing thrusters. The tugs are also equipped for firefighting, emergency response and oil spill recovery. Recent sea trial proved Alert was able to generate a certified bollard pull of 300,000-lbs., and a free running speed in excess of 16 knots. The entire PRT trio was designed by Guido Perla & Associates, and was constructed at Dakota Creek Shipyard in Anacortes, Wash.

Consent Decree: Companies Responsible for Middle Waterway Cleanup

The U.S. Department of Justice issued a Notice stating that a proposed consent decree with regard to the cleanup of the Middle Waterway Problem Area within the Commencement Bay/Nearshore Tide Flats Superfund Site at Tacoma, Wash. Under the proposed decree, cleanup would be the responsibility of Marine Industries Northwest, Inc.; Foss Maritime Company; Pioneer Industries, Inc.; State of Washington Department of Natural Resources; City of Tacoma; City of Tacoma Department of Public Utilities; Simpson Tacoma Land Company; Simpson Tacoma Kraft Corporation, LLC; Cook's Marine Specialties; Stuart Cook; and Western Machine Works. Comments on the proposed consent decree must be submitted within 30 days. 68 Fed. Reg. 36839