Hydrex Conducts Underwater Stern Tube Seal Repair in Algeciras

Last month, a Hydrex diver team carried out an underwater stern tube seal repair on a ro-ro ship berthed in Algeciras, Spain.The ship was suffering from an oil leak, making an on-site repair necessary. Using a Hydrex flexible mobdock, the team was able to carry out the entire operation on-site and underwater, saving the owner an expensive and time-consuming trip to drydock.Once the operation was approved, all preparations were handled swiftly and the lightweight equipment was…

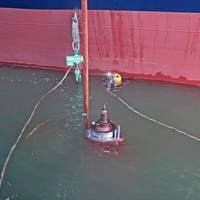

Hydrex Completes RoRo Bow Thruster Replacement in Rotterdam

Last month a Hydrex team replaced the bow thruster of a 191-meter roro ship during the vessel’s stop in Rotterdam. Using one of the company’s workboats, the diver/technicians carried out the operation on-site.The team mobilized to the ship’s location on the workboat loaded with all the needed equipment. After the team set up a monitoring station, the divers started the operation with a detailed inspection of the bow thruster and tunnel. In the meantime, initial preparations were…

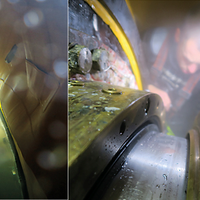

Tech File: Hydrex Completes Mobile Stern Tube Seal Replacement

Hydrex mobilized diver/technician teams to vessels in the Netherlands and Australia to carry out stern tube seal replacements. In Flushing the repair was carried out on a 200-meter car carrier, and in Port Burnie, Tasmania, on a 188-meter RoRo vessel.Both ships were leaking oil, making an on-site repair necessary. Using a Hydrex flexible mobdock they were able to carry out these operations on-site and underwater, saving a trip to drydock.Despite the remote location of the RoRo vessel…

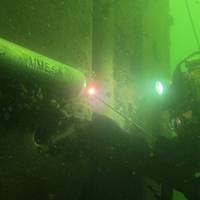

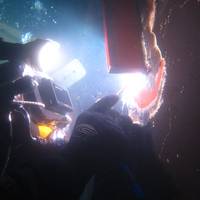

Underwater Propeller Repairs in Winter Conditions in Europe

In just over a week Hydrex diver/technicians traveled to Finland, Germany, the Netherlands and France to assist shipowners with damaged propeller blades. On two bulkers the blades were cropped while on a third bulker and a general cargo vessel the bent blades could be straightened.In all cases the best solution was offered to the customer to restore the propeller’s efficiency as close to the original condition as possible.One of the propeller blades of a 180-meter bulker was severely bent. A fast, on-site solution to restore the propeller’s balance and efficiency was needed.

Hydrex Ready to Mobilize at Port of Rotterdam

To enable a fast mobilization throughout the entire Rotterdam port without delaying a ship’s commercials operations, Hydrex dive support vessels are stationed in Rotterdam. These workboats are fully equipped with hydraulic cranes, winches, a dive spread and control room.This allows Hydrex to offer simple maintenance operations as well as repairs on all parts of the underwater ship propulsion system and the hull. Hydrex operations are class approved and carried out alongside or at anchorage while commercial activities continue without disruption.

Underwater Bow Thruster Removal in Rotterdam

Last month a Hydrex team removed a bow thruster from a 170-meter container ship. This was done during a stop in Rotterdam. The unit needed to be overhauled and the operation had to be carried out within a very short window that would fit the schedule available to the vessel’s owner.The team mobilized to the ship’s location using a workboat loaded with all the needed equipment. These workboats are fully equipped as dive support stations with hydraulic cranes, winches, nautical and communication equipment and a dive control room.

Hydrex Earns Belgium, Netherlands Approvals

In close communication with the Dutch Ministry of Infrastructure and Water Management, Hydrex has developed a new method to clean propeller blades underwater. This method complies with the strict environmental regulations in Belgium and the Netherlands. As a result, the company has been given permission to clean propeller blades in both countries.The traditional approach in the propeller maintenance industry is to polish the blades with a grinding disk which can be quite damaging to the propeller.

Underwater Bow Thruster Reinstallation

A month after a Hydrex diver/technicians removed the bow thruster of a 300-meter container vessel a team once again mobilized to Italy. They reinstalled the overhauled unit underwater with the use of the company’s flexible mobdock technique.The available time window for the removal of the bow thruster in October was very short because of the tight schedule of the vessel’s charterer. The time required to perform the operation therefore needed to be brought back to the absolute minimum. For this reason the job was split in parts, performed in different ports.

Hydrex: Stern Tube Seal Repairs

Recently Hydrex carried out six stern tube seal operations all across Europe in a very short time span.Here is a review of two of the repairs: In Flushing the four damaged seals of a 268-meter container vessel were replaced underwater with our flexible mobdock technique. In Antwerp a seal operation was performed on a trimmed 185-meter general cargo ship. Both repairs were carried out in cooperation with the OEM.Repair in stages to fit the ship’s scheduleBecause the container vessel had a very tight schedule, Hydrex proposed to carry out preparatory work during an earlier stop in Dunkirk.

Underwater Maintenance Operations: Big and Small

Hydrex frequently performs large, complex projects across the globe, but the company says its smaller projects are equally essential. Daily, its divers conduct smaller maintenance operations including installation or replacement of anodes, blankings, replacement of transducers, propeller cleanings and all types of inspections.InspectionsBuilding upon conventional technical skills and know-how while also taking advantage of the latest technology, Hydrex offers a unique hull monitoring service.

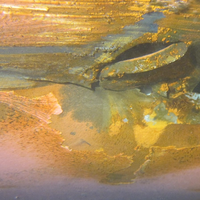

Hydrex's Doubler Plates Keep Ships Sailing

Underwater repair specialist Hydrex says when hull damage leads to the classification society to only allow temporary repair, there is a practical solution that allows ships to continue operations until a permanent repair can be scheduled. Recently called upon to inspect damage to the stern thruster area of a 195m ro-ro ship during a scheduled stop in Antwerp, the Hydrex investigation revealed a large crack in the welding seam on the edge between the hull plating and the thruster tunnel. To repair the vessel, Hydrex was able to fabricate a 600mm x 300mm doubler plate, on-site.

Underwater Bow Thruster Repairs

Hydrex diver/technicians can perform a wide range of repair or maintenance work on all types of thrusters. An entire unit can be overhauled, propeller blades or seals can be replaced or repair work on a specific part of a thruster can be performed on-site. All of these repairs can be carried out without the need to drydock the vessel. Bow thruster operations are carried out using lightweight flexible mobdocks that close off the thruster tunnel on both sides. This allows divers to work in a dry environment around the unit.

Ship Owners Are Modifying Propellers to Meet EU MRV Requirement

Belgian underwater repair specialist Hydrex says it is carrying out more modifications to a ship’s underwater areas and equipment in addition to the company’s more common damage rectification work. The increase in this type of work - to propellers, in particular – follows the recent introduction of the European MRV regulation which has seen more shipowners look at ways of further reducing fuel consumption (and emissions) when operating to and from European ports. The EU MRV (Monitoring, Reporting, Verification) regulation entered into force in July 2015.

Underwater Seal Repairs Avoid Drydock and Off-Fire Costs

Following a spate of stern tube seal failures, Antwerp-based Hydrex has reiterated its capability in carrying out repairs to stern tube seals during a ship’s routine port visit, saving the expense and loss of revenue of unscheduled drydocking. Stern tube seals can suffer undue wear or damage due to a variety of causes, causing water ingress and oil leaks. With ever-tightening environmental regulations resulting in heavy penalties for oil pollution, rapid and timely repairs are essential.

Hydrex to Expand Antwerp Facility

Antwerp Port Authority has supported Hydrex Underwater Technologies’ plan to expand its existing 5000m² site on Asiadok on the River Scheldt with new workshops and offices. As part of its expansion, the result of organic growth over the past two years, Hydrex has also refurbished its dive support workboats and increased its manpower by 25 percent to strengthen its diver-technician capability. Hydrex Chairman Boud Van Rompay said, “The new facility together with our recent recruitment drive is consequent of market demand for swift and cost-effective underwater hull and running gear care.

Delay Averted with Underwater Sterntube Renewal

Hydrex Underwater Technology has assisted an excavation vessel hemorrhaging oil from a stern tube seal entangled with steel wire to pass safely through the Panama Canal. The 156m long, Dutch-owned vessel was unable to make the canal transit until the propeller shaft seal had been repaired, potentially delaying operations and resulting in financial penalty for the owner. Antwerp-headquartered underwater ship repair specialist Hydrex, however, repaired the leaky seal allowing the vessel to continue without disruption to its schedule.

Underwater Inspections a Boon - Hydrex

Building upon conventional technical skills and know-how while also taking advantage of the latest technology, Hydrex offers a unique hull monitoring service to its customers. This gives shipowners total control of their ship's hull condition and consequently its performance, with only a minimum of work on their part. Underwater inspections represent a small investment and, if properly done, have the potential to save an owner a great deal of money. * Problems with the propeller such as bent or damaged blades (which can put undue strain on bearings), roughness due to fouling, cavitation damage or bad polishing which can reduce the propeller’s efficiency.

MN100: Hydrex

Hydrex offers turnkey underwater repair solutions to shipowners wherever and whenever they are needed. Hydrex’s multidisciplinary team will help you find the best solution for any problem encountered with your ship below the water line. Hydrex provides a complete range of high quality underwater repair and maintenance services. These are performed on-site to avoid costly unscheduled off-hire time or a drydock visit. The firm immediately mobilizes its diver/technicians to any location around the globe to carry out necessary repair work without the need to drydock.

Quick Propeller Repair Prevents Drydocking

Recently a team of Hydrex diver/technicians performed a propeller blade cropping on a 190-meter container bulker berthed in Hamburg. Two parts of the tip of one of the four propeller blades were damaged and needed to be cropped to restore the propeller’s efficiency. Having developed different procedures for different kinds of damage, Hydrex teams are equipped and trained to make the best out of a bent or broken propeller. Ideally, the in-house developed cold straightening technique is used.

Ecospeed Demonstrator Vessel on Display

Shipowners, shipbuilders and representatives from the Green Award Foundation attended the first in a series of planned ‘roadshows’ Subsea Industries has initiated to demonstrate the zero environmental impact and simplicity of cleaning hulls protected with its Ecospeed hard coating. Taking place last week in Maassluis, just outside Rotterdam, guests boarded Subsea Industries’ maintenance and dive support vessel to watch how vessels coated with Ecospeed can be cleaned effortlessly and legally in harbours…

Hydrex Opens Office in Rotterdam

Hydrex has opened a new office in Rotterdam on March 1. Its purpose is to improve the delivery of services and underwater expertise to the maritime industry of Rotterdam, the company said. To enable a fast mobilization throughout the entire Rotterdam port without delaying a ship’s commercials operations, Hydrex dive support vessels will be stationed in Rotterdam. These workboats are fully equipped with hydraulic cranes, winches, a dive spread and control room. This allows Hydrex…

Complex Steel and Cofferdam Repairs Carried Out Afloat

Hydrex has an in-house Research & Development department that can take care of the engineering aspects of an operation. In this way turnkey solutions can be offered for complex hull and other repairs that require the construction of specific equipment. All the projects are engineered and carried out in close cooperation with the customer and any third party suppliers. R&D evaluates the feasibility of an underwater repair, continue through design and construction of customized equipment and go all the way through to successful execution of the repair or replacement and subsequent follow-up.

UK Navy’s Ice Patrol Ship Gets a New Coating

U.K. Royal Navy Ice Patrol Ship HMS Protector is deployed on operations for 330 days a year, mostly in the Antarctic region, making it essential that her underwater hull is protected against the harsh icy conditions she faces. At the end of May, HMS Protector was coated with Ecospeed at the A&P Tyne Ltd. Shipyard in Tyne and Wear, U.K. A top consideration in a hull coating for ice-going vessels and icebreakers is the ability of the coating to protect the hull in the harshest marine environment there is…