Subsea Job Sets World Record

The world’s deepest hot tap operations on a pressurized pipeline have been performed on the Ormen Lange field in the Norwegian Sea during early August.

“Being able to connect a spur to a producing pipeline yields significant cost savings,” said Bjørn Kåre Viken, vice president for marine technology and operations in StatoilHydro.

Enhanced flexibility in deep water is another advantage of such operations, two of which were conducted on Ormen Lange in a depth of 860 metres. The operations were done to tie in a new subsea template in the southern part of the Ormen Lange field to the existing infrastructure on the sea bed.

“Remotely operated hot tapping utilises much of the same technology as the manual procedure using divers,” Viken explained.

“However, the technology has been further developed and tailored to the pressure and other conditions encountered at these depths.”

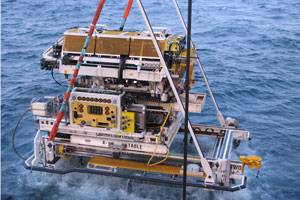

The two hot taps were monitored and controlled from the surface, assisted by 100 sensors, 23 cameras and 18 subsea computers deployed on the seabed to transmit data via heavy duty cables.

“We’re a world leader in this technology, which will also be important for future projects,” Viken explained. “Substantial cost savings can be achieved when developing mature areas. That’s because the method allows existing pipelines to be used, so marginal fields can be tied back to older infrastructure with good capacity.

“Using remotely operated hot tapping is also safer than deploying divers, and means the technique can be employed in deeper waters.”

Preparatory work for the operations paid great attention to risk analysis and understanding. The technology has also been carefully tested.

“This is an example of the way we can develop new solutions by challenging existing technology,” says Viken, who is very pleased with the work done. It demonstrates StatoilHydro’s leading-edge expertise and ability to execute major projects.

Hot tapping operations involve doing repairs, replacements or tie-ins on pipelines which remain pressurised. That makes it possible to avoid expensive shutdowns and simplifies the tie-in of new pipeline systems to existing infrastructure.

The Ormen Lange gas development in the Norwegian Sea ranks as one of the biggest and most demanding industrial projects ever conducted in Norway.

No installations are visible above water on the field. All of them stand on the seabed in depths of 800-1,100 metres.

Hydro was the development operator for Ormen Lange, with Shell taking over as production operator. StatoilHydro carries out subsea operations there on Shell’s behalf.

StatoilHydro 28.9169%, Shell 17.0375%, Petoro 36.4750%, Dong 10.3420% and ExxonMobil 7.2286%