Wärtsilä to Equip LNG-fueled RoLo Newbuilds

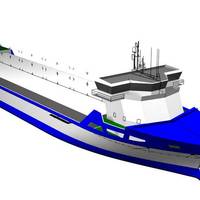

Wärtsilä announced on Friday that it will supply the main equipment for three liquefied natural gas (LNG) fueled short-sea Ro-Lo (roll-on, lift-off) vessels to be operated by Finland based Bore Ltd., an affiliate of the Dutch Spliethoff Group.The ships have been ordered and are being built at the WuHu Shipyard in China. The order with Wärtsilä was placed in December.Wärtsilä said it has worked in close collaboration with both the owner and the naval architect to develop a vessel optimized integrated LNG system.

Conoship to Design DP2- B-type Vessels for Spliethoff

The Netherlands-based maritime engineering company Conoship International recently signed a contract with China’s Mawei Shipyard for the design of Spliethoff’s two multipurpose DP2 B-type vessels.The versatile characteristics of this new B-Type make this vessel unique in the market and will comply with the requirements of IMO Tier III. They are built under class of Lloyd’s Register, have ice class 1A and also comply with the Polar code.The ships are to be delivered in October 2021 en February 2022.Shipping company Spliethoff Group, Amsterdam, has recently ordered nine new ships from Chinese shipyards. For all of which Conoship International has been selected to deliver the design.

UPM to Charter 7 LNG-fueled Newbuilds

Helsinki-headquartered UPM Logistics says that it has entered into a long-term charter agreement with the Finnish Bore Ltd and the Dutch Wijnne Barends, both affiliates of the Dutch Spliethoff Group.Together, the companies will design and build seven state-of-the-art vessels for sustainable sea transportation for UPM in Europe.“This arrangement is a consistent step in UPM’s logistics strategy. It will safeguard a sustainable, competitive and reliable shipping solution for our businesses and customers on long term,” said Lauri Rikala, Director, Global Break Bulk Shipping, UPM Logistics.Bore Ltd will build three (3) RoLo vessels for transporting…

Scrubber Installed Aboard M/V Bore Song

The exhaust gas cleaning system (scrubber) supplied by Deltamarin Floating Construction to Bore Ltd on a turnkey basis, has received confirmation of full compliance with SECA and IMO regulations (approved by Lloyd's register and TRAFI, the Finnish Transport Safety Agency). After the 14-day dry docking, the open loop operation of the scrubber was in immediate use when the ship left the repair yard. The system delivered for the 13,500 DWT RoRo ship M/V Bore Song 12MW main engine (Wärtsilä 12V46F CR 12,000 kW) is based on DeltaLangh scrubber technology.

Norsepower’s Rotor Sail Solution Successfully Tested

Norsepower Oy Ltd. and Bore Ltd today carried out successful sea trial of Norsepower’s Rotor Sail Solution, a new wind propulsion technology for ships. The sea trials, verified by NAPA and supported by VTT Technical Research Centre of Finland, confirm fuel savings of 2.6% using a single small Rotor Sail on a route in the North Sea. With these fuel savings, the technology has a payback period of 4 years. Based on the trials, Norsepower and Bore believe that a full system on Estraden with two rotors has the potential to deliver 5% efficiency savings on an ongoing basis. Norsepower forecasts savings of 20% for vessels with multiple, large rotors traveling in favourable wind routes. The Norsepower Rotor Sail Solution was installed on the 9,700 DWT Ro-Ro carrier MS Estraden.

The Ballast Water Management Conundrum

U.S. Ten years on, there’s little certain about ballast water management regulations that the industry can chart a course around other than that it will be expensive – possibly the most costly marine retrofit to date. With install estimates running from $500,000 to as much as $5 million per vessel, across some 68,000 commercial ships estimated by the IMO to transfer 7 billion tons of ballast water annually – industry players say we could be looking at as much as an $80 billion market. Eventually, that is, because there is not a lot of activity right now.

Sulfur Regulations Spur Fuel-saving Technologies

With many ship owners switching to marine gas oil (MGO) inside designated Emission Control Areas (ECAs) as of January 1, 2015, the cost of fuel could rise by up to 50%, so all measures to reduce fuel consumption are vital. Research and field testing has shown that the latest developments in engine lubrication and unique marine energy management systems can add more than a 15% improvement in fuel efficiency, proving that even the smallest modification at the right time can add up to big savings.

Condition Based Monitoring & Saving Cash

Profitability in shipping goes up and down in waves. 2012 wasn’t too bad, with annual operating costs shrinking by 1.8% on average versus 2011, when average costs rose 2.1%, but 2013 weighed anchor in the losses column for many. And 2014? So far the waters are choppy, with the overall mood up in May but dipping down in the quarter that ended in August, according to Moore Stephen’s quarterly Shipping Confidence Survey. Much of what worries the industry concerns issues over which it has little to no control – oversupply…

Bore and P&O Ferries JV add RoRo Vessel

Bore and P&O Ferries announces today that they have agreed to add a further RoRo vessel to the long-standing partnership in the North Sea. M/V Estraden will be added to the vessel portfolio sailing for P&O alongside M/V Norsky, M/V Norstream and M/V Bore Song. She will move to her new route in January 2015. M/V Estraden is a similar vessel to M/V Norsky and M/V Norstream, which have proven suitable for the P&O cargo trade. Bore has actively progressed towards sustainable shipping, decreasing the environmental footprint of its RoRo shipping. This has been manifested by decisions like installing NAPA Optimization on the vessels for fuel savings, wet scrubber system on M/V Bore Song, wind rotor system on M/V Estraden.

PPG Offers SIGMASHIELD 1200 Coating for Shipping

PPG Industries' protective and marine coatings business is fulfilling growing demand for "ice class" marine coatings for hull protection with SIGMASHIELD® 1200 coating. Developed from research conducted in PPG’s own facilities, SIGMASHIELD 1200 coating delivers exceptional abrasion and impact resistance in ice, combined with very low friction properties. The coating, developed for very high abrasion and impact applications on decks and hulls, combines a top-of-range phenolic epoxy with carefully-selected pigments to provide exceptional performance in icy waters. SIGMASHIELD 1200 coating has already seen more than a decade of service on ships operating in areas of heavy ice formation, including the Baltic Sea and St. Lawrence Seaway/Great Lakes system.

Bore RoRo Ship to Get DeltaLangh Scrubber System

DeltaLangh has been assigned to deliver Deltamarin Floating Construction Ltd. with an exhaust gas cleaning (scrubber) system to be installed onboard the Ro-Ro vessel M/V Bore Song of Bore Ltd. The delivery consists of a combined closed and open loop scrubber system for 12MW engine output with the patented water treatment and dewatering plant. M/V Bore Song operates in the English Channel which is a part of the Sulphur Emission Control Area (SECA). From January 2015 all ships operating in the SECA area must limit their emissions to correspond to the use of fuel with a sulphur content of less than 0.1%. With the help of the DeltaLangh scrubber M/V Bore Song will meet these requirements.

Harnessing the Wind for Auxiliary Propulsion

Finnish marine engineering company Norsepower Oy Ltd. announced that it will bring to the commercial maritime market an auxiliary wind propulsion solution aimed at maximizing cargo ship fuel efficiency, with first sea tests on a Finnish cargo ship slated to begin later this year. Norsepower’s Rotor Sail Solution is an updated version of the Flettner rotor, a concept that dates back to Finnish engineer Sigurd Savonius in the early 1900s. The Flettner rotor gets its name from German engineer Anton Flettner…

Bore, NAPA & ClassNK Team for Energy Consumption Study

Saving energy on fleet operations is a top line concern for every vessel owner, large and small. 110-year-old Finnish shipowner Bore teamed with NAPA and ClassNK to help identify energy waste on not only its ships operating today, but those planned for tomorrow. As global environmental legislative mandates and rapidly escalating fuel prices cumulatively conspire to drive ship owners to find and eliminate energy waste on commercial marine vessels, there has been a plethora of energy saving solutions from all sectors of the industry.

Finland's Bore to Install ClassNK Efficiency Software

Shipping company Bore Ltd. to install ClassNK-NAPA GREEN ship efficiency software aboard their 13,625 dwt Ro-Ro vessel 'M/V Bore Song'. This announcement follows on from sea trials last year aboard sister ship M/V Bore Sea which proved that NAPA operational software had led to a 5.8% reduction in fuel consumption. The ClassNK-NAPA GREEN software system is a joint development between Nippon Kaiji Kyokai (ClassNK), the world’s largest ship classification society, and NAPA, the leading software house for ship design and operations. This collaborative software solution for vessel efficiency, launched in 2012, builds upon the shared expertise…