Nippon Paint Marine Launches New Antifouling

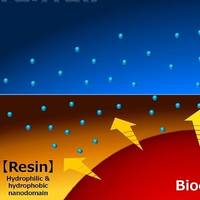

Coatings manufacturer Nippon Paint Marine has launched a new antifouling technology engineered to enhance antifouling performance while improving the time and the film thickness required for application.Introduced to the market this week, FASTAR is a self-polishing antifouling paint that incorporates a unique nano-domain resin structure designed to minimize the effect that seawater temperatures, vessel speeds and other external factors have on coating performance.It is by precisely…

UV-C Keeping Ship Hulls Free from Biofouling

The presence of biofouling on the hull of a ship increases the drag from the water during sailing and thereby the fuel consumption, which results in increased CO2 emissions as well as increased costs for the ship owner. Paints applied to the underwater areas on the hull of ships therefore often contain biocides to hinder biofouling growth or possess non-stick properties, allowing a release of the fouling when the vessels pick up speed.AkzoNobel is working with Royal Philips to…

I-Tech AB Becomes Clean Shipping Index Member

The developer of the barnacle-repelling antifouling ingredient Selektope have become members of the non-profit organization Clean Shipping Index (CSI). Through its membership, I-Tech AB will encourage environmentally responsible decisions around antifouling coating procurement to users of CSI’s holistic labeling system which ranks the environmental performance of ships. I-Tech will seek to promote the benefits of choosing less environmentally impactful antifoulings and educate CSI users on the impact of coating types…

I-Tech AB Signs Deal For Largest Ever Selektope Order

I-Tech AB, the Swedish developer of the bio-repellent antifouling ingredient Selektope, has signed a supply agreement with a Japanese paint manufacturer representing the largest ever single order of the technology to-date. The large volume order was placed by Japanese paint manufacturer Chugoku Marine Paints (CMP) as part of a long-term supply agreement between I-Tech and CMP to support the growth of CMP’s Selektope-containing antifouling product portfolio. The supply agreement…

Selektope Antifouling in demand at Korean Shipyards

As global water temperatures increase, global ‘biofouling hotspots’ in subtropical/tropical areas are intensifying, exposing newbuildings at the world’s major shipyards to greater risk of hard fouling during the outfitting process. The effects of intense hard fouling on idle newbuilds can have great impact on a newly applied hull coating and on a vessel’s performance in sea trials. In response to this problem, a new antifouling coating specifically targeting hard biofouling prevention during the outfitting period was brought to market by Danish marine coatings specialist Hempel in late 2017. GLOBIC 9500S includes the unique antifouling…

Marine Coatings Evolve for the Better

Innovation and new technology continue to shape the marine coatings market. A narrowing field of global coatings manufacturers offer new products while improving existing ones to meet customer demand. Ultimately, customer demand, along with environmental compliance pressures are all driving the marine coatings industry as ship owners, operators and shipyards alike seek better products. Customer demands are often related to cost and efficiency. Costs – and the list is a long one – include not just product cost…

Hempel’s Fouling Defence Product Hempaguard Applied to 500 Vessels

Leading marine coatings manufacturer, Hempel, announces - after only two and a half years on the market - its award winning innovative fouling defence product Hempaguard has now been applied as a full vessel coating to 500 ships. This milestone was reached yesterday with the coating of a 61,614 dwt, 2011-built, container vessel. Environmental obligations are at the top of the agenda for all responsible shipping companies and Hempaguard was introduced to the shipping industry against a backdrop of rising bunkering costs, tightening environmental regulations and the introduction of mandatory Ship Energy Efficiency Management Plans (SEEMP).

350 Vessels coated with HEMPAGUARD Product

Just two years after its launch, leading manufacturer of marine coatings – Hempel – announces that its revolutionary award winning antifouling product HEMPAGUARD has now been applied as a full vessel coating to more than 350 ships. HEMPAGUARD was launched two years ago during London International Shipping Week 2013 after a five-year development programme, and is Hempel’s first product to use its proprietary ActiGuard® technology that integrates silicone-hydrogel and full diffusion control of biocides in a single coating. So confident is Hempel of its performance that the company offers the industry’s first performance satisfaction guarantee.

Hempel Celebrates 100 Years

Hempel kicked off the group’s centenary celebrations and invited customers from Greece, Bulgaria, Cyprus and Romania to a party in Athens’ Acropolis Museum on Saturday, May 9. Hempel has had a permanent presence in Greece since 1952 as Hempel Hellas General Manager, Keld Laursen explained, “For 63 out of the 100 years we have had our feet on the ground in Piraeus and Athens and we are very proud of this. Hempel’s Group President and CEO Pierre-Yves Jullien expanded, “It is fitting – and a real pleasure - that the first significant centenary event is here in Athens . . .

MSC Reports Better Fuel Efficiency with Jotun's HPS

Jotun Marine Coatings said Mediterranean Shipping Company (MSC) will apply Jotun’s Hull Performance Solutions (HPS) on a number of new and existing vessels. With almost 500 vessels, MSC has one of the world’s largest containership fleets. To help the company reduce bunkering fuel costs and associated CO2 emissions, MSC undertook a program to improve fuel efficiency in 2011. During this period, they worked in close cooperation with Jotun to evaluate hull performance and launch a pilot program to test the impact of antifouling on speed loss.

China Merchant Boosts Efficiency of VLCCs with Jotun HP

China Merchant Energy Shipping Co., Ltd (CMES) will upgrade the antifouling solution on their VLCCs New Builds at Dalian Shipbuilding Industry Co., Ltd. (DSIC) and new subsequent contracts to Jotun Hull Performance Solution (HPS) including SeaQuantum X200. In today’s highly competitive market, facing challenge of environment protection and economic environment, most ship owners are paying more attention to improve efficiency and reduce cost. “We actively respond to the call of energy-saving and emission reduction. According to the characteristics of our fleet, we closely track and adopt international advanced new energy saving and emission reduction technology, continue to promote the technological transformation of energy-saving and emission reduction,” said CMES Assistant president Mr.

I-Tech’s Selektope Approved in China

I-Tech informed that Selektope, a marine biocide used to improve ship hull performance and reduce maintenance, has been approved for use in China. Selektope has been approved for use as an antifouling biocide by the Ministry of Environmental Protection of the People’s Republic of China. “We are pleased to receive approval from the Chinese authorities of our antifouling technology following a rigorous environmental risk assessment,” said Philip Chaabane, Managing Director of I-Tech. Selektope has already been approved in Japan and South Korea and is under registration in the EU.

Maersk Triple-E Ships Upgrade with Hull Performance Solutions

Jotun, the global leader in marine antifouling coatings, has signed a landmark agreement with Maersk Line to supply Hull Performance Solutions with SeaQuantumX200 for the Triple-E new build project. The Triple-Es are the world’s largest ships - renowned as much for their energy efficiency as their size. By upgrading to HPS with Jotun’s top-of-the-line SeaQuantum X200 antifouling coating, the Triple-E ships are expected to reinforce their energy efficiency advantage. Maersk Line has ordered a series of 20 Triple-E vessels, with 10 now already in or entering service, and a further 10 under construction at DSME in South Korea. The vessel is 400m long, 59 meters wide and 73 meters high, boasting a world-beating 18,000 TEU capacity. It weighs in at 165,000 dwt.

Jotun Changes Over to TBT Free Antifoulings

Jotun Paints confirmed the October 10, 2001 announcement on phasing out of antifouling paints containing organotin compounds. The move comes in preparation for the IMO’s ban on the application of paints containing organotin biocides, which will go into effect January 1, 2003. From that date, the complete Jotun Paints antifouling range will comply with IMO’s requirements. According to Jotun, their antifouling technology will maintain performance equal to existing TBT products and will continue to meet expectations. Jotun Paints is gearing manufacture and supply of antifouling paints over the rest of this year to make the transition to the TBT free era as smooth and hassle free as possible, while avoiding the problem of surplus TBT products in 2003.