PYPLOK Reduces Assembly Times and Installation Costs

Chris Peitchinis outlines the benefits of using PYPLOK mechanically attached connectors which reduce new installation or maintenance repair costs.

PYPLOK connectors are attached cold, in seconds, by swaging the connector on the pipe or tube with a hydraulic hand held tool. All the labor and associated costs of a conventional welded connection are eliminated.

• No special skilled labor required vs. qualified welder.

• Actual swaging time is measured in seconds vs. hours for a welded joint.

• No special hot work permits

• No fire watch personnel required.

• No leaks as a result of stress fatigue cracks as seen in welds.

• No cost to x-ray welds.

• No cost to rework welds.

The PYPLOK system has been successfully used in wide variety of industries such as Marine & Offshore, Steel Industry, Oil & Gas and Refinery to name a few. Applications range from hydraulic oil, lubrication, fuel lines, steam trace, and many other fluids and gases.

PYPLOK is a solution for O.D. tube from 1/4” to 2”, Metric tube from 6mm to 90mm and NPS pipe from 1/4” to 3”. Due to the nature of the design the connector is dependent on outside diameter and the wall can be virtually any thickness. PYPLOK connectors are suitable for pressures up to 10,000 PSI (690 bar) depending on the size and safety factor.

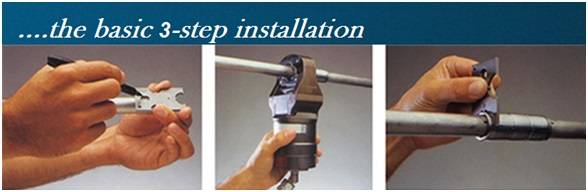

The 3 step installation process is fast and simple after cutting and deburring the pipe or tube.

1. Mark the insertion depth - Mark the insertion depth on the pipe using the Inspection/Marking Gauge.

2. Pressurize tool - Insert the pipe in the PYPLOK connector, position the tool over the connector and pressurize the tool to swage the PYPLOK connector on to the pipe.

3. Quality assure the connection - Quality assure the swage with the Inspection/Marking Gauge.

Note: The actual swage cycle time varies by size but typically from 10-30 seconds.

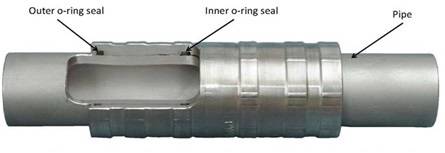

PYPLOK connectors have two elastomeric o-ring seals at each end. The inner o-ring seal closes off all the potential leak paths and the outer o-ring seal on the end of the fitting acts as a back-up and an “Environmental” seal to prevent sea water or other contaminants from entering between the connector and the pipe.

O-ring materials are available in two elastomeric compounds:

• Viton O-rings -15°F to 400°F (-26°C to 205°C)

• EPDM Compound E0962 (for steam) -60°F to 400°F (-51°C to 205°C)

Cr (VI) - free plating

PYPLOK connectors are supplied in carbon steel with Cr (VI)-free plating, 316 stainless steel, and Copper Nickel (CuNi) 70/30. Other materials are available upon request such as Duplex and Super Duplex stainless steel.

Shapes and Configurations

PYPLOK conforms to standard end connections, SAE, NPT, DIN and flange patterns in accordance with SAE Code 61/ISO 6162-1, SAE Code 62/ISO 6162-2, ISO 6164 and also with ANSI Class.

Apart from standard shapes such as tees, 45˚ and 90˚ elbows and reducers, custom connectors are also available.

Safe Technology

PYPLOK is a safe, cold work connector technology and a permanent, tamper proof connection with no bolts or nuts to become loose over time.

Intelli-Swage

PYPLOK connectors are installed with a hand held, portable, pre-engineered swage tool which assures repeatability, leak-free and reliable connections. There is no need to rely on the strength of the installer to tighten bolts or nuts.

Certifications

PYPLOK connectors are certified by leading classification societies such as DNV, ABS, BV CCS, RMRS and LR for Marine & Offshore and TSSA, ABSA and CRN Registration for industrial use.

Tube-Mac Piping Technologies Ltd., is the manufacturer of PYPLOK connectors and swaging tools and together with its global PYPLOK distribution network, it services customers worldwide.

tube-mac.com

pyplok.com