SUNY Maritime Announces $24.8 Million in Campus Improvements

SUNY Maritime College on Monday announced three major construction projects totaling $24.8 million that will enhance and build on the campus’s state-of-the-art facilities for students pursuing the global marine transportation industry. Ground-breaking and ribbon-cutting ceremonies today with state and local leaders celebrated Maritime College’s new Student Learning Center and its fully renovated Marine Engineering Systems Laboratory, made possible through significant New York…

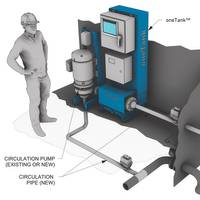

Tech File: oneTank Ballast Water Treatment System

In mid-September, the U.S. Coast Guard Marine Safety Center issued the 35th USCG Ballast Water Management System Type Approval Certificate after a detailed review of Seattle-based manufacturer oneTank, LLC’s type approval application determined its system met the requirements of 46 CFR 162.060.The recent U.S. Coast Guard Certificate of Approval, which follows the DNV GL Certificate of Approval awarded on behalf of the Norwegian Maritime Authority in compliance with the International Maritime Organization BWMS Code in July 2020…

oneTank BWTS Gains US Coast Guard Type Approval

oneTank, LLC has been granted a U.S. Coast Guard Certificate of Approval (162.060/35/0), completing the suite of international approvals required for its ballast water treatment system.The oneTank ballast system is a simple, low-cost treatment option intended for vessels that do not need a complex solution. The system was developed to simplify the installation and treatment of the tanker aftpeak tank, an ideal “one or a few tanks” application. With an arrangement footprint of just two square-feet…

Viega: Maintaining the Flow

Viega Group has a history spanning more than 115 years and today is more than 4,000 employees worldwide, a leading manufacturers of pipe installation technology for shipbuilding, industrial, commercial and residential projects. In the U.S., Viega LLC employs nearly 500 people and offers more than 3,000 products, including Viega ProPress for copper and stainless, Viega MegaPress for black iron pipe and Viega PEX Press systems in Zero Lead bronze and high-performance polymer. While the company serves many markets…

Alfa Laval Sees Greater Interest in High Flow BWTS

With the International Maritime Organization (IMO) Ballast Water Management (BWM) Convention set to take effect in September, Alfa Laval said it has seen growing customer interest in ballast water treatment systems and in its PureBallast. Of particular note is interest in PureBallast systems with high flow capacities. While interest for high flow PureBallast systems has increased, the manufacturer said it is prepared to support vessels with these needs. The IMO and U.S. Coast Guard (USCG) type-approved PureBallast 3.1 features a single-filter solution…

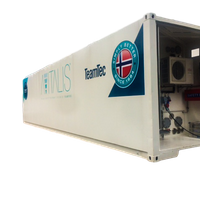

Damen Partners with TeamTec for BWTS

Damen Green Solutions has signed a letter of intent with Norwegian company TeamTec to supply and service the AVITALISTM ballast water treatment system. The system combines filtration and a proven, eco-friendly chemical treatment solution optimized for medium-sized to large vessels. The system is highly effective in water of any salinity, turbidity or temperature. The intention is to advance to a full partnership by the end of 2016. Currently AVITALISTM is undergoing ship board testing IMO type approval and USCG land-based testing.

Intertek Invests $1.8m in Corrosion Test Facility

Intertek has invested $1.8m expanding its center of excellence for corrosion testing services to meet growing demand for asset life extension solutions in the oil and gas industry. The expansion, which has been driven by major new contract awards worth around $1.51m, takes the total investment in the Manchester, UK, site to over $7.55m since it first opened in 2008. Originally consisting of two units with a total size of 10,000 sq ft, the facility has been extended twice to meet rapidly growing demand for corrosion testing services, primarily from the oil and gas industry. Now covering 27,000 sq ft, it is one of the world’s largest independent laboratories dedicated to corrosion testing.

Getting the Best from Bunkers: WSS Advise

Wilhelmsen Ships Service (WSS) apprises that it has responded to changes in the marine bunker market with a campaign that aims to help shipowners get the best from their residual and distillate fuels. A consistent reduction in the quality of fuels available to shipowners, the need to comply with IMO and EU regulations on sulfur content and the adoption of slow steaming have created a ‘perfect storm’ of operational and compliance requirements, according to Jonas Östlund, Product Marketing Manager, Marine Chemicals, WSS. Taken together, he says these changes will have a profound impact over the next 10 to 15 years as refinery output shifts towards new fuels and the next wave of pollution regulations begins to bite.

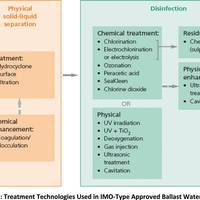

New BWM Regs Cometh - Are you ready?

The global market for BWT systems is predicted to grow to over $34 billion through 2020 in response to IMO and USCG-based ballast water discharge regulations (Frost and Sullivan, 2012). BWT systems are now manufactured by dozens of companies around the world, including traditional suppliers of marine equipment, suppliers of municipal water and wastewater treatment equipment, and shipbuilders. As of November 2013, 35 BWT systems have received IMO-type approval from foreign administrations, and 28 of these have been accepted into the AMS program by the USCG.

Drew Marine Gets Navy Worldwide MSC Supply Contract

In the latest listing of US Department of Defense, Navy, contracts Drew Marine USA has been awarded a one-year option for the worldwide supply, delivery and services for shipboard chemical treatment; foam testing, supply and disposal; industrial gases; and refrigerants for all U.S. naval ships of Military Sealift Command (MSC) and any other vessel specifically identified by MSC. Department of Defense state that Drew Marine USA, Inc., Whippany, N.J., is being awarded a $9,202,490 modification under a previously awarded indefinite-delivery/indefinite-quantity contract with firm-fixed-price delivery orders as above. The contract specifies that work will be performed worldwide and is expected to be completed November 2014.

Polytunnel Helps Museum Salvage WWll Airplane

A team of restoration experts is currently hard at work salvaging a unique World War II aircraft from the bottom of the English Channel. Using cutting edge restoration techniques within a purpose-built polytunnel from First Tunnels, the team hopes to have the rare Dornier 17 ready for exhibition within two years at the RAF Museum which is behind the ambitious project to raise the aircraft and end its watery exile. The Dornier 17 was central to the German war effort in its role as a Luftwaffe bomber used against the allies in the Battle of Britain.

Alfa Laval's PureBallast Receives Type Approval

PureBallast, Alfa Laval’s chemical-free system for ballast water treatment, has now received full Ballast Water Type Approval from DNV on behalf of Norwegian authorities. The certification, which was issued on June 27th, confirms that PureBallast complies in full with pending ballast water treatment legislation from the International Maritime Organization (IMO). Alfa Laval’s PureBallast system, which has been purchased for installation aboard more then 25 vessels since its launch in 2006, has rapidly established itself as the commercial leader in ballast water treatment. Now, having received full Ballast Water Type Approval on June 27th, it is also the only solution without chemical treatment processes to be certified IMO-compliant.

Marine Oil Spills and Response Options

Marine oil spills are subject to natural processes, which alter oil's physical and chemical properties. These factors ? as well as the type of oil spilled, the magnitude of the spill, and the physical conditions of the spill site ? determine the appropriate response for spill cleanup. Response options include mechanical recovery, chemical treatment and in-situ burning. Every spill scenario is unique and constantly changing. Careful assessment by experienced personnel is required for effective response performance. Natural spreading of the oil spill is a major factor in determining the response option most likely to succeed. The number and availability of personnel and equipment is also a major consideration.

Report on Ballast Water Management

The Congressional Research Service (CRS) issued a report summarizing ballast water management issues. It pointed out that high seas ballast water exchange is the most commonly used technique. Modification of a large ship so as to utilize onshore ballast water treatment facilities may cost an estimated $400,000. Retrofitting a vessel to treat ballast water may cost between $200,000 and $310,000 per vessel for mechanical treatment and around $300,000 for chemical treatment. (HK Law)