Kongsberg Develops Green Engine Room Simulator

The Kongsberg Maritime Simulation & Training department has developed a Green Ship Engine Room Simulator (ERS) model based on a Wärstilä 12RT-flex 82C low-speed common-rail engine, built for a Panamax container ship of 4800 TEU, with reefer capacity of 800.

The scenario for the simulated ship model is a modern Green Ship that is financed and operated by a ship owner who is concerned about environmental issues, and who has built a fuel efficient / low-emission container ship using well-proven, commercially available technical solutions. The simulated ship has a high normal operating speed of 26 knot and the propulsion machinery is adapted for all ambient temperature conditions, ranging from arctic (-40°C) to tropic (45°C), allowing new trading routes. The new ERS model offers highly realistic training based on the above conditions, to ensure optimal performance whilst reducing emissions. The RT Flex simulator model also includes a Sankey diagram, making it easy to visualize the energy efficiency of the engine room plant.

"Although many Kongsberg Maritime ERS models offer Green Ship functionality, the RT-flex model features the most comprehensive fuel efficiency and emission reduction functionality that we have developed so far," explained Leif Pentti Halvorsen, Product Manager for Engine Room and Cargo Handling Simulators, Kongsberg Maritime. "Our increased focus on Green Ship simulation is a result of higher interest from environmentally conscious owners, who will be using more efficient engines like the Wärstilä 12RT-flex in the future."

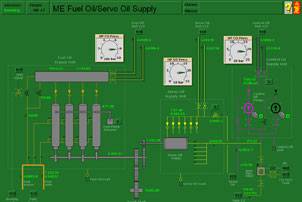

Instead of the usual mechanically-controlled fuel injection pumps and exhaust valve drives of Wärtsilä RTA engines, the RT-flex82C has an electronically-controlled common-rail system, meaning that the engine room operation differs from that of other ships, so there is a requirement for specific training on this system. The new ERS model simulates the Wärtsilä Engine Control System (WECS) which triggers the electro-hydraulic rail valves for the respective functions, in addition to simulating a wealth of technical aspects including waste heat and thermal oil tank heating system. The model also simulates an exhaust converter of the SCR (Selective Catalytic Reduction) type, cutting the NOx emission by about 90%.