Damen to Offer ERMA FIRST's Compact oneTANK BWTS

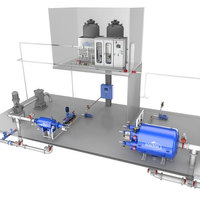

Dutch shipbuilding group Damen has signed its first contact with ballast water treatment systems (BWTS) manufacturer ERMA FIRST. The Greek manufacturer ERMA FIRST will supply its oneTANK, which is the world’s smallest BWTS, using chemical injection methods to clean ships’ ballast water.Damen Green Solutions has a broad selection of BWTS in its range, offering shipowners various capacities and techniques in treating their ballast water. With the addition of the ERMA FIRST oneTANK, Damen can provide clients with a solution that is not only small, but also modular.

USCG Issues BWMS Type Approval, Receives Another Application

The U.S Coast Guard said it issued type approval to one ballast water management system manufacturer this week and added it is reviewing another system after receiving a type approval application from another.The USCG's Marine Safety Center (MSC) issued a Ballast Water Management System Type Approval Certificate to Japanese-based Kuraray Co., Ltd., after a detailed review of the manufacturer’s type approval application determined the system met the requirements of 46 CFR 162.060.The…

Envirocleanse Recieves BWMS USCG Approval

The Marine Safety Center issued the 16th U.S. Coast Guard Ballast Water Management System Type Approval Certificate to Envirocleanse, LLC, after a detailed review of the manufacturer’s type approval application determined the system met the requirements of 46 CFR 162.060.The treatment principle of the inTank BWTS consists of in-tank electrolysis and/or in-tank chemical injection, with in-tank neutralization prior to discharge. This approval covers models with maximum treatment volumes up to 200,000 m3.(Source: Bryant's Maritime Blog)

Coast Guard Approves Another BWTS Entry

Marine Safety Center issues 13th Ballast Water Management System Type Approval certificate.The Marine Safety Center issued the 13th U.S. Coast Guard Ballast Water Management System Type Approval Certificate to JFE Engineering Corporation after a detailed review of the manufacturer’s type approval application determined the system met the requirements of 46 CFR 162.060.The treatment principle of the BallastAce BWMS consists of filtration with chemical injection during uptake and neutralization during discharge.

Ecochlor BWTS Receives DNV GL Type Approval

Ecochlor and DNV GL have announced DNV GL Type Approval on behalf of Norway of the Ecochlor Ballast Water Treatment System (BWTS). In addition to serving as Ecochlor’s Independent Laboratory for US Coast Guard (USCG) Type Approval, DNV GL simultaneously evaluated and approved the Ecochlor System under DNV GL rules and the BWM Convention. With its USCG Type Approval certificate, Ecochlor stands alone as the first approved treatment system produced by a US manufacturer; the only approved chemical injection treatment technology…

Ecochlor BWTS Receives USCG Type Approval

Ecochlor's patented BWTS has received USCG Type Approval. The Ecochlor BWTS uses a two-step process that includes filtration and treatment with chlorine dioxide (ClO2). It is completely effective on all aquatic invasive species regardless of water turbidity, salinity or temperature. “The Ecochlor BWTS works just as effectively as it did when first installed in a ship in 2004 without any fundamental changes," said Tom Perlich, President and Founder. "Since that first system was sold…

DNV GL On Regulatory Developments and Tanker Market

DNV GL’s Tanker Working Group looked at the latest trends in the tanker segment with a special focus on the impact of upcoming emissions regulations at its 31st meeting in Hamburg recently. Some 25 representatives from the tanker industry met with DNV GL experts in the classification society’s maritime headquarters to hear presentations and participate in informal discussions. “The Tanker Working Group is a great place for industry representatives and DNV GL to share ideas and the latest news on regulatory developments, innovations, and the challenges and opportunities for the sector,” said Catrine Vestereng, Business Director Tankers at DNV GL.

DNV GL RP On Thermoplastic Composite Pipes

The oil and gas industry invests billions annually in offshore pipelines and risers. DNV GL has launched a recommended practice (RP) that allows operators to choose thermoplastic composite pipes instead of steel or traditional flexibles, enabling substantial cost reductions throughout the project lifecycle. “Thermoplastic composite pipes are a new, robust lightweight pipe alternative that will impact field layout, and installation methods and ultimately reduce the cost level,” says Per Anker Hassel, project manager with DNV GL – Oil & Gas. DNVGL-RP-F119 Thermoplastic composite pipes (TCP) was developed through a DNV GL-led joint industry project involving 18 companies covering the whole supply chain; from polymer producers, via TCP manufacturers, to oil companies as the end users.

Norvestor to Become PG’s Largest Shareholder

Norvestor VI, L.P., a fund advised by Norvestor Equity AS, announced it has signed an agreement to invest in Ing Per Gjerdrum AS including its subsidiaries PG Hydraulics AS and PG Construction AS. The transaction is expected to close end of October 2014, subject to customary approval from the Norwegian Competition Authorities. Following the acquisition, Norvestor will become the largest shareholder in PG with about 63 % of the shares, while the remaining shares will be held by Mads Gjerdrum and Roy Norum. The company had revenues of NOK 552 million in 2013.

TCO Awarded £75 million Statoil Contract

TCO AS and the daughter company TCO UK, providers of well completion technologies to the global oil and gas industry, have secured a contract with Statoil AS worth an estimated 750 million NOK (75 million GBP). The exclusive contract will require TCO to provide the total scope of chemical injection systems and a framework contract for the scope of B-annulus system and barrier plugs for Statoil operations on the Norwegian continental shelf. The initial contract period is two and a half years with an optional additional period of six years thereafter.

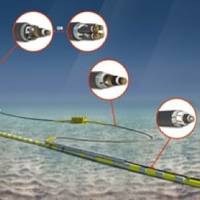

Nexans DEH System in Deep ...

Subsea 7 takes Nexans DEH system deeper than ever before for Chevron’s Lianzi project off SW Africa. The Lianzi development (located in a unitized offshore zone between the Republic of Congo and the Republic of Angola) will include the world’s deepest installation of a Direct Electrical Heating (DEH) system of subsea production pipelines. Nexans say that their field-proven DEH solution provides eco-friendly and cost-effective flow assurance for subsea production pipelines. The contract with Subsea 7 is valued at approximately 25 million Euro…

MOL Installs Ballast Water Treatment System on VLCC

Mitsui O.S.K. Lines, Ltd. announced completion of work to install a ballast water treatment system on the very large crude oil carrier (VLCC) Libra Trader at Keppel Shipyard in Singapore. On January 10, the company announced plans to install the system on a VLCC ahead of IMO installation compulsion. MOL is the first Japanese shipping company to install such a system for existing VLCC. Keppel Shipyard has timely delivered the vessel as committed and Libra Trader has already returned to service, and the ballast water treatment system will be tested and adjusted during operation.

BWTS Fitting on Japanese VLCC a First

Mitsui O.S.K. Lines, Ltd. (MOL) plan to install a ballast water treatment system on an in-service very large crude oil carrier (VLCC). This will be the first such onboard system installed by any Japanese shipowner on an existing VLCC. The company chose the JFE Ballast Ace system developed by JFE Engineering Corporation. The installation will take place while the vessel is docked from March through April. Ballast water discharged while loading/discharging cargo carries marine organisms around the world and can have a negative impact on marine ecosystems and biodiversity.

Decommissioning Guidelines for North Sea Subsea

A new study which aims to inform UK government guidelines on environmentally responsible methods for decommissioning offshore pipeline bundles will be launched in Aberdeen this month. The study was secured with assistance from ITF, the technology facilitator for the global oil and gas industry, following membership support for the project. It will be led by project management and engineering consultancy PDi, with assistance from eight operating companies. Currently, there is no…

Drydocks World Contract for Compact Semi-Sub

Drydocks World has won a contract to build a new state-of-the-art oil well intervention Compact Semi-Submersible (CSS) vessel, representing a third order from integrated energy industries service provider Hallin Marine. The vessel will cost a total of $110m. Designed by STX Canada Marine Inc, the diesel/electric CSS’s primary function is to facilitate repair and maintenance to an existing well, via chemical injection on braided lines, extending perforation tunnels and effectively maximizing and extending the productive life of the well.

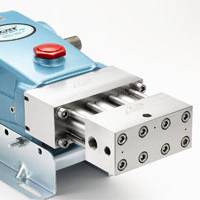

New Positive Displacement Plunger Pump

The new 10,000 PSI Model 1810 pump has been added to Cat Pump’s line of triplex positive displacement pumps. This pump delivers a low pulsation flow of 3 GPM at 10,000 PSI. The 1810 pump has a low unswept volume [minimal un-evacuated liquid remains in the pumping chamber] resulting in high volumetric efficiency. The 1810 triplex positive displacement pump has a compact footprint for both portable and stationary installation. High strength plunger rods, oversized bearings and chrome-moly crankshaft provide a heavy-duty, durable drive-end.

Williams Commissions New Offshore Platform

A unit of Williams has announced that it has commissioned a new production handling platform in federal waters approximately 60 miles south of Mobile Bay, Ala. Gas production from approximately 35,000 acres of federal leases is dedicated to the platform. Construction of Williams' Canyon Station -- a fixed-leg platform in 300 feet of water in East Main Pass Block 261 -- was completed on schedule at the end of June. The jacket was installed in October 2001, followed by the deck and all of the topsides equipment in May 2002. Phil Wright, president and chief executive officer of Williams' energy services unit, said, "The deck is set, the generators are running and we're raring to go.

A&P Tyne Re-Delivers FPSO Haewene Brim

A&P Tyne re-delivered the FPSO Haewene Brim to Holland’s Bluewater following an extensive upgrading to its process plant and hull maintenance period refit. The vessel will now return to the Pierce Field in the U.K. sector of the North Sea under charter to Shell U.K. The contract was won in a partnership between A&P Tyne Limited and McNulty Offshore Contractors Limited of South Shields, who were the prime contractor. The Pierce field is 150 miles due east of Aberdeen in the UKCS (U.K. continental shelf) with a 85 m water depth.

Canyon Offshore Wins Contract on Deepwater Canyon Express

Canyon Offshore has been awarded a one-year Remotely Operated Vehicle services contract to support maintenance on the Canyon Express development in Mississippi Canyon in the Gulf of Mexico. At 7,200 feet of water, Canyon Express is the deepest operating production project in the world and includes three separate gas fields, King’s Peak, Aconcagua and Camden Hills. Under the terms of the contract, Canyon will provide integrated ROV and DP vessel services on an ongoing scheduled and callout basis. Initial planned work includes a detailed baseline CP and visual survey of the East and West flowlines, and the main umbilical and methanol coiled tubing lines. In addition, Canyon will replace subsea chemical injection valves and undertake other field maintenance and intervention tasks as required.

Jurong Secures FPSO Conversion Contracts

Jurong Shipyard, a wholly owned subsidiary of SembCorp Marine, has secured two Floating Production Storage and Offloading (FPSO) conversion contracts worth a total of $58m from Tanker Pacific Offshore Terminals Pte Ltd (Tanker Pacific). The first contract involves the conversion of the 92,802 dwt tanker, the M.T. Andaman Sea, which will be renamed FPSO Raroa upon completion in 4Q 2007. Modification works on the FPSO Raroa will commence immediately involving the installation of an internal turret, 3 boilers on deck to generate 20 megawatts of power, renewal of the entire piping and electrical systems and installation of new process facilities, which include crude separation, water injection and chemical injection.