Marine News' Top Vessels of 2022

The November edition of Marine News magazine highlighted the most notable newbuilds delivered in 2022. From sturdy and nimble workboats, to the first new Jones Act laker in a generation, each vessel on display showcases the industry’s engineering prowess and technological ingenuity, with the focus on improving efficiency in operations. The maritime industry has no shortage of challenges to overcome, and each of Marine News’ top vessels will, in one way or another, aid efforts to tackle them.Mark W.

Minten Named Executive VP of Marine Travelift

The Marine Travelift/Shuttlelift/ExacTech, Inc. family of companies announced Kurt Minten has been promoted to Executive Vice President of Marine Travelift. As the longest tenured employee in Marine Travelift history, Minten has many years of experience in all aspects of the business and has held positions in both engineering and sales leading up to this promotion.Minten’s experience with Marine Travelift began even before he was an employee of the company. Early in the company’s history…

Interlake Steamship Christens First New US-flagged Laker in Nearly 40 Years

The Interlake Steamship Company held a christening ceremony in Cleveland on Thursday for its new vessel, Mark W. Barker, the first U.S.-flagged freighter built on the Great lakes in nearly four decades.“This is truly a historic celebration for our company and for the United States maritime industry as we proudly christen the newest vessel to join the U.S. flag fleet on the Great Lakes and our first new build in 41 years,” said Mark W. Barker, President of The Interlake Steamship Company and the vessel’s namesake.

US' First Modern Laker Begins Maiden Voyage

The newly built Mark W. Barker, the United States' first new Great Lakes bulk carrier in nearly 40 years, has embarked on its maiden voyage from Fincantieri Bay Shipbuilding in Sturgeon Bay, Wis.“This is a monumental day for our company and the U.S. flag fleet as our much-anticipated freighter departs on her first voyage in what will be a long life of service on the Great Lakes,” said Mark W. Barker, President of The Interlake Steamship Company and namesake of the vessel—the company’s first new build since 1981.

New US-flagged Laker is First to Be Launched in Nearly 40 Years

A ceremony held at Fincantieri Bay Shipbuilding on Thursday marked the launch of the first U.S.-flagged Great Lakes bulk carrier to be built in nearly four decades. The 639-foot Mark W. Barker, currently under construction for Ohio-based The Interlake Steamship Company, was floated in the large drydock at the Sturgeon Bay, Wis. shipyard.“Today is truly gratifying for our company to commemorate the first time the completed hull of our new ship has touched water,” said Mark W. Barker…

Video: Keel Laid For First New US-flag Laker in Decades

A keel laying ceremony on Tuesday marked the official start of assembly on the first new U.S.-flagged Great Lakes bulk carrier to be built in more than 35 years.During the ceremony held by The Interlake Steamship Company and Fincantieri Bay Shipbuilding, (FBS) the keel was laid within the shipyard’s large graving dock in Sturgeon Bay, Wis. following more than nine months of engineering and prefabrication work of its modular sections by the FBS team.Though the build project is already well underway…

Bay Shipbuilding Cuts Steel on Great Lakes Freighter

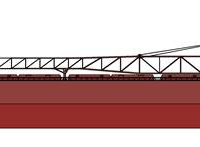

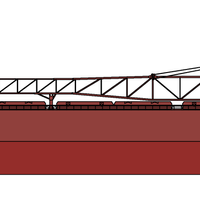

The U.S. Great Lakes freighter fleet are well-renowned for being a 'mature' group of ships, a point magnified yesterday when Fincantieri Bay Shipbuilding started construction on the first U.S.-flagged Great Lakes bulk carrier built in more than 35 years. The shipyard and the owner, The Interlake Steamship Company, hosted a ceremonial first-cut-of-steel event Wednesday, August 14, signalling the start of construction.The new River-Class, self-unloading bulk carrier is believed to be the first ship for U.S. Great Lakes service built on the Great Lakes since 1983.

Interlake Orders Great Lakes Newbuild

U.S. ship owner The Interlake Steamship Company said it has ordered a new U.S.-flagged Great Lakes bulk carrier, the first to be built in more than 35 years. Measuring 639 feet in length (78 feet W, 45 feet H, 28,000 DWT), the vessel will be constructed by Fincantieri Bay Shipbuilding, in Sturgeon Bay, Wis., for scheduled completion in mid-2022.The new River-Class, self-unloading bulk carrier is reportedly the first ship for U.S. Great Lakes service built on the Great Lakes since 1983.The Interlake Steamship Company…

Ship Repair: Fincantieri Bay Shipbuilding Delivers Major Conversion

Fincantieri Bay Shipbuilding has delivered the newly-converted barge Commander to Port City Marine Services (PCMS) of Muskegon, Michigan. The Commander is a 495 x 72-ft. freight barge that underwent extensive conversion, including the installation of new cargo holds, trunk deck and bow, and a new cargo unloading system. Combined with its tug, the vessel operates as an Articulated Tug Barge unit.Port City Marine Services is experienced in the management, conversion and operation…

GREAT WORKBOATS: The Very Best 10 of 2018

MarineNews showcases the ten best of North America’s 2018 workboat deliveries. Domestic shipyard production is robust, innovative and getting greener. And, that translates into two kinds of ‘green.’As the domestic offshore energy support sector slowly awakens, other sectors have been happy to take the spotlight in its absence. As always, and if a hull was delivered in 2018, we took a look at it, with several areas as a focus for inclusion into this edition. For my part, I’m always excited when the U.S. boatbuilding sector can deliver for a foreign buyer. We’ve checked that box here. And, that’s because we can compete on price, quality and when we do…

Marine News Boat of the Month: February 2018

In late November 2017, Great Lakes Dredge & Dock Corporation (GLDD), the largest provider of dredging services in the United States and a major provider of environmental and infrastructure services, took delivery of the new build ATB hopper dredge Ellis Island and tug Douglas B. Mackie after successful completion of United States Coast Guard and ABS regulatory sea trials. Representing a substantial reinvestment in the GLDD (and U.S. flag dredging) fleet, Ellis Island significantly…

GLDD, ESG in Steel Cutting Ceremony

Eastern Shipbuilding is pleased to announce that on, Monday, September 15, 2014, Great Lakes Dredge & Dock Company, LLC “(Great Lakes”) (NASDAQ: GLDD) and Eastern Shipbuilding Group, Inc. (ESG) cut steel starting the construction of a new Trailing Suction Hopper Dredge ATB . The cutting ceremony of the 433’ Trailing Suction Hopper Dredge Barge took place in Eastern’s under roof pre-fabrication building at its Allanton facility in Panama City, Florida. This indoor facility supports both of Eastern’s new construction facilities with state of the art equipment and a highly skilled workforce.

Eastern Shipbuilding Start Construction of Dredge Barge ATB for Great Lakes

Eastern Shipbuilding is pleased to announce that on, Monday, September 15, 2014, Great Lakes Dredge & Dock Company, LLC and Eastern Shipbuilding Group, Inc. (ESG) cut steel starting the construction of a new Trailing Suction Hopper Dredge ATB . The cutting ceremony of the 433’ Trailing Suction Hopper Dredge Barge took place in Eastern’s under roof pre-fabrication building at its Allanton facility in Panama City, Florida. This indoor facility supports both of Eastern’s new construction facilities with state of the art equipment and a highly skilled workforce. • WHEELOBRATOR Automatic Shot-blasting and Painting Machine for steel plate and shapes. • MESSER MG CNC (NC) plasma cutting and burning machine with four (4) 10’x40’ dry cutting tables.

Demand for Coastal and Transoceanic ATBs Grows

Along the way, ATBs gain speed, efficiency, safety – and popularity. Operators of articulated tugs and barges, or ATBs, say they like the maneuverability, weather reliability, stability, speed of these units, and the manner in which the tug pushes the barge. As a marine transportation concept, they can also simply be described as versatile. ATBs move petroleum, chemicals, coal, grain, containerized cargo and rail cars for customers on the U.S. coasts, rivers, the Great Lakes and overseas. As a result, demand for articulated units expanded in the last two decades with new technology.

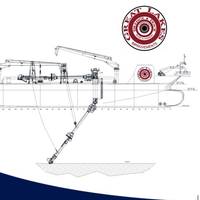

Eastern Shipbuilding Get GLDD Dredger/Tug ATB Contract

Eastern Shipbuilding inform that Great Lakes Dredge & Dock Company, LLC (GLDD) has placed orders for construction of a 433’ Trailing Suction Hopper Dredge Barge and a 158’-4” 15,600 BHP, CPP Tug. Named the GLDD302 (ESG Hull 252), the ATB Tug detailed engineering is being performed by Ship’s Architect, Inc. and the GLDD151 (ESG Hull 253), the ATB Dredge Barge by Bay Engineering, Inc. Both are based upon an Ocean Tug & Barge Engineering, Inc. ATB design. This Trailing Suction Hopper Dredge, Articulated Tug and Barge (ATB) Unit, will be delivered in 2016.

BAE Lays Keel on GLDD Dump Scow

BAE Systems recently held a keel laying ceremony in the construction of the second dump scow for Great Lakes Dredge and Dock Company. It is the final vessel in the contract for two dump scows, which was signed in June 2012. When complete, both vessels will be used to support dredging operations in the United States. Employees and executives from BAE Systems gathered at the foot of the 98 ton keel block as long-time shipyard employee Nick Elmes, an engineer, drove the ceremonial wedge and welded his initials in the keel of the vessel, called Hull 108.

BAE Systems Lays Keel for Dump Scow

BAE Systems has completed another milestone in the construction of the first of two dump scows for Great Lakes Dredge & Dock Company. When complete, both vessels will be used to support dredging operations in the United States. Employees and executives from both companies recently gathered at the foot of the 98 ton keel block as Steve Becker, vice president of Great Lakes Dredge & Dock, drove the ceremonial wedge and welded his initials in the keel of the first vessel, Hull 107.

Signal International Lands Hopper Dredge Deal

Signal International, Inc., has landed a $94 million contract from Great Lakes Dredge & Dock Corporation, (GLDD) to build an Articulated Tug & Barge ("ATB") Trailing Suction Hopper Dredge. The 15,000-cubic-yard-capacity Dual Trailing Arm Suction Hopper Dredge with a 14,000-horsepower tug is believed to be the world’s first fully integrated ATB Dredge and the largest hopper dredge in the United States. The dredge barge dimensions are 410 ft x 92 ft x 36 ft (124.97m x 15.85 x 10.97m) with the tug measuring 150 ft x 52 ft x 36 ft (45.72m x 15.85 x 10.97m).

Great Boats of 2000

Every year, MarineNews chooses a handful of vessels delivered in the past 12 months and bestows upon them the distinction of “Great Boats.” The boats are chosen for innovations in design, construction and utilization. Following are the 17 vessels or groups of vessels chosen as the Great Boats of 2000. Crowley Marine Services delivered Alert, Attentive, and Aware, a series of three 140-ft., 10,000-hp Prevention and Response Tugs (PRTs), to Alyeska Pipeline Service Company in Valdez, Alaska. Specifically designed and developed for Alyeska, the boats will be used by Crowley in the Trans Alaska Pipeline System trade. Alert was deployed in February; Attentive was delivered in June, and Aware was delivered in July.

Great Lakes' Biggest Dual-Mode ITB Begins Service

One of the most labor- and fuel-efficient bulk material carriers on the Great Lakes entered service in June 2000. The self-unloading barge Great Lakes Trader is owned by Great Lakes Marine Leasing, Portland, Ore., and operated by VanEnkevort Tug and Barge, Bark River, Mich. The 740 x 78 ft. (226 x 24 m) Trader is the largest vessel capable of fitting through the St. Lawrence Seaway locks. Combined with the 10,200-bhp (7,600 bkW) tug Joyce L. VanEnkevort, the new integrated tug/barge (ITB) unit is the biggest dual-mode ITB on the Great Lakes. The 39,600 long ton (40,234 metric ton) capacity Trader was designed by a team of engineers directed by naval architect Joe Fischer, president of Bay Engineering, Inc., Sturgeon Bay, Wisc.

Halter to Build 740 Ft. Self-Unloading Bulk Carrier

Halter Marine Group, Inc., Gulfport, Miss. has signed a contract with Great Lakes Marine Leasing, LLC, to build a 740 ft. self-unloading dry bulk cargo barge for service on the Great Lakes. The barge, which will be named Great Lakes Trader, will be operated by Van Enkevort Tug and Barge out of Escanaba, Mich. The barge will be built and launched in two halves at Halter's Gulf Coast Fabrication, Inc. in Pearlington, Miss. and towed to New Orleans where the two halves will be joined in Halter Gulf Repair's large floating drydock. Final outfitting will be completed at Halter Gulf Repair by the owner. At 740 ft. overall length with a 78 ft. beam and 45 ft. depth, it will be the largest vessel ever constructed by Halter. It will be the maximum size permitted through the St.

The ATB : A History of the State-of-the-Art

(This is Part II of a two-part series on the Articulated Tug Barge from Robert P. Hill. Why The ATB? The ATB, or "Articulated Tug/Barge" unit is designed to combine the economics of tugboat and barge operation with the speed and weather-reliability of a ship. A hallmark of this concept that makes it different from the ITB or "Integrated Tug/Barge" is the fact that both the tug and the barge are truly independent vessels able to operate successfully even if not together. The tug is a full ABS or internationally-classed ocean tug, capable of meeting all SOLAS regulations where required. It can be made capable of towing and other traditional tug missions.

SNAME 2009 Medal Award Winners

The Society of Naval Architects and Marine Engineers (SNAME) recognized four individuals for their outstanding contributions to naval architecture and marine engineering. The annual achievement medals were presented at the SNAME Annual Banquet, held during the SNAME 2009 Annual Meeting and Expo in Providence, R.I. The society’s top award, the Vice Admiral "Jerry" Land Medal for outstanding accomplishment in the marine field, was presented to Robert D. Somerville, Chairman and Chief Executive officer of the American Bureau of Shipping (ABS).