Chart Industries Expands its Partnership with TECO 2030

TECO 2030 and Chart Industries have expanded their existing cooperation agreement on Chart’s Cryogenic Carbon Capture™ process technology (CCC), to include Chart’s offer of liquid cryogenic fuel storage and supply systems, as well as Howden’s hydrogen solutions.Under the expanded agreement, Chart, Howden (a Chart Industries Group company) and TECO 2030 will combine their expertise to offer improved ship efficiencies and reductions in carbon emissions.Chart, including Howden, has solutions including leading compression technologies…

FEED Completed for Delfin FLNG Vessel

Delfin Midstream (“Delfin”) has informed that the FEED has been completed for the Newbuild FLNG Vessel for the Delfin LNG project offshore Louisiana, in cooperation with Samsung Heavy Industries and Black & Veatch.Delfin LNG project has been described as a brownfield Deepwater Port "requiring minimal additional infrastructure investment to support up to four FLNG Vessels producing up to 13 million tonnes of LNG per annum."Commenting on the completion of the FLNG FEED Delfin said: "The tripartite cooperation has been successful in developing a robust…

Chart Joins SEA\LNG

The global manufacturer of equipment Chart Industries has joined SEA\LNG, the multi-sector industry coalition accelerating the widespread adoption of liquefied natural gas (LNG).Peter Keller, SEA\LNG chairman, commented: “We are thrilled to welcome another member from North America. Chart is a highly respected equipment and solution provider working across the LNG value chain and we look forward to working together with a company that is at the heart of the energy revolution.”Chart is a key equipment and systems provider to applications that utilize clean burning, economical natural gas.The liquefaction technology that is used includes specialized heat exchangers…

Novatek Signs LNG Equipment Deal

The Russian natural-gas company Novatek and Atomenergomash, a mechanical engineering division of the Rosatom State Corporation, have signed a memorandum on strategic partnership and localizing the fabrication of critical equipment for liquefied natural gas (LNG) production.Novatek said that under the memorandum, the two companies will cooperate in the long term to localize the fabrication of pumps, heat exchangers and other equipment for Novatek's LNG projects at Atomenergomash's facilities.The Memorandum notes the results already achieved on the fabrication of coil-wound heat exchangers and medium-tonnage cryogenic pumps, and establishes the obligations of the Parties on design…

Novatek Kicks-off Yamal LNG's Train 3

Russia's Novatek has begun production of the commissioning LNG from its third 5.5 million mt/year train at the Yamal LNG project, bringing the plant's total capacity to 16.5 mln tonnes of LNG per year.“We have successfully launched all three LNG trains at our flagship Yamal LNG project according to our revised early launch schedule,” Novatek’s head Leonid Mikhelson said.Russia’s largest independent natural gas producer said in a press release that the third LNG train was launched more than one year ahead of the planned original schedule. All three technological trains have been launched on budget, it said.This fact is unprecedented for the industry plagued by massive cost overruns and project delays…

Total in Talks to Buy Iranian LNG Project

Total is in talks to buy a multi-billion dollar stake in Iran's partly-built liquefied natural gas (LNG) export facility, Iran LNG, seeking to unlock vast gas reserves. The French oil major -- the first of its peers to strike deals in Iran after sanctions -- seeks entry into Iran LNG at a discount to the pre-sanctions price in exchange for reviving the stalled project, two sources with knowledge of the matter said. A third source confirmed Total was in the running for a stake, alongside several other oil majors, but any deal was still some way off. Total declined to comment. Iran's National Gas Export Co. (NIGEC), a central stakeholder in the project, did not respond to requests for comment by email and phone.

Bear Head LNG GHG Management Plan Approved

Bear Head LNG Corporation Inc. (Bear Head LNG) received Nova Scotia Environment’s (NSE) approval for its Greenhouse Gas (GHG) Management Plan for its liquefied natural gas (LNG) facility on the Strait of Canso in Richmond County, Nova Scotia. The GHG Management Plan provides Bear Head LNG’s strategy for managing GHG emissions through technology selection, design of the facility, and operations. “Approval of Bear Head LNG’s GHG Management Plan is welcome news,” said Greg Vesey, Managing Director and CEO of LNGL and President of Bear Head LNG. “Bear Head LNG is designing a best-in-class LNG facility, utilizing state of the art technology.

Eagle LNG Seeks Greenlight for LNG Exports

Eagle LNG Partners has submitted an application with the US Department of Energy (DOE) requesting long-term, multi-contract authorization under Section 3 of the Natural Gas Act to engage in exports of natural gas in the form of liquefied natural gas (LNG). The application seeks authorization to export up to 49.8 Bcf, or ~1.0 million tons per annum (mtpa), of LNG per year to both free trade agreement (FTA) and non-free trade agreement (non - FTA) countries. The authorization is for Eagle LNG Partners’ proposed FERC-jurisdictional LNG export facility in Jacksonville, Florida, and requests authorization from the DOE to export LNG on its own behalf and as an agent for other organizations.

ABS, Golar Strike FLNG Deal

ABS Group subsidiary Genesis Technology Solutions, Inc. (GenesisSolutions) won a contract by Golar LNG to develop an intelligent maintenance strategy for the company’s new fleet of floating LNG (FLNG) vessels usingthe GoFLNG floating liquefaction technology. ABS Group will assist Golar LNG with implementing the Maximo computerized maintenance management system (CMMS) to support its asset management program. ABS Group will provide a model for asset data, criticality rankings, spare parts analysis, a risk-based inspection strategy, failure mode and effects analysis and a maintenance program for the first GoFLNG facility under construction, the Hilli, which will operate off the coast of Cameroon, as well as for future vessels.

FLNG Birth of a Market

FLNG deal-making has been sporadic since Woodside Petroleum at the end of 2013 delayed a final investment decision for the giant Browse FLNG project off Northwest Australia. The previous year had seen go-aheads for most of the floating liquefied natural gas projects (FLNG) underway today, including Shell’s Prelude FLNG — Woodside’s choice, it seems, of a liquefaction solution for fields 200 kilometers offshore. Yet Prelude, “the first project out”, might not be first to produce.

Golar Moves Ahead with lucrative FLNG Project in Cameroon

Golar LNG Limited inform that with regards the signing of a Heads of Agreement with Societe Nationale de Hydrocarbures ("SNH") and Perenco Cameroon ("Perenco") for the development of a floating liquefied natural gas export project in Cameroon that took place on 24 December 2014 an agreement has now been reached with the support of the Boards of both Golar and Perenco on the material commercial terms and conditions for the project. The Tolling Agreement which defines the material commercial terms and conditions for the project is now subject to finalisation with SNH and government approval. Similarly, the Midstream Gas Convention setting…

Delfin LNG Proposes Gulf Coast’s First Offshore LNG Facility

A potential deep-water port LNG export project for the Gulf of Mexico has submitted applications to the Maritime Administration and the United States Coast Guard for approval. Delfin LNG LLC has submitted an application to the Maritime Administration (MARAD) and the United States Coast Guard (USCG) to construct, own, and operate the Delfin LNG Project (Port Delfin) under the Deepwater Port Act. The primary purpose of the proposed project is to provide a safe and reliable facility to liquefy natural gas for export to free trade agreement (FTA) and non-FTA nations under authorizations from the US Department of Energy. The deepwater port…

Lloyd’s Releases Guide for FLNG Facilities

Lloyd’s Register published a rule set to guide the design, construction and operation of floating liquefied natural gas (FLNG) facilities – the biggest, most complex floating structures ever seen – meaning natural gas will now be safer, cheaper and have a lower environmental footprint, the company said. Launched today, Lloyd’s Register’s Offshore Rules for FLNG vessels and facilities are based on a real-world projects and extensive work with key industry alliances. The Offshore Rules for FLNG reinforce Lloyd’s Register’s position at the forefront of new maritime and energy technology, building upon the work the company has performed with numerous LNG firsts, such as classing the first LNG fuelled tanker, Argonon.

Wison and Black & Veatch to Jointly Pursue Offshore LNG Projects

Shanghai-based Wison Offshore & Marine Ltd., a subsidiary of the Wison Group, announced the signing of a Memorandum of Understanding with Black & Veatch to jointly pursue barge-based natural gas liquefaction facility projects on an exclusive basis. Under the agreement, Wison will hold responsibility for barge design and engineering, overall project management, construction, delivery and financing of the integrated facility. Black & Veatch will provide the basic and detailed LNG plant designs…

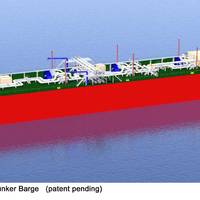

Barge-mounted Natural Gas Liquefaction

EDF Trading with EXMAR intend to seek small-scale LNG export opportunities in North America using barge-mounted natural gas liquefaction. The mobile gas liquefaction plants are developed by EXMAR, Wison and Black&Veatch. The aim would be to bring mobile, self-contained liquefaction units to LNG import terminals in the US using existing pipeline, tank and jetty infrastructure to enable LNG export. EDF Trading and EXMAR have secured the support of the Wison Group for the provision of turn-key EPCIC services for the construction and commissioning of barge-mounted liquefaction plants. These plants will make use of Black&Veatch’s proven PRICO® single mixed refrigerant liquefaction technology but no commercial terms of the arrangements were disclosed.

Waller Marine to Develop New LNG Terminal Facility

Waller Marine, Inc., through its LNG development subsidiaries, Waller Energy Holdings, LLC and Waller LNG Services, LLC, (the Company) has initiated activities on its first natural gas liquefaction (LNG) facility to be constructed on a 175 acre site the Company has acquired at the entrance point of the Calcasieu Ship Channel in Cameron Parish in Southwest Louisiana. Using small-scale liquefaction technology, the Company plans to install nominal 500,000 gallon per day LNG trains in phases as the market and demand for marine LNG fuels inevitably expands.

DNV to Class World's First LNG FPSO

DNV has been contracted to class the Petronas LNG FPSO (Floating Production, Storage, Offtake) vessel to be built by Korea's DSME. The unit will be built by DSME in Korea and is destined for the Kanowit field offshore Sarawak, Malaysia. It is expected to be the world’s first floating liquefaction unit in operation when completed in 2015. The Petronas FLNG will be 300m long and 60m wide and will be moored 180km from shore. It is designed to produce 1.2 million tonnes a year (mtpa) of LNG, boosting Malaysia’s total LNG production capacity from 25.7 mpta to 26.9 mpta. The scope of the DNV contract includes the floating structure, mooring arrangement and natural gas liquefaction technology. • ship-to-ship offloading equipment suitable for LNG transfer at sea.

First Russian LNG Cargo Journeys to Japan

The first Russian LNG cargo for delivery to Japan has been successfully loaded from the Sakhalin II LNG plant into the Energy Frontier LNG carrier. The Energy Frontier left the Prigorodnoye port on 29 March for the Sodegaura terminal in Tokyo Bay, with a cargo of some 145 thousand cubic metres of LNG intended for two of the Company's foundation customers - Tokyo Gas and Tokyo Electric. The LNG was loaded through the 805-metre long jetty at the Prigorodnoye port, which was purpose built for the year-round export of liquefied natural gas (LNG) and oil. "This is a key milestone, the culmination of many years of effort by the Russian federation…

Astillero Sestao Shipyard Developing New LNG Design

represent a step ahead in gas carriers. membrane systems. diesel engines whose operation is combined with a redundant re-liquefaction plant. after comprehensive comparisons among them. also operational and environmental. propulsion. Sestao technical team claims. carrier. can be integrated into a conventional LNG design. discharge to floating terminals and their solutions have been studied, such as partial fillings in cargo tanks or the response to steam turbine durins dynamic positioning operation. projects related to gas transport under pressure.

PDVSA Sees Shell, Mitsubishi LNG JV Deal

PDVSA expects to sign a final JV deal with Royal Dutch/Shell Group and Mitsubishi Corp. to develop the $2.7B Mariscal Sucre LNG project by the end of Nov.2003. PDVSA recently decided to use Shell's gas liquefaction technology in the project.

Exmar, Excelerate Alliance for FLSO Solution

Exmar announced the formation of an alliance to advance its efforts in the development of floating liquefaction solutions. Exmar has formalized a relationship with its long-time LNG partner, Excelerate, and with Black & Veatch, a provider of natural gas processing and liquefaction technology. “This partnership forms a basis for the development of the first floating liquefaction, storage and offloading solution in the world" said Nicolas Saverys, Chief Executive Officer of Exmar NV. The FLSO combines the liquefaction process, storage tanks, loading systems, and other LNG-related infrastructure into a single floating unit. Exmar is a diversified and independent shipping group serving the international gas and oil industry…

LNG FPSO Ordered

Höegh LNG announced that it has entered into agreements with major contractors and formally started the engineering and design for its first LNG FPSO Unit (Floating Production Storage and Offloading), with the objective to design and construct the worlds’ first LNG FPSO. “Our strategy is to develop Höegh LNG’s business model from pure LNG transportation into offering also solutions for LNG production and floating regasification terminals”, says Sveinung Støhle, President and CEO of Höegh LNG AS. The proposed project will consist of a ship shaped offshore classed structure with the capacity to treat and liquefy a well stream of approx 2.5 billion cubic meters pr. year, which will give an annual production of approx 1.6 million tons of LNG and approx 0.5 million tons of LPG.

Linde forms Global Alliance with SBM

Linde has formed a Global Alliance with Single Buoying Mooring Inc. (SBM) to develop and market Floating Production, Storage and Offloading units (FPSO) for the growing Liquid Natural Gas (LNG) industry, based on Linde's proprietary natural gas liquefaction technology. After having finalized a generic concept for a LNG FPSO with a yearly capacity off app.2.5 million metric tons of LNG, global marketing efforts will start as of today. The FPSO is designed for any conventional natural gas composition and aims at offshore natural gas fields with recoverable reserves of 1 trillion cubic feet or more. Under the Global Alliance Linde contributes the FPSO topsides including gas pretreatment…