Maersk Supply Service Names Karstensen CEO

Steen S. Karstensen has been appointed CEO of Maersk's offshore services arm, Maersk Supply Service, with effect from October 24. Karstensen comes from a position as Chief Procurement Officer and takes over from Jørn Madsen, who was recently appointed CEO of Maersk Drilling, effective November 7. Karstensen joined the Maersk Group in 1986 and has had led a 30-year-career with the company in procurement, logistics, supply chain, in-house consultancy and other cross-functional areas.

Maritime Future Summit: Digital Shipping

Autonomous ships, smart on-board systems: At the Maritime Future Summit on September 5, industry leaders will discuss the future of shipping. For the first time SMM hosts a conference dedicated to digital shipping. Cyber Ships: What may sound like a word from a science fiction novel to some is a hot topic in the maritime business world today. Low-crew and no-crew concepts are buzzwords in the shipping sector, and some initial trials with unmanned ships are already being undertaken. “Visionary ideas drive the evolution of humanity, and the maritime industry is no exception.

CIMAC Announces its New Board

A new CIMAC Board is due to come into force at the completion of the CIMAC World Congress in Helsinki in June 2016 for the customary three-year tenure, 2016-2019. The new CIMAC Board will have Klaus Heim, Chief Technical Officer of OMT S.p.A as the new CIMAC President. Ilari Kallio, Vice President Research & Development, Wärtsilä is also new to the CIMAC Board where he will be taking up the role of Vice President Technical Program along with Marko Dekena, Executive Vice President, AVL LIST, who will continue in his role also as Vice President Technical Programme. Jin Donghan, President of Shanghai University will be the new Vice President for the Working Groups along with Christian Poensgen…

EfficienSea2 Rolls out Maritime Cloud

The Danish-led e-navigation project, EfficienSea2, got one step closer to being launched when a core element of the project – Maritime Cloud – was debated by a group of international maritime organisations and companies. The purpose of the project EfficienSea2 is to develop and implement e-navigation and, thus, up-to-date technology on board ships by introducing and using modern communication, navigation and administrative systems. The concept behind the Maritime Cloud has been developed by the Danish Maritime Authority in connection with previous international projects. By now, it has matured so much that it is ready to receive feedback from relevant international maritime organisations and companies.

Emission Control to Cost Additional $100 bln for Shipping Lines

The implementation of a global sulfur cap slated for 2020 is estimated to add an additional $50-100 billion to the shipping industry's annual fuel bills, Lloyd's List reports. The spread between heavy fuel oil (HFO) and Emission Control Area (ECA) compliant marine gas oil (MGO) is expected to remain in the range of $250 and $400 per tonne, regardless of different price fluctuations, says Niels Bjorn Mortensen, head of regulatory affairs, Maersk Maritime Technology. The estimate could change depending on the future price of blended products like hybrid fuels and whether scrubbers become more common, he added. An updated global cap is expected to limit sulfur content in marine fuel to 0.5 percent from the current 3.5 percent from 2020…

The Ballast Water Management Conundrum

U.S. Ten years on, there’s little certain about ballast water management regulations that the industry can chart a course around other than that it will be expensive – possibly the most costly marine retrofit to date. With install estimates running from $500,000 to as much as $5 million per vessel, across some 68,000 commercial ships estimated by the IMO to transfer 7 billion tons of ballast water annually – industry players say we could be looking at as much as an $80 billion market. Eventually, that is, because there is not a lot of activity right now.

World’s Largest Containership First Tested at MARIN

MARIN was delighted to take part in a truly historic milestone in the industry when Daewoo Shipbuilding and Marine Engineering (DSME) asked MARIN to investigate the seakeeping ability of what would become the largest container vessel in the world - Maersk Line’s Triple-E. MARIN carried out an extensive scope of work, combining numerical predictions and basin model tests to provide the most complete qualification of the vessel’s behavior in various sea conditions. An important yet unfortunately…

Aiming to Make Less Fuel Go Further: Maersk Drilling

Maersk Drilling says it is engaged in an energy efficiency project for its newbuilds together with Maersk Maritime Technology. The project involves an Energy Management System (MSPS), which uses KWH meters and/or data from the Power Management Switchboard to capture real time consumption on-board. Because of the high costs, a small reduction in fuel consumption has a large value. It is costly to sail 14,183 nm from Pusan in South Korea to Curacao in the Caribbean Sea and the bill is paid by its customers and the environment, says Maersk Drilling. 5,206 mt of fuel is used during the voyage, which means an expenditure of US$ 4.7-million for the customer and 16,346 mt of CO2 emitted to the atmosphere.

Maersk, UltraAqua Divest DESMI Stakes

The partners behind DESMI Ocean Guard A/S today announced that A.P. Moller - Maersk A/S and UltraAqua A/S have sold their shares in DESMI Ocean Guard A/S to DESMI A/S. The transaction gives DESMI A/S full ownership of the company, which presently has two Ballast Water Treatment systems in its portfolio. The newly developed RayClean system was launched recently but has already now secured several orders with the first systems being currently under installation. DESMI Ocean Guard A/S was established by A.P. Moller – Maersk A/S, DESMI A/S and UltraAqua A/S in 2009.

Trident Alliance on Track for launch

Trident Alliance, the shipping industry initiative for enforcement of maritime sulphur regulations, is on track for launch after its exploratory meeting in Copenhagen last week. At a full-day meeting on May 28, hosted by Maersk Maritime Technology and Wallenius Wilhelmsen Logistics (WWL) in Copenhagen, representatives from a dozen shipping companies, including some of the world’s largest, negotiated the basis for the new Trident Alliance. At the meeting, the companies agreed that the Trident Alliance will be a coalition of shipping owners and operators who share a common interest in robust enforcement of maritime sulphur regulation and are willing to collaborate to help bring it about.

Alfa Laval Opens Test & Training Center

After months of preparation, the doors of the Alfa Laval Test & Training Center in Aalborg, Denmark are open. Located on the site of the former Aalborg shipyard, this massive ship simulation facility – the largest and most advanced in the marine industry – now adds considerable muscle to Alfa Laval’s research and development efforts. The Alfa Laval Test & Training Center comprises a 250 m2 testing area, built around a 2 MW marine engine and comprising commercial and prototype equipment from all of Alfa Laval’s marine product groups.

Alfa Laval Opens Test & Training Center

Marine R&D enters a bold new era as operations begin at the Alfa Laval Test & Training Center. After months of intense preparation, the doors of the Alfa Laval Test & Training Center in Aalborg, Denmark are open. Located on the site of the former Aalborg shipyard, this massive ship simulation facility – the largest and most advanced in the marine industry – now adds considerable muscle to Alfa Laval’s research and development efforts. The Alfa Laval Test & Training Center comprises a 250 m2 testing area…

First Triple-E named Mærsk Mc-Kinney Møller

Maersk Line’s newest vessel, the first of the Triple-E series, was named this morning in a ceremony at the Daewoo Shipbuilding & Marine Engineering (DSME) shipyard in Okpo, South Korea. It bears the name of the late Mærsk Mc-Kinney Møller, who passed away in April 2012 at the age of 98. Maersk Line CEO, Søren Skou, began the ceremony by welcoming all the special guests and recounting the important tradition of naming ceremonies in Maersk ever since the first event in 1906 welcomed Peter Mærsk as the second vessel in the fleet.

Maersk Tanker Fleet on Fuel-saving Retrofit Crusade

Maersk Tankers plan to spend up to $35m as it pushes ahead with a fuel saving retrofit programme. One of the company's "I-class" VLCCs is being fitted with fuel saving devices, iincluding Becker Mewis propeller ducts and propeller boss cap fins on a range of owned tankers. The programme includes screening and retrofitting around 70 tankers over the next two to three years, reports Carbon Positive. The company's drive to raise fuel efficiency will focus on as many as 35 separate measures, which will all potentially contribute to fuel savings across the fleet.

China Supplies Maersk Triple-E Hull Modules

Hull modules for the huge container ships are being built in Shandong and delivered by barge to South Korea' Daewoo Shipbuiding yard. Twenty of the ships, which can each carry 18,270 20-foot containers and at 399.25 metres long, are being built for Maersk Line by South Korea's Daewoo Shipbuilding & Marine Engineering, reports the 'South Chilna Morning Post', which cites Peter Bertelsen, lead hull superintendent at Maersk Maritime Technology, as informing that a lack of capacity…

DESMI Containerized BWTS Tested by Maersk

DESMI Ocean Guard’s containerised BWTS solution successfully tested by A.P. Moller - Maersk. The OxyClean system based on UV and ozone has come through testing in both fresh, brackish and salt water, and Maersk Line concluded it to be an attractive solution, in particular for container ship retrofits. Per Hother Rasmussen from Maersk Maritime Technology explains: ”We have tested containerized ballast water treatment system plants on two different vessels and we find it a viable…

ABS Forms Operational, Environmental Performance Team

Top talent to take leadership role in developing solutions for industry’s most pressing challenges. ABS, a provider of global classification services, has taken another step forward to meet industry needs with the formation of an Operational and Environmental Performance department. This hand-picked leadership team brings more than 120 years of collective experience to the table to take on the critical industry issues of operational performance, energy efficiency and environmental compliance. “The shipping industry continues to deal with a weak and challenging market. Vessels and assets have to be designed and operated to achieve optimal performance throughout their entire life cycle,” says ABS President and CEO Christopher J. Wiernicki.

Maersk Ships to Have 'Nose Job'

Maersk Line to cut off some container ship bulbous bows as part of initiatives already implemented across its fleet to reduce fuel costs. Research carried out by Maersk Maritime Technology found that the bulbous hull form – initially developed to even out the waves created alongside the vessel and thus reduce the power requirement – is incongruent with initiatives to improve energy efficiency. Writing in the Maersk Post, The Danish shipowner says it can shave up to 2% off the bunker bill by replacing the bulb with a new design. However, because retrofits will be both costly and time-consuming, individual business cases will have to be developed for each class of containership. These changes are being made at China’s Qingdao Beihai Shipbuilding Heavy Industry.

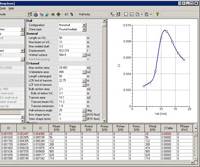

NavCad 2011 Has New Features

New features for the industry-standard resistance and propulsion software. HydroComp NavCad is a software tool for the prediction and analysis of vessel speed and power performance. It also provides for the selection of suitable propulsion system components – engines, gears and propellers. HydroComp has been working since late 2009 on the development of a new architecture for NavCad, and improvements to the interface. This new platform was developed with an eye to the future, and will provide a new structure for future development.

BELCO and A.P. Moller - Maersk Ink Exhaust Gas Cleaning Contract

Demonstration Aboard the Maersk Taurus Containership. Belco Technologies Corporation (BELCO), a wholly owned subsidiary of DuPont, headquartered in Parsippany, N.J., USA, has reached an agreement with A.P. Moller – Maersk, headquartered in Copenhagen, Denmark, to design, manufacture and supply the BELCO advanced marine scrubbing system for demonstration on one of the auxiliary engines aboard the Maersk Taurus. The system will be designed to remain on board as a commercial installation following the successful demonstration. The BELCO Exhaust Gas Cleaning System can be used to reduce SO2 from ship engines and boilers as an economic alternative to using a more expensive low sulphur content fuel when operating in SO2 restricted areas known as emission control area (ECA) zones.

Maersk and U.S. Navy Collaborate on Biofuels

Maersk and the U.S. Navy collaborate on biofuel initiative. Maersk and the U.S. Navy are testing algae-based biofuel on the container ship Maersk Kalmar. The ship is en route from Northern Europe to India. Maersk Kalmar has two key attributes that make it a suitable vessel for biofuel testing. The 300 meter-long container ship has a dedicated auxiliary test engine, which reduces the risks of testing, and its fuels system has a special biofuel blending equipment and separate tanks.

Maersk Ships Save US$ 90-million on Energy Using KPI

In three years Maersk Line says it has saved almost USD 90 million in energy costs by measuring the performance of individual vessels, thus raising awareness on consumption. Other business units are to follow suit. Maersk KPIs, Key Performance Indicators, have for years been a way of measuring how well one did in the past year. Since 2009 however, KPIs have also made their way on to the vessels in a mission to boost performance. The vessel KPIs have evolved in a close dialogue between the vessels…

Maersk, Lloyd’s Register Test Bio-Fuels

Lloyd's Register is to play a major role in a two year program to test the suitability of bio-diesel for use in powering marine engines The feasibility study will take place on board the Maersk Line container ship, Maersk Kalmar. Collaborators in the biodiesel project are Maersk Line, Maersk Tankers, Maersk Supply Service, Maersk Drilling, Maersk Ship Management, Lloyd’s Register’s Strategic Research Group, and a consortium of Dutch subcontractors. The project is being part funded by the Dutch government and co-ordinated by Maersk Maritime Technology (MSM). The bio diesel FAME (fatty acid methyl esters) used for the test will be based on sustainable crops grown in (temperate) regions or reused oils.