Partners to Develop Large Scale LCO2 Carriers

POSCO, Hyundai Mipo Dockyard, Korea Shipbuilding & Offshore Engineering, Lloyd’s Register and the Liberian International Ship & Corporate Registry have set out to jointly develop liquid carbon dioxide (LCO2) carriers to meet the demands of increased global carbon storage and utilization technology.Through their recently signed memorandum of understanding (MOU), POSCO will develop new steel material and relevant technology for storage tank, which are core technologies for the large size of LCO2 carrier…

Auction at Damen Shipyards

Dutch shipbuilder Damen Shipyards Group held an auction of left-over surplus materials as part of its commitment to sustainability.Stock manager Martijn van Tilborg explains, “Auctioning left over shipbuilding materials might not be the most obvious step towards greater sustainability, but it actually plays a significant role – what we are doing, effectively, is recycling. As well as the important environmental benefits, this is a great opportunity for our clients, for example, to stock up on spare parts in a cost-effective manner.”He explains that previous drives towards more ecological performance has led Damen to take great care to optimise usage of materials ordered for the shipbuilding process.

POSCO Daewoo to Supply Marine Equipment to Indonesian Shipbuilder

POSCO Daewoo has signed a memorandum of agreement (MOA) to supply shipbuilding materials worth US$150 million to Penataran Angkatan Laut (PT PAL), Indonesia’s largest state-run shipbuilder, according to a report in Business Korea. Under the contract, the Korean trading company will supply engines and other parts necessary for shipbuilding, and its partner PT PAL is going to build 10 patrol boats and one combat support ship with the provided materials before delivering them to Indonesian ministries including the Indonesian Navy and the Ministry of Communication and Information Technology. The 11 ships will be taken over by the Indonesian government once they are built.

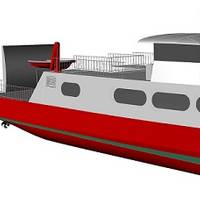

Collaboration Fuels Environmental Ferry Development

SP Technical Research Institute of Sweden has long been engaged in research aimed at energy efficient vessels by increased use of lightweight shipbuilding materials. A major step forward was a recently completed concept development project where SP Fire Technology conducted life-cycle cost analysis and a comprehensive fire risk assessment for a car ferry in carbon fiber composite. The research project was performed within a Swedish-Danish-Norwegian cooperation MARKIS and received additional funding from SP and the Danish Maritime Fund.

Seaspan Selects IFS Applications to Support $8B Navy Deal

IFS North America said that Seaspan has selected IFS Applications as its Shipbuilding materials requirements planning (MRP) solution. IFS Applications was chosen because it provides a powerful project-based solution (PBS) with the ability to control cost and schedule in real-time, enhancing Seaspan’s ability to efficiently meet customer requirements. This capability will help Seaspan deliver on the recently awarded $8 billion Federal Government shipbuilding program to build non-combat vessels for the Canadian Coast Guard and Royal Canadian Navy.

Mitsubishi to License Shipbuilding Tech to India

Mitsubishi Heavy Industries, Ltd. (MHI) has agreed with L&T Shipbuilding Limited (LTSB), the shipbuilding arm of India's Larsen & Toubro Limited (L&T), under which MHI will provide a broad range of technological support to LTSB for construction of commercial vessels. The two companies are slated to sign the technical collaboration agreement tomorrow. MHI has recently been proactively promoting development of its engineering business, centering on technology licensing, while LTSB…

ClassNK Approves First Corrosion Resistant Steel

April 27 (Tokyo) - ClassNK announced today that it had issued the world’s first type approval for corrosion resistant steel to the new NSGP®-1 steel manufactured by Nippon Steel Corporation’s Oita Works . The approval certifies that the new steel, which has been specifically designed for application on the inner bottom of the cargo oil tanks of crude oil tanker, complies with the IMO’s new performance standard for corrosion resistant steels. New requirements for preventing corrosion…

As SOLAS Deadline Nears, More Composite Use is Expected

Composites have been utilized in various applications in the shipbuilding industry in order to meet countless requirements of shipyards and ship owners. Composites have found their way into areas such as hull design for smaller vessels to modular bathroom units on larger vessels. Research and development with composites has also created Trevira fabric. Composites continue to evolve along with the shipbuilding industry, and one should expect to see more wide spread use of this material in years to come. In order to better understand composites one must review the creation of this modern material, and then one can examine the uses of this product. The general definition for composite material is the combination of two or more materials in order to create a completely new material.

KOTC to Tender for Four Vessels

Kuwait Oil Tanker Company (KOTC) said it would issue a tender in the next few months to build four 300,000-tonnes crude oil tankers as part of plans to upgrade its fleet. Chairman Abdullah Al Roumi said Asian shipbuilding companies were expected to take part in the tender. He said each tanker was expected to cost between $120 million-$130 million. 'It will cost more this time compared to the previous cost of $100 million for a tanker because the price of shipbuilding materials has increased worldwide,' Roumi said. He said nine other tankers are already being built and will be delivered in 2007 and that KOTC planned to build two more tankers in the future. Source: Trade Arabia

Kuwait to Build New Crude Oil Tankers

The Kuwait Oil Tanker Company (KOTC) plans to build four new crude oil tankers with a total capacity of 1.2 million tons, Kuwait News Agency (TUNA) reported on Wednesday. According to the report, each tanker will cost 120 million to 130 million U.S. dollars depending on technical specifications, while the previous cost was 100 million dollars per tanker. KOTC Chairman Abdullah al-Roumi attributed the higher prices to rising shipbuilding materials worldwide. KOTC will open a tender for the project in the next few months and shipmakers from the Far East are expected to submit their bids, said al-Roumi. As many old tankers were put out of service, KOTC has set up a plan to upgrade and enlarge its fleet. Source: Xinhua

LR Provisional Rules for SPS

Lloyd’s Register, in conjunction with Intelligent Engineering, Ltd, has developed a set of provisional Rules for new construction and ship repair using steel sandwich construction. Entitled Provisional Rules for the Application of Sandwich Panel Construction to Ship Structure, the Rules were approved in early 2006 by a specially convened sub-committee of Lloyd’s Register’s Technical Committee, comprising independent experts drawn from across the industry. Sandwich Plate System (SPS) is a technology created by UK-based Intelligent Engineering Ltd in which two metal plates are bonded to a solid elastomer core. The elastomer provides continuous support to the plates and stops local plate buckling, eliminating the need for stiffeners.