Uncrewed Ships Set to Bring Diversity Boost

The maritime industry’s movement toward remote vessel operations will not only build a more diverse workforce, it will benefit from it, argues marine robotics company Ocean Infinity.Greater workforce diversity, whether it be considered along lines of ethnicity, gender identity, sexuality, age, socioeconomic status, neurotype, physical ability or any other parameter, has shifted over the course of the last decade from a ‘nice to have’ to a fundamental value. The modern view of society that the thought leaders at Ocean Infinity subscribe to, is often characterized as ‘intersectionality’.

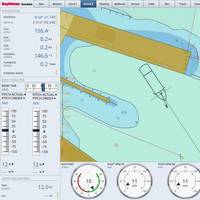

Marine Electronics: New Display Aims to Simplify Ship Docking

Raytheon Anschütz is introducing a new “Docking Display” as an optional feature for the Conning NX navigational ship software.The Docking Display provides a navigator an overview of ship data at a glance and a chart window to facilitate docking. It is designed using Conning NX “widgets” that can be adapted and combined, as needed.“Operators will experience a never before possible situational awareness of the ship, its condition and influencing parameters in the docking maneuver,” said Jörg Schütt, Product Manager at Raytheon Anschütz.

SHI Built LNG-Fuelled Ship with In-house Tech

South Korea shipbuilding major Samsung Heavy Industries (SHI) announced that it has successfully built its first LNG-fuelled vessels with its own technology, proving itself to the eco-friendly shipping industry for its construction competencies and technological prowess.SHI announced on April 29, 2019 that the two LNG-fuelled 113,000 dwt oil tankers delivered to an Asian shipowner early this year just completed the first bunkering at the port of Rotterdam in Netherlands and now begin its operation as ecofriendly vessels. The shipbuilder stated that the two oil tankers are the first LNG-fuelled vessels SHI built at its yard. The order was awarded at the end of 2015…

ClassNK Releases Cyber Security Approach

Classification society ClassNK has released the ClassNK Cyber Security Approach which outlines its basic approach to ensuring onboard cyber security for ships. It was released alongside its Guidelines for Designing Cyber Security Onboard Ships for newbuilding designs as the first part of the ClassNK Cyber Security Series which incorporates requirements for taking onboard cyber security measures.Response to cyber threats is an urgent matter for the entire maritime industry. The…

DNV GL Okays INTELLIMAN Ship Software

DNV GL announced that Samsung Heavy Industries (SHI) INTELLIMAN Ship software complies with the EU-MRV and IMO-DCS regulations.The classification society said in a statement that it issued a factual statement confirming compliance in a ceremony at the SHI R&D Center in Daejeon, South Korea.SHI has been developing smart ship technology since 2016 and it has been applied to certain ships including LNG carriers and large container ships. The INTELLIMAN Ship is an integrated smart ship solution which facilitates data management from fleet operation to life-cycle service both on shore and on board with the latest ICT in a cloud data center…

Hapag-Lloyd Relies on GEA BallastMaster ultraV 500

Germany’s largest shipping company, Hapag-Lloyd, relies on chemical-free UV ballast water reatment from GEA for fitting its container fleet. In April 2015, the BallastMaster ultraV 500 was technically accepted on board Panamax containership London Express (shipboard acceptance approval). “With a throughput of 500 cu. m./hr., our DNV-GL-certified system performs the required ballast water cleaning processes by mechanical pre-filtration with subsequent disinfection of the ballast water using UV-C and ultrasound application,” said Tilo Pfützke, GEA Ballast Water Project Manager.

Hapag-Lloyd Implements UV Ballast Water Treatment

German shipping company Hapag-Lloyd relies on chemical-free UV ballast water treatment from GEA for fitting its containership fleet. In April 2015, the BallastMaster ultraV 500 was technically accepted on board Panamax containership London Express (shipboard acceptance approval). “With a throughput of 500 cubic meters per hour, our DNV-GL-certified system performs the required ballast water cleaning processes by mechanical pre-filtration with subsequent disinfection of the ballast water using UV-C and ultrasound application,” explained GEA Ballast Water Project Manager Tilo Pfützke.

L-3 MSI to Equip Third Quantum Class Ship

L-3 Marine Systems International (L-3 MSI) announced today that it has been awarded a contract to provide a range of navigation, lighting and communication systems for the third ship in Royal Caribbean International’s Quantum class. Built by Meyer Werft at its Papenburg shipyard in northern Germany, the 348-metre-long, 158,000-gross-ton ship is the sister vessel to Quantum of the Seassm, due to be delivered this year, and Anthem of the Seassm, to be launched in 2015, both of which have been similarly outfitted with L-3 equipment. “The three-ship project marks the next step in L-3’s growing support of the world’s premier cruise ship fleets with proven, cutting-edge shipboard system solutions,” said Ulrich Weinreuter, president of L-3 Marine Systems International.

Ship Software Aids Optimal Speed Choice

Eniram’s new product, Optimum Speed Assistant (OSA), is an onboard decision support tool that enables a ship’s crew to attain the optimum speed profile for each voyage, allowing vessels to maintain a constant performance and arrive in port at the right time. The software, which builds on Eniram’s existing Dynamic Trimming Assistant, is the only solution in the industry to combine real-time information about prevailing sea conditions with historical data, allowing operators to sail constantly at the optimum speed profile. This reduces the need for a crew to build in ‘buffer’ time and vary engine speed to ensure on-time arrival in port, a practice which is not fuel efficient. Calculations are served up to the crew via an easy-to-use dashboard and color-coded ‘traffic light’ system.