Alfa Laval's Adaptive Fuel Line

Though fuel-saving practices like slow steaming are widespread, energy efficiency continues to be a pressing concern. Vessel fuel bills remain high – and will likely become even higher for those sailing in Emission Control Areas after January 2015. Catastrophic engine damage due to cat fines is also on the rise, along with safety worries related to multi-fuel operation. Yet in the face of these complex and interrelated issues, the Alfa Laval adaptive fuel line offers new levels of savings and protection.

Fuel costs, emission legislation and cat fine difficulties are all deeply intertwined. With HFO already at a premium, everything possible is being done to enable slower steaming and reduce fuel consumption. Meanwhile, emission legislation is forcing the use of even more expensive distillates, as well as the use of low-sulphur HFO. The fact that the latter has a higher average cat fine content can be tied to a growing number of cat fine attacks, which have increased despite the revision of ISO fuel specification 8217 to a 60 mg/kg Al+Si limit.

“Part of what we’re seeing is a consequence of the effort to curb emissions, which is making traditional fuel cleaning even more demanding,” says Niclas Dahl, Alfa Laval Market Unit Manager, Marine Energy. He refers to a recent study by Man Diesel & Turbo’s PrimeServ, in which cat fines had a confirmed role in 84% of 226 investigated cases of poor engine cylinder condition. “These cat fine attacks are an energy issue as well as a safety concern, because the wear deteriorates engine efficiency even if it doesn’t lead to catastrophic failure.”

Alfa Laval has been working to break the cat fine trend, but also to find energy opportunities amidst today’s more complex fuel practices. “When it comes to the fuel line, energy efficiency and protection are often two sides of the same coin,” says Dahl. “Our R&D has therefore focused on using the synergies that exist. Through a combination of new thinking and new technology, we’ve created a truly adaptive fuel line that saves energy as well as the engine.”

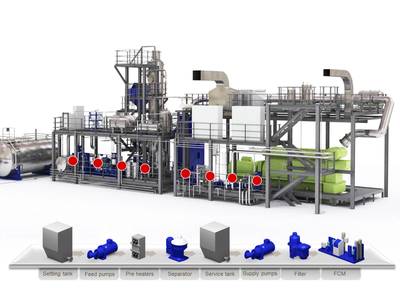

The Alfa Laval Adaptive Fuel Lne

There is much that can be done to optimize individual fuel line components, such as choosing separators with Alcap functionality. Moreover, much can be done with the fuel line construction to prevent cat fine attacks, such as ensuring that tank floors are slanted and that return pipes extend from the tank bottom rather than the top. According to Dahl, however, “Finding large-scale energy benefits and really maximizing protection requires looking further than traditional component roles.”

Alfa Laval’s recently launched FCM One booster, Dahl says, is an excellent example of such thinking. “The FCM One goes beyond traditional booster capabilities, including those of our original Fuel Conditioning Module,” he explains. “It works with multiple fuels, reacts to multiple parameters and handles multiple levels of information, which gives it a much broader influence on the fuel line as a whole.”

The idea of incorporating the whole defines not only the FCM One, but also the Alfa Laval adaptive fuel line of which it is a part. The Alfa Laval adaptive fuel line saves energy and improves protection by four distinct means: feed optimization, system supervision, multi-fuel management and waste fuel recovery.

Since the adoption of slow steaming, most vessels spend little time at full engine load. Nonetheless, fuel lines are constructed and operated as if full load were the norm. “This is an opportunity missed, and not only because feed pumps and separators that run on full consume unnecessary energy,” says Dahl. “Decreasing the flow rate through the separator increases the time the fuel spends within it, which improves the removal of particles.”

This is the principle utilized by FlowMate, a new Alfa Laval system that adjusts the flow of fuel to match the engine load. “By using automatic control and variable frequency drives to reduce the flow at partial load, we make use of the available synergy,” Dahl says. “The principle is obvious. Why use more energy for fuel cleaning when using less energy will mean even better cat fine removal?”

In addition to FlowMate, the Alfa Laval adaptive fuel line has dedicated heater control that keeps the fuel’s temperature at the recommended 98° ± 2°C. “This parameter is surprisingly overlooked on board,” says Dahl. “Without proper control, the fuel temperature can easily drop to 85°C, which necessitates a 40% flow reduction to maintain separation efficiency.”

Even when the flow is optimized and separation efficiency is high, spikes in cat fine levels are impossible to rule out. In rare cases they may be caused by off-spec fuels, though they are more likely to occur when latent cat fines in the tanks are stirred up by rough seas. Preventing such attacks from damaging engine cylinders is essential, because damaged surfaces reduce combustion efficiency and may eventually result in engine failure.

To keep cat fines from entering the engine, another new system is incorporated into the Alfa Laval adaptive fuel line. Catguard accurately measures cat fine levels at several pre-engine sampling points, warning of any elevation. Such real-time measurement enables crews to take immediate countermeasures, as well as to trace the root causes of the problem.

A similar function is provided by the FCM One, whose engine-specific monitoring of fuel consumption takes into account the pulsations of the fuel injection system. “While not a measurement of engine efficiency per se, the monitoring of fuel consumption quickly indicates when efficiency losses occur,” says Dahl. “Like Catguard, it allows immediate action to be taken and root causes to be traced.”

“Put simply,” Dahl says, “crews now have the tools stop the cat fines that threaten the engine and its efficiency, and they can detect increasing fuel consumption at an early stage, regardless of the cause.”

Multi-Fuel Management

The FCM One has yet another important role in the Alfa Laval adaptive fuel line, especially for vessels that will sail in Emission Control Areas. When multiple fuels are used on board, the FCM One safeguards fuel changeover and enables automatic blending for an economical match of a given sulphur target.

“Multi-fuel operation creates difficulty for operators, since residual and distillate fuels have very different characteristics,” says Dahl. “The changeover between fuels must be well controlled, especially when it comes to viscosity, or there will be alarms and delays that result in more burning of expensive distillate.”

Sophisticated automation and temperature control are central to an energy-efficient changeover. The FCM One uses one controller, a single algorithm and integrated cooling to keep viscosity within a tight range – even when changing between different fuel blends. “The FCM One puts everything into one system, including the option of an electronic fuel record book to prove ECA compliance,” says Dahl. “ That means uninterrupted transitions where less distillate is consumed, even when there are changes in engine load.”

Waste Fuel Recovery

Feed optimization, system supervision and multi-fuel management – combined with individually optimized components – create a fuel line that truly adapts to changing conditions. This in itself saves a great deal of energy, even as it provides better protection for the engine.

What remains is to recoup the small losses that occur at various points in the system, which account for 0.5 to 2% of a vessel’s total fuel consumption. In this respect, PureDry is the crown jewel of the Alfa Laval adaptive fuel line, as it allows virtually all of this oil to be recovered with ISO 8217 quality. At present, PureDry is the only equipment capable of recovering the HFO fraction of waste fuel oil in accordance with MEPC.1/Circ.642.

“PureDry is a unique and long-awaited opportunity for ship owners and operators, since it lets them get the maximum amount of energy from the fuel they bunker,” says Dahl. “All that remains is bilge-quality water and a tiny fraction of super-dry solids, because everything else is returned as reusable fuel.”

With PureDry, Dahl says, a large container vessel with an engine capacity of 64 MW can save up to USD 670,000 per year in fuel costs alone, plus an additional USD 67,000 in waste disposal costs.

A Total Approach

The complete Alfa Laval adaptive fuel line is a highly responsive and integrated system, whose design, automation and quality are assured by Alfa Laval. All components are steered with the new Alfa Laval Touch control system, whose graphical touchscreen interface provides two-touch access to all functions and an easy overview of all fuel line parameters.

What matters most, however, are the tangible savings this new configuration offers. Using Dahl’s example of a large cargo vessel with an engine capacity of 64 MW, feed optimization and waste fuel recovery can lead to a total annual fuel savings of well over USD 880,000. Added to this are the fuel savings through system supervision and multi-fuel management, which might be as much as USD 400,000. Although protective savings via FlowMate and Catguard are more difficult to quantify, the prevention of a severe cat fine attack could avoid costs for repair, downtime and off-hire running into the millions.

“The Alfa Laval adaptive fuel line marks a new chapter in Alfa Laval’s fuel handling leadership,” says Dahl. “By widening the perspective and taking a comprehensive approach to optimization, Alfa Laval has created a state-of-the-art solution to today’s energy efficiency and fuel quality concerns. Savings, safety and compliance are incorporated in a single system that handles the full spectrum of fuels and operating conditions. That puts operators in full control, both of fuel line processes and of opportunities for energy optimization.”