The Headwinds of US Offshore Wind Development

On March 29, 2021, President Biden announced his ambitious plan to deploy 30 gigawatts (GW) of offshore wind power – enough energy to power 10 million U.S. homes – by 2030. The plan would leverage authorities under the Department of Interior, Energy, and Commerce to guide “more than $12 billion per year in capital investment in projects on both U.S. coasts, create tens of thousands of good-paying, union jobs, with more than 44,000 workers employed in offshore wind by 2030 and nearly 33,000 additional jobs in communities supported by offshore wind activity.” The U.S.

Malin Group Acquires Clyde Corrosion

Clyde Corrosion Control Ltd has become part of the Malin Group, with the formal agreement documenting sale of all shares in the company being signed at the Group’s South Rotunda headquarters on October 7. Clyde Corrosion Control will now form a specialist division under the Group’s Malin Newbuild business unit, who specialize in large scale fabrication projects.Founded in 2002 by Bonnie Lowson and rooted in the Clyde’s industrial legacy, Clyde Corrosion Control has an established customer base in Scotland and beyond, spanning the oil and gas, nuclear, construction and renewables sectors.

IMIA Acquires Main Industries

International Marine and Industrial Applicators, LLC (IMIA), a portfolio company of an investment affiliate of J.F. Lehman & Company (JFLCO), announced it has acquired Main Industries, Inc.Headquartered in Hampton, Va., Main Industries provides preservation, scaffolding and environmental containment services to the marine vessel new construction and maintenance, repair, and overhaul (MRO) markets. The company supports the U.S. Navy’s aircraft carrier new construction and MRO requirements (including refueling overhauls) in the Mid-Atlantic region…

By the Numbers: Small Shipyard Grants

Small shipyards in the U.S. are critical to the nation’s maritime operations and economic security. Typically family-owned and employing less than 1,200 workers, America’s small shipyards support more than 400,000 jobs, employ more than 100,000 Americans directly and contribute tens of billions in gross domestic product, according to the U.S. Department of Transportation’s Maritime Administration (MARAD).In an effort to help support these vital assets, MARAD’s Small Shipyard Grant Program provides funds to help drive efficiency…

Blue Atlantic Fabricators Wins Manufacturing Award

Maritime focused steel and aluminum fabrication specialist Blue Atlantic Fabricators said it has been awarded as 2019 Manufacturer of the Year by the Massachusetts Manufacturing Extension Partnership.Formed in August 2014, the Manufacturing Caucus and Annual Manufacturing Awards includes more than 60 legislators from around the state of Massachusetts. Lawmakers focus on training for manufacturing employees; encouraging innovation by helping start-ups access resources; and expanding education and apprenticeship opportunities in key manufacturing centers.

MarAd Grants Fuel U.S. Shipyard Growth

The U.S. Department of Transportation’s Maritime Administration (MARAD) announced $19.6 million in grants to support capital improvements at 28 U.S. small shipyards as a part of its Small Shipyard Grant program. The grants enable small shipyards to modernize equipment and processes to fuel future growth. “These grants help create jobs in America’s small shipyards, which play a significant role in our country’s maritime sector,” said U.S. Transportation Secretary Elaine L. Chao.In 2013, U.S. shipbuilders produced $37.3 billion in gross domestic product.

Blue Atlantic Fabricators Launches Lovejoy Wharf Ferry & Water Taxi Dock

Boston Harbor Cruises’ new subsidiary is building for Massachusetts in the Commonwealth.Blue Atlantic Fabricators of East Boston, MA announces the fabrication and launch of a 50 ton, 20ft x 80ft floating dock to be located at Lovejoy Wharf in Boston. This all-steel dock, will be the facility for privately-run ferry and water taxi service between Lovejoy Wharf and Boston’s Seaport District, offering both bow-loading and side loading capabilities.Blue Atlantic Fabricators built the floating dock for C. White Marine, Inc. who, as general marine contractor for developer Related Beal, will finish and install the docking system at the multiuse Lovejoy Wharf property.

Drydocks World Completes FPSO Upgrade, Turret Mooring Project

Drydocks World has recently completed two projects for Bluewater Energy Services B.V. and end client Hurricane Energy plc.The projects included the refurbishment, life extension and upgrade of the FPSO Aoka Mizu vessel, and the construction of a Turret Buoy weighing over 1,000T. In addition to the complex buoy construction project, Drydocks World teams fabricated and installed over 1,000T of structural steel, 1,800 pipe spools (including Duplex), and 55km of cables on the FPSO.The FPSO Aoka Mizu will be deployed on the Lancaster field…

Ship Repair: May Ship Repair Diversifies

The shipbuilding and repair market has been slightly increasing over the past year with most of the increase being sporadic on vessel repair. New construction has been steady and in May Ship Repairs business, we have been focused on infrastructure expansion such as passenger ferry landings for the City of New York. Looking to the future, May Ship anticipates this trend to continue or even decline due to possible trade tariffs and lack of needed new construction of small to midsized…

Hempel Invests in Fire Protection Coatings R&D

Coatings manufacturer Hempel announced that it is investing in a new research and development center focused solely on passive fire protection coatings. Located just outside Barcelona in Spain, the center is due to open toward the end of 2018. Passive fire protection (PFP) coatings are increasingly important in the construction and oil and gas industries. Applied to structural steel in large buildings and industrial oil and gas installations, the coatings expand to form an insulating layer of carbon char when exposed to high temperatures.

Earth, Wind & … Fire Protection

Three years ago coatings giant Jotun was buying up real estate for U.S. market access and location savings. The effort to get closer to its shipping and offshore customer base is still underway with research aimed at protecting client assets in frontier areas like the arctic. An R&D expansion at Flixborough in the U.K. and in the Arctic archipelago of Spitsbergen aims to make active the fire response of passive surface treatments. There’s a need to address fires in enclosed steel workplaces plus high-temperature hydrocarbon fires.

FDR’s Yacht Plies the Waters of San Francisco Bay

President Franklin D. Roosevelt’s presidential yacht, Potomac, is once again plying the waters of San Francisco Bay after undergoing a maintenance drydocking at Bay Ship and Yacht in Alameda, Calif. Long known as the “Floating White House,” she served as the presidential yacht until his death in 1945. She has a storied past from her start as a Presidential yacht to the King’s yacht (Elvis Presley) and several other lives in-between. Now under management of the Potomac Association, she is under constant care and refurbishment to combat the elements of time.

PPG Debuts New Coatings for Steel, Metal Applications

PPG has introduced PSX 800 and PSX 805 coatings for steel and metal surfaces, two next-generation products formulated with greater flexibility and hiding performance than competing polysiloxane coatings. According to PPG, the two new products feature improved flexibility, which enables them to withstand the cracking under stress commonly associated with difficult steel, tank exterior and building exterior applications. PSX 805 coating adds a durable satin-sheen finish that masks imperfections on metal surfaces.

mltech Bags Caspian Contract

mltech, specialist in pipework set-up and measurement software development, has increased its global presence after securing its first contract in Baku, Azerbaijan. The one year contract, which has scope for extension, was awarded by Metal Qaynaq Sinaq (MQS) which operates throughout Azerbaijan, Georgia and Kazakhstan. The company provides services including process piping fabrication, heavy and light structural steel fabrication, mechanical site services and civil construction to some of the oil and gas industry’s biggest operators and tier one contractors. The project will see mltech train MQS personnel to use its proprietary automet™ software, licensed to MQS, to perform pipe spool fabrication surveys and on-site pipework and steelwork surveys.

Burgess Marine wins Stamp of Approval for CE Marking

Britain’s largest independent ship repairer and marine engineering services provider Burgess Marine has improved its service offering by obtaining third party accreditation to CE Mark structural steel and aluminium fabrications, and by signing a framework agreement with design firm Houlder. CE Marking has become mandatory for all construction products where the product is covered by a harmonised European standard (hEN). BS EN 1090 is one such harmonised standard which covers structural steel and aluminium fabrication. Since July 2014, products within the scope of this standard must be CE Marked. Companies producing structural steel or aluminium fabrications which are being sold in the UK or the wider European Economic Area are legally required to CE Mark the product.

Abu Dhabi Ship Building Commissions First Floating Dock

Abu Dhabi Ship Building PJSC (ADSB) has commissioned its first floating drydock located in Mina Zayed as the company looks to expand its commercial service offering. “The addition of the floating drydock contributes to our commitment to expand our service offering, strengthening our local maritime services and industries, and delivering on the large scale goal of Abu Dhabi’s continued economic diversification,” said ADSB’s CEO Dr. Khaled Al Mazrouei. According to ADSB, the new floating drydock enhances its service capabilities…

Twin Dredgers for Canadian Oil Sands

Damen Shipyards Group has completed a construction contract comprising two electric-powered Cutter Suction Dredgers (CSD) for the Canadian oil sands industry. With both vessels built in Canada, the contract marks the close cooperation between Damen and Aecon, Canada’s largest publicly traded infrastructure development and construction company. Two newly-built Damen CSDs have commenced operations in Northern Alberta, Canada. The two 40.64-meter-long vessels perform dredging duties in oil sands tailings ponds.

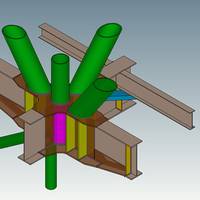

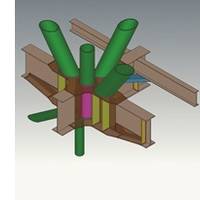

Kværner Verdal AS Selects AVEVA Bocad

Press release - Kværner Verdal AS has selected AVEVA Bocad Steel and AVEVA Bocad Offshore for use at its design and fabrication yard in Verdal, Norway. Kværner required a specialized structural steel design solution that provided out-of-the box functionality and powerful integration. Through the use of AVEVA Bocad Offshore, Kværner benefits from software that is specifically created for the design, detailing and fabrication of all forms of offshore steel structures. When integrated with Kværner’s AVEVA PDMS deployment…

LGH Expands Equipment Rental Fleet

Lifting Gear Hire (LGH), a company providing lifting and moving equipment for rent and sale, announced the addition of several new products to its equipment rental fleet. Joining the company’s rental portfolio is a 4x4x2 Gated Material Basket, as well as several new rigging rollers, including include Beam Clamp Rigging Rollers, Beam Clamp Multi-Rollers and Rack Rollers – each piece of equipment tested, inspected and certified upon request, and all available for immediate rental.

AVEVA Upgrades Structural Steel Software

AVEVA has released new enhancements to its AVEVA Bocad product range for structural steel detailing software. AVEVA Bocad features a plate and bar nesting capability for more efficient planning and use of materials, the developer said. An enhanced weld numbering and traceability feature provides efficient increased fabrication efficiency, design quality assurance and improved structural integrity maintenance. In addition, elements of AVEVA Bocad can now be brought into AVEVA Marine production tools to fabricate detailed ship and offshore designs.

Next Generation of RAmparts Tugs for SAAM

Chilean maritime services and logistics company SAAM S.A. has signed a contract with naval architecture firm Robert Allan Ltd. for a new generation of RAmparts 2400-W Class tugs. The first two boats for SAAM’s Peruvian affiliate TRAMARSA, named Chincha and Tupac, are now under construction at Wuxi Shipyard in China with others soon to follow. The RAmparts 2400-W Class tugboat is a twin Z-drive, diesel-powered tug, designed for ship-assist and terminal support operations. Ship-handling is performed over the bow using a split drum hawser winch.

Hard Problems Demand Soft(ware) Solutions

Make no mistake, the commercial maritime industry will always revolve around heavy duty machinery and mega-machines designed to weather some of the toughest operating conditions on earth. But in recent years a proliferation of Software Solutions has evolved to help the machines operate more efficiently and cost effectively. MR editors report on latest developments in maritime specific Software Solutions. Kværner Verdal AS selected AVEVA Bocad Steel and AVEVA Bocad Offshore for use at its design and fabrication yard in Verdal…

ESAB Weldcloud for Higher Productivity

Secure, robust, flexible, scalable and future-proof, the new ESAB WeldCloud online data management platform works with ESAB’s Aristo Mig semi-automatic, Aristo Mig 5000iR robotic and LAF/TAF sub arc welding systems. Users can purchase these systems WeldCloud-ready, and ESAB can retrofit most existing systems with a communication module. Much more than data recording systems, Weld Cloud integrates with other customer systems (ERP, MDM, MRP, QA, etc.) and enables a wealth of analytics. Using any device with a web browser, users access applications and dashboards with functionality tailored for the job needs of different personnel: operations managers, quality managers, engineers, welders, maintenance staff, training supervisors and others.