By the Numbers: Small Shipyard Grants

Small shipyards in the U.S. are critical to the nation’s maritime operations and economic security. Typically family-owned and employing less than 1,200 workers, America’s small shipyards support more than 400,000 jobs, employ more than 100,000 Americans directly and contribute tens of billions in gross domestic product, according to the U.S. Department of Transportation’s Maritime Administration (MARAD).In an effort to help support these vital assets, MARAD’s Small Shipyard Grant Program provides funds to help drive efficiency…

MarAd Grants Fuel U.S. Shipyard Growth

The U.S. Department of Transportation’s Maritime Administration (MARAD) announced $19.6 million in grants to support capital improvements at 28 U.S. small shipyards as a part of its Small Shipyard Grant program. The grants enable small shipyards to modernize equipment and processes to fuel future growth. “These grants help create jobs in America’s small shipyards, which play a significant role in our country’s maritime sector,” said U.S. Transportation Secretary Elaine L. Chao.In 2013, U.S. shipbuilders produced $37.3 billion in gross domestic product.

Fuel Catalyst Makes Engines More Efficient

Engines are designed to run on refinery grade fuel. At the time fuel is refined, it is at its purest state; however, it deteriorates rapidly as it oxidizes and is attacked by a host of organisms (bacteria, yeast, molds), that change the molecular structure of the fuel. The Fitch Fuel Catalyst (FFC) reverses this natural aging process by inducing a chemical reaction using a patented metal alloy catalyst (not a liquid additive) that reforms diesel fuel, creating a more combustible, cleaner burning product as evidenced by the end-user comments presented in this document.

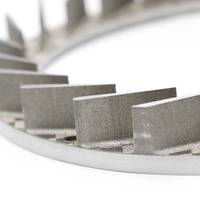

3D Printing Enables Quick Turbocharger Repair

The first 3D-printed nozzle ring for marine turbochargers has been developed using exotic super metal alloy, enables the reconstruction of worn out components for shorter repair times. According to the technology’s developer, Tru-Marine, the premature erosion of nozzle rings has been a commonly reported problem, and in such situations, spare part replacements are often unavailable and come with long lead times at high costs. The company has therefore developed proprietary processes in 3D printing…

Petrobras Setbacks Threaten 2014 Production Goals

Brazilian state-run oil company Petroleo Brasileiro SA suffered another setback in its effort to boost oil output last month when Italian contractor Saipem SpA dropped a 2.3 km steel pipe into the Atlantic Ocean. On March 16, the rigging used to wrangle the pipe into position on a floating oil platform failed, and the high-grade, metal-alloy tubes plunged about 1,800 meters (5,900 feet) to the seabed, a total, crumpled loss. The pipe itself was worth about $2 million but the cost of the accident will be much higher, two sources with direct knowledge of the situation told Reuters. By setting back efforts to expand Roncador, Brazil's No. 2 oil field, by at least a month, Petrobras will lose tens of millions of dollars in oil output, salaries and equipment leases when it can least afford it.

Coatings: Metal Fusion Helps Stop Corrosion

New advances in metal fusion technology produce a metalized coating with no porosity, which can be applied at rates similar to those achieved by airless painting practices. The substrate temperature does not affect the process, and there is no curing time. The competitive process results in extremely long term near permanent corrosion protection, which is designed to be competitive in price with conventional corrosion systems. High speed metalizing of a variety of substrates can be accomplished rapidly under harsh field conditions. As there is no cure time required for the process, which can be used to apply up to 35 mils with only one coat, the application time is often much reduced from a conventional corrosion prevention system.

Gas Ships: Teekay Enters LNG With Tapias Acquisition

Teekay Shipping Corporation has entered into a definitive agreement to acquire Naviera F. Tapias S.A., a leading independent owner and operator of LNG carriers and crude oil tankers in Spain. Teekay has also entered into an agreement with the shareholders of Tapias to establish a 50/50 joint venture that will pursue new business in the oil and gas shipping sectors, focusing specifically on the Spanish market. The Tapias acquisition will establish Teekay's presence in LNG shipping, one of the fastest growing sectors of sea-borne energy transportation. It will position the company as a key supplier of LNG shipping to Spain, the world's third largest importer of LNG, and provide a strategic growth platform for Teekay.

IZAR Christens Fourth LNG Carrier

IZAR’s Puerto Real Shipyard recently christened the LNG carrier Cadiz Knutsen, with representatives of the owners Knutsen OAS and Marpetrol and the final client, Unión Fenosa Gas. This ship will transport up to 138,000 cu. m. of gas at –163ºC, and is the fourth LNG carrier built at IZAR, and the second one of those built at Puerto Real facilities. There is a third unit under construction at this shipyard for the shipowner Fernandez Tapias. The vessel will transport gas from the Damieetta port liquefaction plant in Egypt to the gasification terminals in Ferrol and Sagunto. It will take 15 days and 10 days respectively for the ship to cover the routes at design speed, 19.5 knots.