For connection of stainless steel and steel tubes above and below deck, VOSS Fluid provides the VOSSFormSQR tube forming system. The solution is certified for marine and offshore applications, even frequently-changing assembly personnel achieve process-reliable connections.

Leaky connection points on ships and wind parks can quickly grow into enormous problems. Aiming to ensure that a leak does not occur in the first place and to prevent time and cost intensive localization and repair work, VOSS Fluid GmbH developed the VOSSFormSQR tube forming system. The system has been in use for more than 12 years without a single known leak, VOSS said.

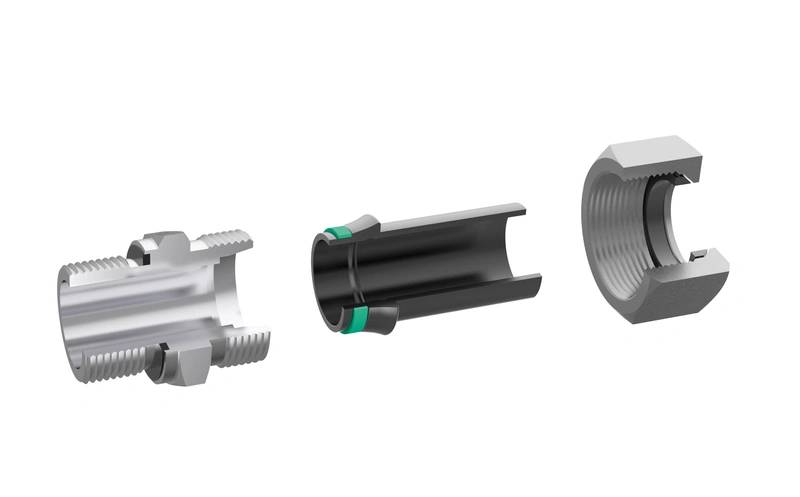

The forming process is as simple as it is reliable: In the first step, conventional hydraulic tubes are given a 24-degree tube contour on one end. The VOSSForm 100 tube forming machine takes care of the forming automatically. The operator merely needs to select the appropriate tool, pushes the tube against the limit plate and presses the start button. After that, the machine forms the VOSSFormSQR contour plastically on the tube. To complete the pre-assembly, the formed tube end is provided with an additional soft seal. Then comes the final assembly: The fitter sets the machined tube with the face on the base of the coupling connector. It ensures a stable fit and secure limit stop. He then tightens the nut. Since this is an SQR function nut with an integrated clamping ring specially developed by VOSS Fluid, the tube is automatically tightly radial-clamped during the final assembly. That results in an especially secure, high-grade connection. The noticeable increase in force when tightening the nut indicates the end of the assembly process to the fitter. This practically excludes over- and under-assembly. Another important advantage: When compared to the systems normally available in the market, the assembly distances are significantly reduced with the tube forming system from VOSS Fluid. Results are achieved that are nearly identical to comparable taper couplings. This reduces the power requirement along with the assembly time and is especially important under difficult installation conditions such as overhead assembly, in ergonomically unfavorable positions and in particularly tight and compact installation spaces.

VOSSFormSQR tube fittings provide a leakproof connection even in the fine range, the manufacturer said. The high leakproofness can be attributed, for one, to the additional soft seal; it provides advantages as compared to a purely metallic seal. It effectively prevents sweating of the joint - and that for a longer than average time. That is because the tight abutment of the tube in the pipe connection base, the so-called primary metallic throttling, causes a damping of the pressure-swing tension. This concept that is unique throughout the market prevents the flexing or rinsing-out of the soft seal, guaranteeing leakproof connections long term, according to VOSS. On top of that, the tube connection system meets the highest demands placed on load capacity and security. After all, due to the constant vibrations marine and offshore applications have to have particularly high flexural fatigue strength. With VOSSFormSQR the clamping ring in the coupling nut and deep tube clamping ensure reliable resistance to high bend change stresses: On the one hand, an above-average long part of the tube is supported by the coupling connector. On the other, the clamping ring clamps the tube radially on the circumference, which already absorbs dynamic loads before the critical area. That prevents a potential breakage through the notch effect and increases the compressive strength and security against fracture. VOSS Fluid holds approvals for all shipbuilding classes from the International Association of Classification Societies (IACS). Under the umbrella organization IACS, internationally recognized classification organizations have combined to stipulate the application-specific requirements and test procedures, with the aim of defining the international quality standards.

The VOSSFormSQR which is designed 100 percent for security, load capacity and durability, also features special finish quality of the tube connection components. VOSS coat, a coating based on zinc and nickel, defies even the most aggressive media and guarantees an especially high degree of corrosion resistance. By doing so, the finish does not only reach the highest Corrosion Protection Class of K5 as per DMA Standard Sheet 24576; it even exceeds the required resistance values against white and red rust both under laboratory conditions as well as in more demanding test runs. For some marine and offshore applications this means: The VOSS finish protection is so effective that steel tubes with VOSS Fluid tube fittings, contrary to conventional practice, partially no longer need to be over-coated.

For applications in stainless steel, the tube forming system VOSSFormSQRVA is used. In this case, all fitting components are made out of stainless steel and exhibit completely identical product characteristics and advantages. The highest degree of process reliability and leakage security, the greatest resistance to loads along with corrosion resistance - these attributes make the tube forming system from VOSS Fluid the optimal solution for shipbuilding and the offshore industry.