Luxury Yachts: Design Takes a New Track

Simutech Solution Corp. uses realistic simulation to craft a better boat

While it’s widely recognized that HTC smartphones, Garmin GPS devices and a sweeping array of big-brand laptops are staples of the Made in Taiwan effort, it’s a lesser-known fact that luxury yachts (those measuring 80 - 120 ft. are a booming business in Taiwan.

Producing high-quality boats at comparatively low prices, Taiwan’s luxury yacht industry reached a peak in 1987, exporting 1,755 vessels for an export value of more than $190m. However, rising labor costs and the appreciation of the Taiwanese dollar took its toll over the years, and the industry had to weather its share of storms.

However, Taiwan’s luxury yacht sector is back on course, with the country surpassing Germany as the sixth largest yacht maker last year, according to yachting magazine ShowBoats International.

With an E-Composites report pegging growth for the global recreational yacht market at an annual rate of 7% between 2005 and 2012, the Taiwanese luxury yacht sector has been looking to shore up its position and head off international competition from traditional sources, as well as Chineses. To do so, the country’s Economic Planning and Development committee has identified luxury yacht production as an emerging core industry and a variety of efforts are underway to advance growth in this area.

One such plan is the construction of a dedicated yacht-building precinct as part of the Kaohsiung Port City Reconstruction project. On the technology and manufacturing front, industry players are promoting the use of computer-aided engineering (CAE) and advanced simulation to foster innovation among Taiwanese yacht makers while helping them decrease overall cycle times.

“While many yacht companies, shipyards and naval architects have adopted DassaultSystemes’ CATIA application in the last three years, the value of numerical simulation and the concept of digital design evaluation are still not broadly promoted in Taiwan,” said Ray Tsai, technical director of Simutech Solution Corp., which provides consulting services for DassaultSystèmes’ SIMULIA application. “Lots of yacht companies don’t know there is a powerful tool that could immensely improve their design with shorter cycles and better systems integration.”

Employing a Total Design Package

Tsai, together with colleagues Rey-Yie Fong of Tiny Machine and Mechanics Laboratory, and Chia-Chuan O and Yu-Chieh Lin, both deputy engineers with the Ship and Ocean Industries R&D Center in Taipei, have mapped out a route intended to demonstrate just what’s possible with SIMULIA’s realistic simulation toolkit. Discussions with Taiwanese yacht manufacturers revealed a glaring hole in the development process: Most of them outsource the upfront design of their boats to foreign partners. “Often they don’t have the tools or the expertise to design a structure from scratch, let alone optimize a hull structure with composite layouts, or even modify subsequent concepts to increase performance,” said Tsai.

With mounting global competition around styling and price, it makes sense that Taiwanese yacht makers could command a greater edge by bringing more of the design process in-house. Manufacturers are increasingly under the gun to respond to customers’ demands as quickly as possible while still keeping costs low. They also need to strike that proverbial balance between aesthetically pleasing style and delivering a range of competitive onboard features and performance. Technical challenges in the areas of design proficiency, manufacturing cost and quality control have long been barriers for Taiwanese companies looking to maintain their competitive strength against rivals.

Simulation technology provides yacht makers with a deeper understanding of their designs from the start, allowing them to iterate incrementally far earlier in the cycle while also tracing problems during every stage of the development process. “We wanted to help them move iterating cycles from the manufacturing stage to the design stage so that the performance criteria could be evaluated earlier when it costs less to modify,” Tsai said.

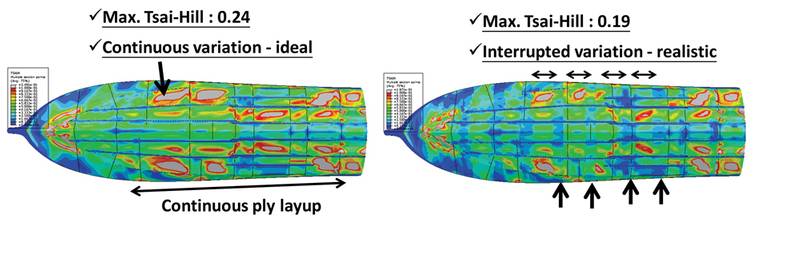

To showcase the powers of digital simulation, Fong chose three critical elements of yacht design that were universally creating challenges for Taiwanese manufacturers: Composite structure layup, ventilation and thermal analysis, and wave impact transient analysis.

“These three areas were most frequently encountered by designers, manufacturers, and customers,” Tsai said. “They were struggling with how to achieve the optimal intrinsic strength and stiffness in their designs along with cabin ventilation efficiency and navigating the tradeoffs around static structure performance and dynamic wave slamming impact. Sometimes the key to orchestrating a design leap is there, but hiding within another configuration. What we wanted to do is to dig it out with different examinations.”

The partners set out to prove their case, taking advantage of the extensive SIMULIA application portfolio based on Abaqus finite element analysis (FEA). Abaqus/Standard, together with Simulayt, was tapped for composite structure layup analysis and manufacturing process management; Abaqus CFD (computation fluid dynamics) came into play for ventilation and thermal analysis; and Abaqus/Explicit was used for Coupled Eulerian-Lagrangian (CEL) analysis, which is central to slamming wave impact simulation.

Having an integrated interface between the CAD tool—in this case, DassaultSystèmes’ CATIA—and the different CAE functions that leverage Abaqus and Simulayt is critical, Tsai said, so users don’t have to change tools or deal with cumbersome data import procedures.

“The concept of integrating structural analysis within the design process benefits complex design projects immensely,” he said. “We are able to import geometry from CATIA and use Simulayt with the composite modeler for Abaqus [CMA] to analyze composite layups. We were also able to reuse the same models for CFD simulation, and material properties and conditions could be shared between models without duplication.”

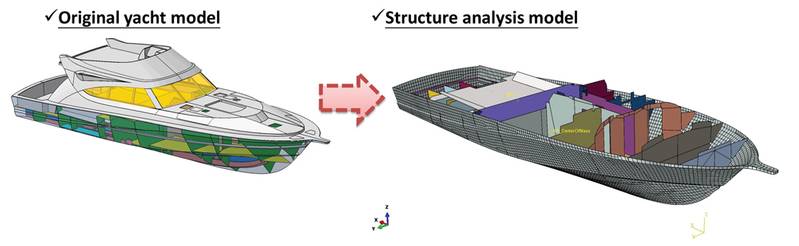

Fong chose a 70-ft. Monte Carlo Yacht to serve as a benchmark for the simulations since it is the median size for Taiwan’s yacht industry and because the specifications of the model mapped pretty closely to the proprietary specifications of most manufacturers.

Modeling Strategies Set Sail with Composites

Applying simulation to the modeling and manufacture of structures made from fiber-reinforced materials is one of the areas where computer-aided engineering (CAE) in luxury yacht design can shine. With all eyes on fuel efficiency and performance, use of composite materials is exploding in the aerospace and automotive sectors, in part because of strict sensitivity to weight demands. While yacht design shares many of the same engineering techniques as the two other sectors, for example, numerical methods, materials selection, system integration and multi-body mechanics—in Taiwan the concept of lightweight structure design is far less mature.

Abaqus CMA provides flexible modeling strategies for quick evaluation of geometry and meshing at both the preliminary and final design stages. With its precise geometry definition, CATIA Composites comes into play at the detailed design stage, helping to optimize design for manufacturability. CATIA generates the composite layup patterns, which can then be assigned to Abaqus with specified material properties and fiber orientation. An interface connects CATIA Composite and Abaqus CMA with automatic data transfer, eliminating the possibility of typos and tedious property assignments layer by layer.

The Simulayt tool helps designers and engineers simulate the forces on a composite structure during manufacturing, rounding out the analysis by predicting plant-floor issues that can be mitigated earlier in the development cycle and helping to meet production timeframes within budget.

Channeling the Sea Breezes

Tsai’s team also applied simulation tools to the design challenge around yacht ventilation. The goal of the exercise was to understand the conduction-convection heat transfer phenomenon, allowing an engineering team to zero in on the optimal ventilation system specification and vent arrangement that would minimize the compressor requirement.

“The challenge is to decide how to arrange the inlet and outlet vents to provide a uniform cooling status in all the cabins,” Lin and O said. Passive vents use a convection effort to circulate air and they work well on nice breezy days, but on hot, still days, they are not as effective.

Active vents include a powered fan and apply a conduction effect. “We set a target that we wanted to unify the temperature distribution and utilize the convection effect to transfer cool air from the upper deck to the lower deck as much as possible,” Lin said. “The CFD visualizations presented a clear image of the air flow along the cabins so we could come up with a concept to improve the arrangement of the vents and design a more comfortable yacht.”

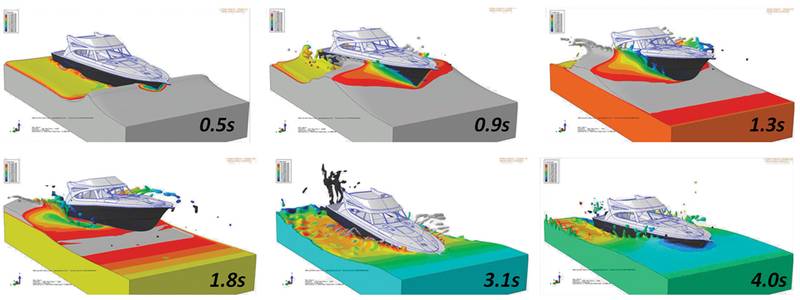

Ensuring Hull Integrity in Rough Seas

The third area where simulation was applied was evaluating the performance of a yacht design under impact from waves, or other scenarios that might test its buoyancy and maneuverability. “Planning a motor yacht or high speed cruiser design needs to take into account the dynamic lifting effect, which implies that the center of buoyancy and center of floating will change with increasing speed,” Fong said. “The subtle balance between center of gravity, center of buoyancy, and center of floating is crucial. It’s tricky to keep the yacht in an evenly keeled condition with a traditional approach.”

Using Abaqus CEL, the team was able to simulate the yacht design’s transient and non-linear varying response to wave impact conditions as well as different turning maneuvers. Reaction force, reaction moment, displacement, velocity and acceleration are recorded on the mass center of the yacht to examine the dynamic performance over time. Slamming contact pressure on the hull is also output to determine the structure loading under transient impact.

More widespread use of these advanced simulation methodologies will help Taiwanese yacht makers have a better chance of sailing past the competition, Tsai feels. “Simulation can help them innovate designs faster while keeping costs in check,” he said.

“To build a faster, lighter, and more luxurious yacht is a challenge, trying to find that compromise between different design considerations. We believe Taiwanese yacht makers will be more competitive in the global market if they are capable of handling more of the design by themselves.”

(As published in the April 2014 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)