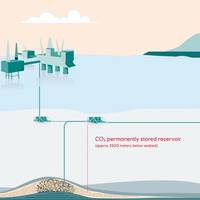

Northern Lights CCS: Trailblazing the Path to Europe’s Net Zero Emissions

In the global quest for achieving net zero emissions and slowing down global warming, carbon capture and storage (CCUS) technology has emerged as an important solution. Among the notable projects being developed in the field is the Northern Lights offshore carbon capture and storage project in Norway, a country with long experience with offshore CO2 storage.The transition to a sustainable energy future requires innovative solutions that go beyond simply halting fossil fuel projects.

LNG Storage Tank Market to Reach $17.5Bn by 2025

LNG storage tank market is expected to grow from USD 12.5 billion in 2020 to USD 17.5 billion by 2025, at a CAGR of 7.0%, during the forecast period.The major factors driving the LNG storage tank market include increasing demand for LNG from various end-use industries, such as steel, power, and energy. Furthermore, the growing trade of LNG will also drive the demand, said a report by MarketsandMarkets.APAC is projected to be the leading LNG Storage Tank Market during the forecast period. The growth in the APAC region can be attributed to the rising demand for LNG from various end-use industries including energy, power and steel.The presence of a robust industrial base…

LR Awards AiP to DSME for VLEC Design

Classification society Lloyd's Register said it has awarded Approval in Principle (AiP) to South Korean shipbuilder Daewoo Shipbuilding & Marine Engineering (DSME) for its 98,000-cubic meter very large ethane carrier (VLEC) design with new cryogenic material High Manganese Austenitic steel (High MnA) and sloshing-free tank, the first VLEC design to use this type of material.DSME’s 98,000 m3 VLEC design is made of DSME-patented ‘Type B’ tank so it can operate with partial loading due to a sloshing-free tank design making vessel operations flexible and efficient…

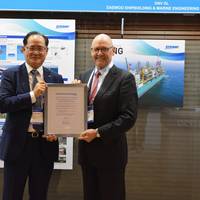

DNV GL Grants AIP for DSME Ethylene Carrier Cargo Tank

At Gastech trade fair in Houston, DNV GL presented South Korea’s Daewoo Shipbuilding & Marine Engineering Co. Ltd. (DSME) with Approval in Principle (AIPs) certificates for two new 98,000 cubic meter (cbm) ethylene carrier cargo tank designs. In a hand-over ceremony at the DSME booth, Odin Kwon, Chief Technology Officer (CTO) of DSME, received the AIP certificates from Johan Petter Tutturen, DNV GL – Maritime’s Business Director Gas Carriers.“This is another great milestone in our longstanding relationship with DNV GL…

LR Awards DSME AiP

LR has awarded Approval in Principle (AiP) to Daewoo Shipbuilding & Marine Engineering Co., Ltd (DSME) for its 98,000 m3 Very Large Ethane Carrier (VLEC) design with new cryogenic material High Manganese Austenitic steel (High MnA) and sloshing-free tank, the first VLEC design to use this type of material.DSME’s 98,000 m3 VLEC design is made of DSME-patented ‘Type B’ tank so it can operate with partial loading due to a sloshing-free tank design making vessel operations flexible and efficient, and facilitating multi-port loading/unloading requirements.

Hyundai Heavy, LR Eye LNG-fueled Future

Hyundai Heavy Industry (HHI) Group, with the support of Lloyd's Register (LR), is responding to the increasing interest in the development of the global supply of liquefied natural gas (LNG), following the introduction of the International Maritime Organization’s (IMO) NOx and SOx emission limitations, by being at the forefront of developing innovative ship designs. This month Hyundai Mipo Dockyard (HMD), part of the HHI Group, will deliver of the world’s largest LNG-fuelled ship, a 50,000 dwt bulk carrier with a high manganese LNG fuel tank.

LR Approval for GTT's Mark V Technology

GTT, the world leader in the design of membrane containment systems for the maritime transportation and storage of LNG (Liquefied Natural Gas), announces that its new containment system Mark V has earned a General Approval from the classification society Lloyd's Register. This is the second validation for GTT's latest technology, after Mark V was recently granted a similar General Approval from DNV-GL. The Mark V technology was developed after a number of years of research and development. It is an optimized version of the Mark III system and its sister Mark III Flex. As with the Mark III and Mark III Flex, the Mark V technology is composed of a double insulation with reinforced polyurethane foam.

GTT’ Mark V Earns DNV GL General Approval

GTT, a designer of membrane containment systems for the maritime transportation and storage of liquefied natural gas (LNG), announced that its new containment system Mark V has been granted General Approval for Ship Application (GASA) by classification society DNV-GL. GTT called the validation by DNV-GL of the Mark V technology a major step toward its commercialization following two cooperation agreements GTT signed during the first half of 2015 with the shipbuilders Hyundai Heavy Industries and Samsung Heavy Industries to confirm the industrialization of the system. After some years of research and development, the Mark V technology is an optimized version of the Mark III system and its sister Mark III Flex.

HHI to Industrialize GTT’s Mark V Technology

GTT (Gaztransport & Technigaz) has signed a cooperation agreement with the South Korean Shipbuilder Hyundai Heavy Industries (HHI) for the industrialization of GTT’s new Mark V technology. A similar partnership was signed a few weeks ago between GTT and Samsung Heavy Industries. The agreement includes the development and qualification of an innovative welding robot for the primary stainless steel and secondary invar membranes. The robot will permit the optimization of the welding process and a reduction in construction time. After some years of research and development, the Mark V technology is an optimized version of the Mark III system and its sister Mark III Flex.

Articulated LNG Barge Proposal Gets Class AIP

ABS gives Approval in Principle (AIP) to a newly proposed LNG articulated tug & barge re-gasification vessel that facilitates the use of cleaner burning fuel. The concept vessel, introduced by Waller Marine Inc., has the ability to load LNG from existing LNG terminals, liquefaction facilities or traditional LNG carriers and transport the LNG to existing tanks, traditional LNG carriers, trucks or marine vessels using LNG as a fuel. The barge also is equipped for regasification of LNG directly to a pipeline or to a power plant. An additional feature will be the use of natural gas as a fuel in the dual fuel engines of the tug to drive the tug-barge unit.

Great Ship: Great Ships of 2003

Ship Owner Mediterranean Shipping Co. S.A. MSC Linzie is the first vessel of a new vessel type developed and designed by Hanjin which adopts the new Panamax length design of 294.05 m. Apparently the design series and Hanjin's well-established reputation in this niche has proved attractive, as the company has, to date, logged orders for 24 ships of the new design. As mentioned above, its length is the maximum for Panama canal, i.e. 294 m. So it has been designed to move flexibly both in Pacific Ocean and in Atlantic Ocean through Panama canal, which is one of the main feature that makes it popular among the operator. This ship offers the maximum intake of 5,060TEU.

Bouygues Offshore Logs New Contract

Technigaz, a wholly-owned subsidiary of Bouygues Offshore, will build a Liquefied Natural Gas (LNG) tank in Palos de Frontera, Spain under a contract awarded by ENAGAS. This contract, for a total amount of EUR 40 million (Bouygues Offshore's share: EUR 28 million) will be performed by a Joint-Venture of Technigaz (70%) and Initec (30%). The customer, ENAGAS, is the only LNG importer in Spain so far. This turnkey contract covers Engineering, Procurement, Construction and pre-commissioning of a full-containment storage tank for the extension of the LNG import terminal located in Huelva harbor on the Atlantic Ocean. The inner tank will be made of 9% nickel steel with perlite insulation to maintain the LNG at a temperature of -163(degree)C…

Gas Ship Design Challenges

Sophisticated they may be, but the designs of today's LNG, LPG and ethylene carriers are in reality based on the simple parameters of the ideal gas laws governing the relationships between pressure, temperature and volume. In addition, the materials in direct contact with the cargo must be matched with the properties and characteristics of the cargo. The key to the designs is the atmospheric boiling temperature of the cargo, i.e. ambient for fully pressurised LPG, -33 deg. C for anhydrous ammonia, -48 deg. C for propane, -104 deg. C for ethylene and -163 deg. C for LNG. In terms of fleet numbers the total number of gas ships is small compared with oil tankers, general cargo ships or passenger vessels.

Great Ship - Hanjin Muscat

Built by Hanjin Heavy Industries for the transportion of liquefied natural gas (LNG) between Oman and Korea, Hanjin Muscat is a 918 ft. (280 m), 68,524-dwt ship using Gaz Tranport's No. 96-2 membrane cargo containment system. The vessel was built with only four cargo tanks, contained within a complete double side/bottom/bulkhead/deck trunk structure, with top and bottom wing tanks. The side and bottom spaces from integral port and starboard water ballast tanks, divided by the duct keel. This double-hull structure not only protects the tanks from external damage, but insulates the outer hull against critical steelwork fractures cased by the low temperatures (-163 degrees C and atmospheric pressure) at which cargo is transported.