Largest Ferry Employs Common-Rail Technology

Daewoo Shipbuilding & Marine Engineering Co., Ltd. (DSME) of Korea, one of the world’s largest shipyards, has ordered four common-rail 12V48/60CR Tier-II propulsion engines from MAN Diesel & Turbo SE. The prime movers will power a new RoPax ferry for Tunisian ship owner COTUNAV (Compagnie Tunisienne de Navigation).

The ferry will have a capacity of 3,200 passengers and 1,060 vehicles, and a top speed of 27.5 knots. At 210 × 30 m, the vessel will be the world’s largest ferry and contain a shopping centre, restaurants, swimming pool and multiple entertainment facilities. Delivery is due in the first half of 2012. The newbuilding will reinforce COTUNAV’s existing main routes between Tunisia, Italy and France.

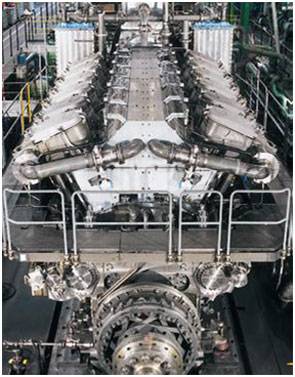

The common-rail engine and injection system

The common-rail engines have an output of 14,400 kW each and represent the cutting edge of MAN Diesel & Turbo technology. The engines are well-proven and have amassed many references, especially within the cruise-ship segment.

The 48/60CR injection system uses the latest common-rail technology that allows independent setting of injection timing, duration and pressure for each cylinder. This flexibility allows optimisation of the 48/60CR’s fuel consumption, NOx and smoke emissions at any point on its operating profile, especially at part-load.

Common-rail safety concept

The common-rail system is based on an intelligently designed safety concept that features screened or double-wall high-pressure pipes, and flow-limiting valves to prevent uncontrolled injection. The system has redundant high-pressure pumps as well as twin-type pressure and speed sensors to ensure engine operation, even in the event of failures.

Electronics

The 48/60CR is equipped with SaCoSone, MAN Diesel & Turbo’s proven, cutting-edge engine-management system. SaCoSone is an innovative system that gathers all functions of modern engine management together. It offers:

• integrated self-diagnosis functions

• maximum reliability and availability

• simple use and diagnosis

• quick exchange of (plug-in) modules

• trouble-free and time-saving commissioning

NOx-eliminating features of the 48/60CR

Retarded injection timing delays combustion-heat release, thus lowering combustion chamber temperature peaks and NOx emission. A new piston design provides a higher compression ratio and faster temperature reduction after ignition, further reducing NOx formation. Variable valve timing enables variations in the opening and closing of the inlet valves, thus providing an additional contribution to the minimisation of the SFOC versus NOx emission trade-off.

Propeller

The RoPax ferry is a twin-screw vessel and the order includes two CP propellers that will be delivered by ALPHA. The specified propellers are MAN’s Alpha CP Propellers type VBS1800-ODF, with a propeller diameter of 5,600 mm and a power density corresponding to 1,169 kW/m2. Each propeller is driven by a twin-in/single-out gearbox and will be powered by two of the 12V48/60CR main-engines.

The ferry is designed with two separate engine-rooms with the propeller shaft-lines having different lengths of well over 40 metres. The final propeller-blade design will be hydrodynamically optimised and carefully balanced with a special focus on propulsion efficiency, low noise, and cavitation levels. The total weight of the propeller equipment amounts to almost 300 tons.

Propulsion control and manoeuvring will be managed by MAN’s Alphatronic PCS system courtesy of a complete setup with control consoles in the engine-control room, the forward bridge and the bridge wings.