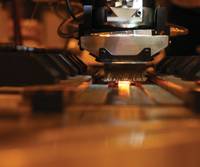

3D Printing: Navy Builds Up Additive Manufacturing on Ships

The U.S. Navy has long valued the potential of additive manufacturing (AM) and 3D Printing.AM refers to the depositing of material layer by layer to create an object. For the Navy, it’s not practical to carry every replacement part for every system on a ship, and it can be difficult to forecast if or when parts will fail. AM provides a flexible source of supply in being able to make parts instead of ordering them and waiting for them to arrive, especially for warships at the far end of the supply chain.

AMI Wins $3.5 Million Defense Contract

Auburn Manufacturing, Inc. (AMI) has won a multiyear contract to supply over 200,000 yards of AMI-SIL fabric to the Puget Sound Naval Shipyard (NSY) in Bremerton, Washington, for use in hot work operations during ship repair. The contract, which could total as much as $3.5 million over the next five years, "reflects the continued confidence the Department of Defense has in our products," said Kathie Leonard, AMI's President and CEO. "We've been supplying hot work safety fabrics to the Navy for over twenty years under various contracts, and are now well over 1.5 million yards. Keeping its U.S.

U.S. Navy: The Business Case for a Titanium Ship

Participants at a workshop exploring the use of titanium structure for ships found that it is not only possible to construct a ship hull from titanium—or Ti, it could be cost effective. The workshop was sponsored by the Office of Naval Research and hosted by the University of New Orleans, where an ONR research program on titanium ship structures is being conducted. Representatives of the shipbuilding industry, titanium suppliers, Navy, Coast Guard and Air Force labs, and academia discussed and examined materials, processes and applications. Most ships today are primarily made from steel.

Ship Scrapping – Recycle Circuit Boards, Electronic Equipment

Boliden is currently ramping up a new plant adjacent to its existing electronic scrap recycling facility at the Rönnskär copper smelter in northern Sweden - an expansion that will almost triple recycling capacity from 45,000 metric tons to 120,000 metric tons a year, making it the largest e-scrap recycling facility in the world. Rönnskär is an integrated metallurgical complex, which smelts and refines metals from mined copper concentrates and from recyclable materials like metal shred and electronic scrap.

Coatings: Metal Fusion Helps Stop Corrosion

New advances in metal fusion technology produce a metalized coating with no porosity, which can be applied at rates similar to those achieved by airless painting practices. The substrate temperature does not affect the process, and there is no curing time. The competitive process results in extremely long term near permanent corrosion protection, which is designed to be competitive in price with conventional corrosion systems. High speed metalizing of a variety of substrates can be accomplished rapidly under harsh field conditions. As there is no cure time required for the process, which can be used to apply up to 35 mils with only one coat, the application time is often much reduced from a conventional corrosion prevention system.