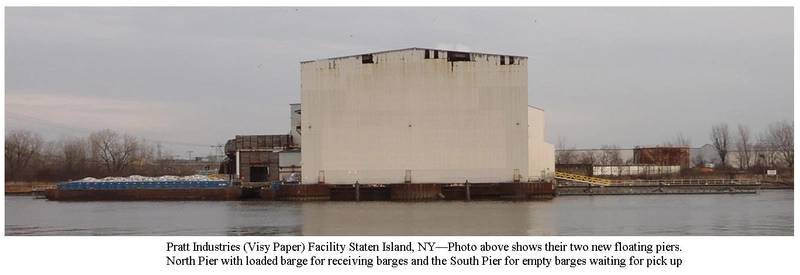

New Commercial Floating Piers in Staten Island

Davit Engineering, a division of Davit Sales Inc. recently completed the design and construction drawings for two new floating piers in Staten Island for receiving loaded barges of paper from NYC for recycling. The piers are 140 ft. long x 6 ft. wide floating structures the first of which commissioned just days prior to the worst storm in the New York area’s history, Hurricane Sandy. It was a serious and successful test for this new structure which incurred no damage as a result of the storm’s winds and tidal surge.

The plan for these piers Mr. Al Avitabile, president of DSI explained was based on reusing six existing monopoles already in place, three on either side of the receiving facility as the sole anchoring points for the two new piers. This eliminated the expense of driving additional piles and helped facilitate the regulatory agencies approvals. The ensuing design, which was the brain child of Davit's VP of Engineering Tony Stipich, also made use of a new generation of rubber fenders to develop a “shock absorbing” barge landing and unloading facility for Pratt's Staten Island, NY facility.

The design concept is based on the requirement to absorb the maximum berthing energy of an approaching vessel with a minimum predetermined impact force. The selection of the rubber fender locations, shape and material along with an innovative system of pile attaching arms made it possible and safe to install such a floating pier at a fraction of cost of a conventional pile pier. The two floating piers installed consist of a berthing pier on the North end of the facility and a lay-up pier on the South end. In case of traditional “fixed pier/piled structures” the cost of the North and South piers would have been practically the same. With Davit’s concept the South pier is less expensive because it does not have to absorb the same berthing energy of the North pier.

An additional benefit of Davit Engineering’s floating pier design is that the freeboard of the landing pier is always the same relative to the arriving and departing barges such that the boarding and disembarkation conditions are consistent from one berthing to the other. The berthing barge will never get in contact with the hot-dipped galvanized structure of the pier which is certain to minimize the maintenance cost. The deck of the pier is made of fiberglass grating to prevent icing conditions. The pier is mounted on heavy duty foam filled floats making the pier virtually unsinkable.

The project was realized thanks to Pratt Industries’ management team who recognized the benefits of the proposed concept and Whiting Turner who supervised its construction and installation.

www.davitsales.com