Alfa Laval Debuts Biofuel-ready Separator

Biofuels are a current and accessible fuel option that can help maritime decarbonize, and Alfa Laval becomes the first to offer biofuel-optimized separators and separator upgrades.Biofuels like HVO (hydrotreated vegetable oil) and FAME (fatty acid methyl ester) can be used by diesel engines without major engine modifications. They can be a carbon-neutral alternative if produced from the right biomass, but they must still be cleaned effectively to prevent performance issues and expensive engine wear.

NETSCo Promotes Two Senior Leaders

NETSCo, a naval architecture and marine engineering firm located in Columbia Station, Ohio, has promoted two of its senior employees to new leadership roles. David Hossenlopp, P.E, has been promoted to the position of Chief Naval Architect, and Nick Hunter, P.E. to Senior Naval Architect / Marine Engineer.“David has been with NETSCo since 2013,” said Richard Mueller, CEO/President, “and throughout this time he has very successfully been involved with a large variety of projects…

MAN Marine Engines Approved for Renewable Diesel

MAN Engines said it has approved all marine engines from its current product range for use with renewable diesel fuel in line with the standard EN15940 in Europe and the US-American specification ASTM D975 of the American Society for Testing and Materials (ASTM) with immediate effect. This will allow customers to replace conventional petroleum-based diesel fuel with "green" or renewable diesel fuel. Renewable diesel fuel is obtained from waste and residues of animal and plant origin…

3D Printed Parts Installed On Oil Tanker

Additive manufactured parts have been built, tested and installed on board the U.S.-flagged oil tanker Polar EndeavorTraditionally, parts used in shipbuilding and repair are manufactured via casting or forging techniques. For this project, a consortium consisting of ABS, Sembcorp Marine, 3D Metalforge and ConocoPhillips Polar Tankers Inc. (Polar) aimed to utilize additive manufacturing (AM) to fabricate three types of parts that surpass conventionally manufactured products in terms of quality.

Naval Fuel-related Assets Protected by Coatings and New Robust Standards

The U.S. Navy has many assets other than its seaborn vessels to care for, and recently it adopted new standards to protect those that are fuel-related. Naval Facilities Engineering Command (NAVFAC) contracted with Master Painter Institute (MPI) services to establish product standards for interior carbon-steel fuel pipes, interior welded fuel tanks, exterior steel systems and waterfront steel structures. These new standards, known as the MPI 500 Series Standards, are for use in numerous aspects of work involving specialized Department of Defense (DoD) petroleum…

Tech File: BioBarrier MarineMBR

The BioBarrier MarineMBR series of Type II sewage treatment plant (STP) from marine sewage and water treatment specialist Scienco/FAST is engineered to help meet the increasingly stringent needs of U.S. Coast Guard (USCG) and International Maritime Organization (IMO) water quality standards and is ideal for water reuse applications, its manufacturer says.With its decades-long history providing adaptable and proven marine sewage devices, environmentally-friendly cleaners and other industrial water management technologies…

In the Dock with Selective Electroplating

Surface plating is widely used to repair or salvage critical components in the marine industry. As many components need disassembly, the repair process is typically carried out when the ship is in dry dock. Due to the nature of the plating process, this work is usually performed by plating or machine shops off-site. In a quest to add value through reduced downtime and labor costs, many shipyards are looking to bring this service in-house. Mark Meyer, Sales Manager North America at SIFCO ASC…

NTSB Weighs in on McCain Collision

Insufficient Training, Inadequate Bridge Operating Procedures, Lack of Operational Oversight Led to Fatal Ship Collision. The National Transportation Safety Board said Monday that the Aug. 21, 2017, collision between the USS John S McCain and the tanker Alnic MC was caused by insufficient training, inadequate bridge operating procedures and a lack of operational oversight.Ten sailors aboard the John S McCain died in the accident and 48 were injured when the ships collided in the Middle Channel passage of the Singapore Strait Traffic Separation Scheme.

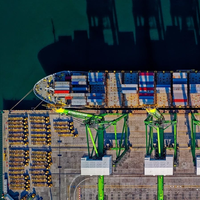

Asian Ports to Use Handheld XRF Analyzer

Port authorities in Asia are getting ready to enforce IMO 2020 with the help of Hitachi High-Tech Analytical Science’s X-MET8000 handheld XRF analyzer.The Hitachi High-Technologies Corporation informed that it has recently delivered X-MET8000’s to both the Maritime and Port Authority of Singapore and the Australian Maritime Safety Authority (AMSA) as they get ready to enforce the IMO’s (International Maritime Organization) MARPOL Annex VI regulation that will come into force on 1 January 2020.The Maritime and Port Authority of Singapore, required a fuel oil sulfur content test kit, awarded Hitachi High-Tech the contract for supply of…

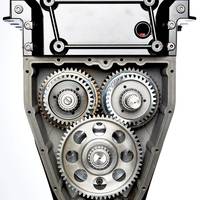

PROPULSION: The OXE Diesel Outboard Arrives

Swedish manufacturer Cimco Marine has developed the world’s first 200hp diesel marine outboard – named the OXE Diesel – for maritime security agencies, yacht tenders, municipalities and military applications.As Trace Laborde, Marine Manager for Laborde Products, said, “The OXE diesel is the complete package, a true diesel engine. It’s great for any maritime application that requires fuel efficiency, simple maintenance, compliance with all European and EPA Tier 3 regulations, and unmatched performance.

Onboard Fuel Compatibility Testing is Growing

Parker Kittiwake is witnessing an increase in demand for onboard fuel compatibility testing.The trend reflects the urgency in the market as shipowners and operators take a more deliberate and proactive approach to mitigating the risks of potential marine fuel oil incompatibility and stability issues associated with the impending 2020 global sulphur cap regulation.With the majority of shipowners expected to opt for very low sulphur fuels of 0.5% or less to achieve compliance, the shipping industry is seeing a rise in new blended fuels appearing on the market.

Shannon Insulation Solutions for Passenger Vessels

Shannon Enterprises of W.N.Y. a designer, and maker of reusable thermal and acoustic insulation, has put in place a custom-designed insulation system for Maid of the Mist Corp.'s two vessels, Maid of the Mist VI and Maid of the Mist VII, to improve engine efficiency, safety and acoustics on board each vessel.As part of a modernization program for the boats' lighting and climate controls, Maid of the Mist's engineering team installed a new generation set - including two, 38 kW Northern Lights marine generators - for both vessels.

MOSI Anti-Fouling Coatings for Barnacles and Zebra Mussels

Marine organisms such as barnacles and zebra mussels have been a long-standing nuisance to ship hulls, causing exterior damage, increased power and fuel consumption and environmental concerns. While anti-fouling coatings help to prevent biofouling, a new research study suggests that an innovative approach to marine coatings may solve the problem of barnacle and zebra mussel fouling, an approach stems from the MOSI (Marine Organism Sensory Interference) concept. MOSI uses a unique coating tech to interfere with the sensory ability of juvenile barnacles…

Wilhelmsen, Hitachi Deliver XRF Analyzers

Signing a supply agreement with Hitachi High-Tech Analytical Science (Hitachi High-Tech), Wilhelmsen will supply Hitachi High-Tech’s industry-leading handheld XRF analyzers to the maritime market, enabling vessel crews to accurately and efficiently test the sulphur content of their fuel, on the spot.With the International Maritime Organization’s 0.50% global sulphur cap on marine fuels set to come into force on January 1, 2020 and discussions on enforcement strategies and potential penalties for non-compliance gathering pace…

Wilhelmsen Ships Service Readying for 2020

The 1st of January 2020, the date when the permissible level of sulphur in fuel is lowered from 3.5% down to 0.5%, is fast approaching.To meet demand, in addition to low sulphur distillates, the fuel market will also include a number of new hybrid and blended fuels.In preparation for 2020 Wilhelmsen Ships Service is recommending owners and operators address the stability and compatibility issues associated with new low sulphur, hybrid, and blended fuels head-on, with their test and treat program.Jonas Östlund, Product Marketing Manager, Oil Solutions, Wilhelmsen Ships Service, believes that regular fuel testing allows crews to gain a better understanding of the fuel quality…

USCG Implements Handheld Technology for Onboard Oil Testing

With a motto of Always Ready, the United States Coast Guard (USCG) has 11 missions specified by law including drug and migrant interdiction; ports, waterways and coastal security; fishery patrols; search and rescue; and national defense. The USCG’s newest ships including 22 Fast Response Cutters (FRCs) recently entered service with 36 more on order and six new National Security Cutters (NSCs) with two more in the process of being built. Oil analysis plays a critical role in the…

Yale Cordage Acquires Largest Test Bed in Eastern US

Yale Cordage announced its acquisition of a Sahm Splice test bed, with capacity for destructive and non-destructive testing of synthetic rope, wire rope, shackles, chain and slings up to 1,300,000 pounds in tensile and a low-range capacity of up to 250,000 pounds. With a maximum test sample length of 116 feet with a 15 foot stroke, it is one of the largest and most capable test beds in the eastern United States.“We are very excited to bring this added test capability to Yale for our existing and future clients,” says Bill Putnam, President of Yale Cordage.

New Oil Spill Tech Solutions Put to the Test

No two oil spill response operations are the same. Each can present new and even tougher challenges for spill responders as they detect, contain and recover spilled oil. Diverse aspects affecting oil spill response operations can be the physical environment, spill monitoring, use of chemical dispersants, and the availability of proper technology for the situation.Some challenges have been met through research and technology development of techniques for dealing with spills. However…

EALs Rise Up on Deck

The next critical area of consideration for the use of Environmentally Acceptable Lubricants is on deck. What’s leaking into the water from your cranes and winches? Vessel fleets face an increasing number of environmentally-focused regulations, adding complexity to their operations and creating urgency around compliance. These regulatory requirements, however, do not offset an operator’s need for products that perform consistently well. With the right Environmentally Acceptable Lubricants (EALs)…

Oil Spill Response: USCG Testing Evolves

Coast Guard R&D Center’s JMTF is a big part of the nation’s environmental research efforts. In 1972, the U.S. Coast Guard Research and Development Center (RDC) established the Fire and Safety Test Detachment (FSTD), which later became the Joint Maritime Test Facility (JMTF), at Coast Guard Sector Mobile in Mobile, Alabama. As part of the unit’s establishment, test facilities were also built on nearby Little Sand Island in Mobile Bay. Since its inception, multiple retired commercial vessels were used as test platforms ending with the State of Maine, which was removed in 2010.

Fuels of the Future

The imposition of a global 0.5% sulfur cap may be less than four years away. This clearly will eliminate residual fuel from the available fuel options unless you have fitted your vessel with a scrubber or other exhaust gas treatment technology in order to comply with MARPOL Annex VI emission regulations. At the start of 2015, permitted sulfur levels in emission control areas (ECA) dropped from 1% m/m to 0.10% m/m. Although this was a large reduction, the switch was relatively…

Why Should I Care About Thermal Insulation?

There are a million important things to worry about on any vessel, so why does high-performance thermal insulation deserve a place on the list? Answer: Because it has a very important role to play in keeping your vessel out on the water, being operated safely by a crew and safely carrying passengers. What is High-performance Thermal Insulation? When we talk about high-performance thermal insulation, we’re talking about insulation that can stop a significant amount of heat, in a relatively small space.

Ohmsett: Advancing Spill Response Every Day

The National Oil Spill Response Research and Renewable Energy Test Facility has been an integral part of the spill response community for more than three and a half decades. Tucked away on the shores of the Sandy Hook Bay in central New Jersey resides Ohmsett – The National Oil Spill Response Research and Renewable Energy Test Facility. It has been an integral part of the spill response community for more than three and a half decades. Government agencies, private industry, and oil spill response organizations from around the world have visited the facility for testing, research and training.