Congo’s First LNG Cargo to Set Sail in Coming Days

The first LNG cargo from Eni's Congo LNG project is currently being loaded and will sail to Piombino’s regasification terminal in Italy in the coming days.With the first cargo, the Republic of the Congo enters the group of LNG exporting countries, opening up opportunities for economic growth while contributing to global energy balance.The Congo LNG project, sanctioned in December 2022, came on stream after just one year, in line with the initial timeline.Eni started the introduction…

BP Welcomes FLNG Gimi in West Africa

The floating liquefied natural gas (FLNG) vessel Gimi, that is a core component of the Greater Tortue Ahmeyim (GTA) LNG project, has arrived at its destination on the Mauritania and Senegal maritime border.The FLNG vessel Gimi is at the heart of the GTA Phase 1 development, operated by BP with partners, Kosmos Energy, PETROSEN and SMH.GTA Phase 1 is set to produce around 2.3 million tonnes of LNG per year. The innovative project is expected to produce LNG for more than 20 years…

New Fortress Energy Gets US Clearance to Ship Altamira LNG

U.S. Customs and Border Protection has issued a ruling to New Fortress Energy, confirming that the transportation of LNG produced at the its FLNG facility located offshore Altamira in Mexico by non-U.S. qualified vessels would not violate the Jones Act.As a result of this ruling, NFE is now able to sell and deliver LNG produced at its FLNG facility located offshore Altamira, Mexico to U.S. locations, including Puerto Rico.Puerto Rico represents a key downstream market for New Fortress Energy…

Samsung Heavy Industries Gets $1.5B FLNG Order

Samsung Heavy Industries (SHI) has secured an engineering, procurement and construction (EPC) contract for a new floating LNG production unit worth $1.5 billion.SHI formed a consortium with Black & Veatch for the delivery of the new FLNG unit, subject to final investment decision for the project (FID) being developed by the 'North American client'.Undisclosed by SHI, the client is most likely Haisla Nation and Pembina Pipeline Corporation (Pembina), a partner in the development of the proposed Cedar LNG project…

Exmar Announces Leadership Change

Carl-Antoine Saverys has been named CEO of listed Belgian shipowner Exmar, the company announced Tuesday. Effective January 1, 2024, he will take over from Francis Mottrie who will stay on board as COO.After assuming various roles in the shipping industry, Carl-Antoine Saverys has held deputy roles within Exmar over the past six years, including the company’s infrastructure department and thereafter at the shipping department.Joining him at the executive top level are newly appointed CFO…

Shell's Prelude LNG Facility Expected to Resume Exports Next Month

Shell has almost finished extensive maintenance at its Prelude floating liquefied natural gas (FLNG) facility off Australia and is set to resume exports next month, according to industry sources and shipping data.The timing of the giant floating facility's return to operations is likely to coincide with peak consumption in major markets, including China and Europe, as winter in the northern hemisphere drives demand, although high inventories have limited buying so far this year.In a sign that the work…

FLNG Gimi Delivered and Sailing to Africa

Golar LNG has announced that the FLNG Gimi has departed Singapore’s Seatrium Shipyard and is now sailing under its own propulsion, supported by an escort tug, toward BP’s purpose-built Greater Tortue Ahmeyim (GTA) hub offshore Mauritania and Senegal.The voyage is expected to take around 60 days, including refuelling stops in Mauritius prior to rounding the Cape of Good Hope and in Namibia prior to its arrival. The FLNG will then be moored and connected to the hub, which is expected…

ABS Grants Approval for Bumi Armada FLNG Design

The American Bureau of Shipping has awarded an approval in principle (AIP) to Malaysian floating production firm Bumi Armada for a floating liquefied natural gas (FLNG) infrastructure design. The new concept incorporates a barge-based liquefaction unit and utilizes existing LNG carriers for storage. ABS completed design reviews based on class and statutory requirements."We are pleased to support Bumi Armada in their ongoing efforts to offer safe and reliable LNG storage solutions.

Tango FLNG and Excalibur FSU Set to Begin Journey from Dubai to Eni's Congo LNG Project

The sailaway ceremony for the Tango floating liquefied natural gas (FLNG) unit and Excalibur floating storage unit (FSU) was held Saturday to mark the vessels' sail away from Dubai to Congo, where they will serve Eni's Congo LNG project, whose first phase will start in December 2023.Tango FLNG, which has a liquefaction capacity of approximately 1 billion cubic meters per annum of gas (BCMA), will be moored 3 kilometers offshore along with the Excalibur FSU upon their arrival to Congo.EXMAR is serving as the engineering, procurement and conversion (EPC) contractor for this project, and has desi

Shell's Australian FLNG Facility Poised for Mid-November Restart

Shell is expected to complete maintenance at its flagship Prelude liquefied natural gas (LNG) facility off Australia by mid-November, two sources close to the project told Reuters on Wednesday.The British energy giant started maintenance work at the 3.6-million metric ton a year floating LNG plant in August. A top Shell executive then said in September it was a "major turnaround" work that would last roughly two months.The maintenance is now expected to be completed by mid-November, slightly longer than initially planned after several new issues were discovered and fixed, one of the sources said."The first LNG delivery cargo is now expected by mid-November," the second source said.The last cargo to have left the facility was on Aug.

FLNG Unit for BP's Tortue Ahmeyim Project Nearing Completion

The Golar Gimi FLNG unit, being built for BP's Tortue Ahmeyim project in Senegal/Mauritania offshore area, is set to sail away next month.According to Golar LNG, tasked with delivering the unit, the FLNG Gimi conversion works 97% complete. Golar LNG said that FLNG Gimi was scheduled to leave the yard in September 2023. „Final checks, storing up and sea trials will then take place in Singapore ahead of her voyage to Mauritania and Senegal, expected to commence around the end of September/early October…

Engie, Svanehøj Team Up to Make LNG Storage on FSRUs Safer

Svanehøj and energy researchers at Engie Lab Crigen have joined forces to develop more effective safety measures regarding LNG storage on FSRU.According to Svanehøj , stratifications and roll-overs pose significant safety risks when natural gas is liquified and stored in a cryogenic state. "Recognizing the crucial importance of roll-over prediction software for LNG storage on FSRUs, Svanehøj and Engie Lab Crigen have joined hands to address this critical concern. Limited knowledge…

Wison’s FLNG FEED Design Earns AIP from ABS

Classification society ABS announced it has granted approval In principle (AIP) to Wison Offshore and Marine’s (WOM) Extended FEED on its standardized 3.5 MTPA floating liquefied natural gas (FLNG) design.WOM has said the standardized design reduces CO2 emissions and results in a shortened engineering schedule by about 40%.Jiang Hao, WOM General Manager, FLNG Division, said, “WOM continues to optimize and standardize FLNG design, which would significantly improve the production efficiency and effectively reduce the carbon emissions in the production process. . .

Samsung Heavy Industries Taps GTT for Tank Design of New FLNG Unit

French engineering firm GTT said Tuesday it had received an order from its South Korea-based shipbuilder Samsung Heavy Industries for the tank design of a new Floating Liquefied Natural Gas (FLNG) unit. According to GTT, Samsung is building the FLNG for "an Asian company.""With a total storage capacity of 200,000 m3, this FLNG will be the first fitted with the membrane containment system Mark III Flex developed by GTT. Its delivery is scheduled for the first quarter of 2027," GTT said.Philippe Berterottière…

Lukoil-backed Congo Project to Start Producing LNG in December

A senior executive at Russia's Lukoil energy company said a project in the Congo in which it is involved would begin producing liquefied natural gas (LNG) in December, Russian news agencies reported. Lukoil Vice President Ivan Romanovsky said the initiative would produce around 600,000 tonnes of LNG per year, and that Lukoil plans to boost total LNG output at the Marine XII oil and gas project in the Congo to 3 million tonnes by the end of 2025.Lukoil acquired a 25% stake in Marine XII in 2019.

Golar LNG Buys NFE's Stake in FLNG Hilli

Golar LNG has acquired New Fortress Energy's (NFE) stake in FLNG Hilli - also known as Hilli Episeyo. "In return for NFE’s 50% Common Unit holding in Golar Hilli LLC, Golar has transferred its remaining 4.1 million NFE shares to NFE, paid NFE $100 million in cash, and assumed approximately $323 million of FLNG Hilli debt," Golar LNG said. FLNG Hilli (Hilli Episeyo) is currently located offshore Kribi, Cameroon. Its customers are oil and gas company Perenco and Cameroon’s national oil firm, Société Nationale des Hydrocarbures (SNH).

S5 Inks Deal with Deutsche ReGas to Manage Shuttle Tankers

S5 Agency World (S5) signed a contract with Deutsche ReGas to act as terminal agent at its new Deutsche Ostsee LNG terminal at Lubmin Port, on Germany’s Baltic Sea coast. The new LNG terminal will process LNG imports into Germany and has a regasification apacity of up to 5.2 bcm of natural gas per year. The agreement will see S5 Agency World managed the incoming clearance, pilot coordination and necessary paperwork for three shuttle tankers working between a floating storage unit moored near the port in the Baltic Sea and the floating regasification vessel Neptune at the Lubmin terminal.

Prelude Loads First Tanker Since Output Suspension

The first liquefied natural gas (LNG) tanker to berth at Shell's Prelude floating LNG site off Western Australia since it was shut down after a fire has begun loading, Refinitiv data shows.The Methane Becki Anne vessel berthed at the Prelude plant on Jan. 17, Refinitiv ship-tracking data showed.Gas production at the 3.6 million tonne Prelude facility had been suspended in mid-December after a small fire. At the time, Shell gave no timeline for when the plant would resume output…

Eni to Deploy FLNG Unit Offshore the Republic of Congo

Italian oil giant Eni has signed a contract with China's Wison Heavy Industry for the construction and installation of a floating liquefied natural gas (FLNG) unit with a capacity of 2.4 MTPA (million tons per annum). The FLNG will be deployed offshore the Republic of Congo.The 380-meter-long and 60-meter-wide vessel will be anchored at a water-depth of around 40 meters and will be able to store over 180,000 cubic meters of LNG and 45,000 cubic meters of LPG. Preliminary activities have already started…

Report: Output from Shell's Prelude FLNG Shut Again

Shell has stopped production at its Prelude floating LNG plant off Western Australia after a fire.A Shell spokesperson told Reuters on Thursday that the fire at the giant FLNG unit "was rapidly extinguished."The 488-meter-long, Shell-operated, Prelude FLNG unit forms part of an offshore development that produces natural gas from the remote namesake field, located approximately 475 km north-northeast of Broome in Western Australia. The Prelude is the world's largest FLNG unit.The first LNG shipment from the project - originally sanctioned in 2011 - was shipped back in June 2019, via the Valencia Knutsen LNG tanker to customers in Asia.

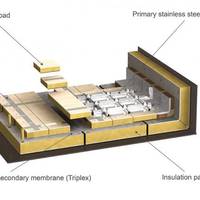

N'GENIUS Says Its Steel to Transform Construction of Offshore, LNG Facilities

N'GENIUS claims its high-strength austenitic stainless steels will transform the design and construction of onshore and offshore oil, gas, and LNG facilities."The global demand for LNG is projected to reach 700 million tonnes per year by 2040 fuelling the need for greater LNG infrastructure including import receiving and export terminals, FLNG vessels, and LNG carriers. Since these facilities are being designed with larger capacities and operating under increasingly more challenging conditions…

VTTI Plans New 5 bcm Floating LNG Platform in Netherlands by 2024

Dutch energy company VTTI said on Monday it plans to build a new floating liquefied natural gas (LNG) terminal in the Netherlands with capacity to import 5 billion cubic meters of gas annually. On Friday the Dutch government said it was in talks with two different groups over new LNG terminals to increase Dutch import capacity by 5-8 billion cubic meters (bcm) annually as it seeks to ensure the country's energy security. Rotterdam-based VTTI said in a statement it was "striving"…

Nigeria to Build its First FLNG Unit

Nigerian company UTM Offshore has signed a front-end engineering design (FEED) contract for the development of an FLNG facility in Nigeria with JGC Corporation, Technip Energies, and KBR.This will be Nigeria's first floating liquefied natural gas (FLNG) facility. Africa currently has two FLNG units in operation, the Hili Episeyo in Cameroon, and, as of recently, the Coral Sul FLNG in Mozambique. In Nigeria, the FLNG unit will be used for development of offshore block OML 204.According to Chief Timipre Sylva…