Alan C. McClure Expands Analysis Capabilities

Alan C. McClure Expands Computational Fluid Dynamics Analysis Capabilities.

Alan C. McClure Associates (ACMA) has announced that the company has recently expanded its Computational Fluid Dynamics (CFD) analysis capabilities with a 50% increase to computational power, expanding their High Performance Computing (HPC) cluster to 48 processor cores, backed by 92GB of memory. This expanded capacity allows the company to handle larger, more complex models. According to ACMA Vice President Darrel Harvey, the company’s investment in both the hardware and software technology has resulted in substantial cost savings for clients in modeling and computational time.

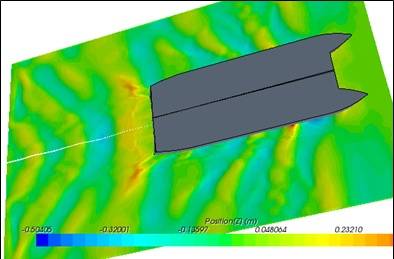

“The company’s new analysis capability will enable ACMA to accurately determine the effect of viscous flows and non-linear waves on vessel hulls and in internal tanks,” said Harvey. “All of the hydrodynamic loads and pressures due to fluid flow are calculated directly, with no reliance on drag coefficients or proprietary modeling factors. Also inherent in a CFD model are shielding effects due to the ‘upstream’ members inhibiting flow onto the ‘downstream’ members. CFD models are typically full scale, which eliminates many common modeling uncertainties inherent with traditional scale model testing.” Harvey went on to note that ACMA has recently provided a number of analyses that involved the calculation of ship hull resistance predictions.

“With CFD capabilities, it’s easy to modify a model and see how the change impacts vessel performance,” said Harvey. “From this, we can fine-tune the hull form to better optimize its efficiency and, ultimately, the required installed horsepower to meet a speed requirement. This practice has been applied to the design of bulbous bows as well. Known as a ‘Virtual Tow Tank’, this kind of study is used to adjust a model to minimize actual tow tank costs.

ACMA President Scott McClure added, “Tow tank time and model costs can run as much as four times more than our ‘Virtual Tow Tank’ costs. So by doing some CFD analysis and fine-tuning the hull form, only one model needs to be made and the testing time for result verifications is reduced by 75%.”

ACMA uses the STAR-CCM+ software, the flagship CFD package from CD-Adapco. Within STAR-CCM+, the flow field is calculated using RANS (Reynolds Averaged Navier Stokes) equations to directly determine the flow effects. Several industry-accepted turbulent flow models can also be applied to the system. ACMA has integrated the CFD analysis into its already extensive toolbox of analysis tools which includes Finite Element Analysis (FEA) and 3D Diffraction mooring analysis (fully coupled).