World’s First Floating Wind Innovation Centre Opens

The world’s first dedicated innovation centre for floating offshore wind has opened in Scotland.Located in the heart of Aberdeen’s Energy Transition Zone, ORE Catapult’s £9 million National Floating Wind Innovation Centre (FLOWIC), delivered in collaboration with ETZ Limited, is designed to help supercharge the development of floating offshore wind technology in the UK, with funding from both the Scottish Government and Innovate UK.Floating offshore wind represents a huge economic opportunity…

Partners Developing Methanol-fueled High-speed Marine Engine

Three marine industry partners are working to develop a concept for a high-speed internal combustion engine for ships that can run on green methanol in a CO2-neutral manner.Rolls-Royce, Woodward L’Orange and WTZ Roßlau have been working since the beginning of 2023 on the new joint project “MeOHmare”, which is receiving eight million euros in funding from the German Federal Ministry of Economics and Climate Protection.Dr. Daniel Chatterjee, responsible for technology strategy and sustainability at alliance coordinator Rolls-Royce Power Systems…

Wind-powered RoRo Vessel Secures €9 Million in EU Funding

A group of partners led by Norwegian shipping company Wallenius Wilhelmsen has secured €9 million in EU funding to support the construction of an environmentally friendly wind-powered pure car and truck carrier vessel.The partners, who are currently working to plan and execute all aspects of building and operating the RoRo sailing vessel Orcelle Wind, aim to have the first-of-its-kind vessel ready for commercial trading within the next five years.The commercial maritime industry is exploring the use of wind power as both a main and auxiliary propulsion source as vessel owners…

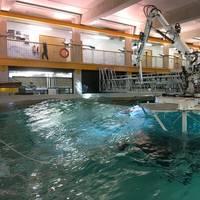

Tech File: A Robotic Reach in Offshore Wind

With a background in subsea and offshore, coming up with new ideas is the norm’ for UK-based engineering consultancy STL (Submarine Technology Limited), writes Elaine Maslin.The last few years have been no different. The company has been focusing on ship-based robotics, including robotic arms. These aren’t just any robotic arms – they’re motion compensated systems for deploying/recovering people and robots to and from fixed or moving objects. That could be wind technicians to…

A Robotic Reach in Offshore Wind

With a background in subsea and offshore, coming up with new ideas is the norm for UK-based engineering consultancy STL (Submarine Technology Limited), writes Elaine Maslin.The last few years have been no different. The company has been focusing on ship-based robotics, including robotic arms. These aren’t just any robotic arms – they’re motion-compensated systems for deploying/recovering people and robots to and from fixed or moving objects.That could be wind technicians to an…

Thordon Bearings Unveils New Water-lubricated Shaft Seal

Thordon Bearings has debuted a new propeller shaft seal for the commercial shipping industry featuring a unique Safe Return to Port (SRTP) design.Completing the COMPAC open seawater lubricated propeller shaft bearing system, Thordon's new BlueWater Seal is described by the manufacturer as a cost effective, commercial grade axial lip seal specifically designed for merchant shipping fleets. It incorporates Thordon’s emergency SRTP capability, first used in the company’s TG100 and…

Largest Wind Turbine Tested on Maasvlakte

The world’s largest wind turbine, Haliade-X, is being tested on Maasvlakte at Port of Rotterdam. This ‘test rig’ was realised via innovative cross-pollination between the American GE Renewable Energy, Sif Netherlands and Pondera Consult.Huge 107-meter-long blades have recently started rotating on Maasvlakte. These are part of the Haliade-X12 MW, the world’s most powerful wind turbine.It is 260 meters high and has a 12-megawatt capacity, sufficient to generate energy to supply electricity to some 16,000 households in the region. As comparison: the wind turbine next to Van Brienenoordbrug has a maximum 3-megawatt capacity.Sif Netherlands is building the foundations for offshore wind farms on the 62-hectare site on Pieter van Vollenhovenweg.

Why Do Accidents Happen in Oil Industry?

As the oil and gas industry strives for cost effective execution in projects and operations while maintaining a high focus on safety and environmental footprint, innovative and smart solutions are needed more than ever. By extracting data and knowledge from all the detailed incident investigations performed over the years, solutions might be just around the corner. DNV GL now invites industry partners to join an industry project (JIP) to identify and have access to updated trends based on a broad range of data, including failure mechanisms, root causes, materials and equipment. The benefit for the industry will be a systematic approach to capturing and sharing learnings from past failures and for the JIP partners to exchange experiences.

Hytorc Aid Testing of Large Turbines

Clemson University has recently taken the lead for making strides in large-scale wind turbine energy testing and construction, as the organization is in the process of completing their revolutionary new testing facility, the Clemson University Restoration Institute (CURI). This multimillion-dollar testing site is capable of performing unprecedented trials on large-scale wind turbines due to the help of HYTORC’s advanced and reliable industrial fasteners, the HYTORC Nut and the HYTORC Washer. The CURI building originally served as a U.S. Navy warehouse used to store nonhazardous materials, and upon completion the facility will become a multimillion-dollar testing site capable of performing unprecedented trials on large-scale wind turbines.

Trelleborg Invests in High-Speed Fender Test Rig

Trelleborg’s marine operation is in the process of building and installing a custom-made high-speed test rig, capable of testing both rubber and foam fenders. The rig is being built in Trelleborg’s new Berryville facility in Virginia, U.S., and represents a substantial investment for the business. When complete, it will be the biggest fender test rig in operation in the industry capable of testing fenders up to the largest commercially available sizes. Richard Hepworth, President of Trelleborg’s marine operation, said: “Amongst quality conscious customers, in the U.S.

Dockside Load Testing with Unique Seaflex

Static load testing is an essential part of many engineering, building and manufacturing businesses – and the shipping, marine and offshore industry is no exception. Water filled weights (also known as ballast bags) provide a flexible method for load testing. Test weights must be sufficiently heavy to ascertain the maximum load of an object, but they should also be reusable and safe to deploy in a test environment. Where there is easy access to a plentiful supply of water, water-filled weights can provide a quick, efficient means to undertake such testing.

Vulkan RATO for Submarine Test Rig

For decades, Vulkan has been a supplier of couplings, not only for Brazilian offshore industry, but also for military applications. Here business mainly focused on conventional drives such as diesel-electric systems for military ships and submarines. Now Vulkan is positioning itself on the Brazilian market as a system solution provider for nuclear propulsion and supply the Centro Experimental Aramar in Iperó with a RATO S 731T and 14 elastic mounts. The Brazilian government is currently planning the construction of a fleet of six submarines with nuclear propulsion.

Strainstall Opens New Production Facility

Strainstall, a part of James Fisher and Son plc, announced the opening of a new production facility based in Bembridge, Isle of Wight. The new 10,000-sqft. facility produces the full range of mooring hooks and mooring units including a bespoke service specific to customer requirements. It is fully equipped with a 7.5te pendant controlled overhead crane, fork lift trucks and high load racking to ensure maximum efficiency and optimum product turnaround. The facility also houses a test rig that can test hook units up to 350te.The rig electronically records all hook data during testing and downloads to a document that gives the customer instant access to the test data. Full testing is carried out in house before being despatched to their customer’s sites.

Optimarin Puts Performance to the Test with DNV

Optimarin has moved to reinforce its market leading position by challenging the integrity of its filter components, through a rigorous program of testing in conjunction with Det Norske Veritas (DNV). The initiative, understood to be unique for a ballast water treatment (BWT) system supplier, saw Optimarin make a substantial investment to put its three leading filter suppliers – Boll & Kirch, Filtersafe and Filtrex - to the test at Goeje Island in South Korea. The motivation was simple; to challenge, and ultimately demonstrate, the reliability of this most crucial BWT system component (giving potential and existing customers real peace of mind), while also feeding the test results back into the Optimarin and individual supplier development teams in a drive for ever-greater performance.

ABB Power2 Completes Type Testing

ABB Turbocharging recently celebrated a milestone in its two stage turbocharging systems. Having equipped the first gas engine to enter commercial service with “Power2” two stage turbocharging equipment, ABB Turbocharging has now carried out Type Testing on a Power2 system in the presence of the Classification Societies on a hot gas test rig at its Technical Center in Baden, Switzerland. In this way, Power2 has passed a major milestone on its way to gaining Type Approval for use on 4-stroke, medium speed marine diesel engines. The Type Test of Power2 took place in early March 2011.

Schat-Harding Sets Freefall Drop Record

Lifeboat and davit manufacturer Schat-Harding has set a world record for lifeboat freefall drop by launching its new FF1200 offshore lifeboat from a drop height of 55 m. With an all up weight of 30 tons, the FF1200 was dropped into the sea from a 55 m test rig at Schat-Harding's Rosendal facility in west Norway. The boat surfaced with powerful positive headway and no internal or external damage. Schat-Harding CEO Ove Roessland says that the 55 m drop height was dictated by the height of the crane available for testing and that the lifeboat was designed to be released over even longer distances.

Hempel Ship Coating Results in Fuel Savings

At a time when fuel savings have more importance than usual, test results for Hempel’s silicone antifouling Hempsail coating application showed an improvement in fuel savings of 10.6 % for a large container vessel. For such a vessel, 10.6 % could amount to up to $2.6 million annually. Tests were run by an independent testing entity, Force Technology, recognized as professional and objective among ship builders and operators. Towing tank experiments compared HEMPASIL silicone based fouling release coating to other generic antifoulings. The question was whether a ship operator would achieve fuel savings by applying HEMPASIL, and how much. Results were much better than expected, and they were reproducible.