Houlder, Blue Sea Power Developing Floating LNG-to-power Barges for Greek Islands

Houlder, the design and engineering consultancy, is collaborating with Blue Sea Power, an integrated energy solution provider as a gas-to-power company based in Athens, to develop three innovative floating LNG-to-power barges (FSRPs).According to the partners, the FSRP barges, which are set to be operational by 2025, will efficiently provide greener, lower emission baseload and peak power to the non-interconnected islands of Kos, Chios, and Lesvos. This power will be used when existing renewable solar and wind energy utilization reaches its technical limits.

Singapore LNG Wants to Extract Chemicals from LNG

Singapore LNG Corp, operator of the city-state's liquefied natural gas (LNG) terminal, is designing a new facility to extract chemicals from the super-chilled fuel, in a project that could help boost the island's energy security.The company said on Wednesday it is working with Keppel Infrastructure through its wholly-owned subsidiary Keppel Energy and another industry partner on front-end engineering and design (FEED) for a natural gas liquids extraction facility at the terminal in Jurong Island…

Selvåg Senior: New LNG-Powered Purse Seiner/Trawler cuts GHG 42%

As nations commit to reducing greenhouse gases, a fishing vessel is designed to do its share. Designed by Norway’s Skipsteknisk and Selvåg AS, it is in build at Cemre Shipyard for Sorheim Holding, the Selvåg Senior is a remarkable concept. Capable of both trawling and purse seining, the 79.5- x16.2-m vessel will have a molded depth of 6.9 m. The RSW holds, in the DNV-GL classed vessel, will have a total volume of just under 2550 cu. m.. The main propulsion engine will be a medium-speed Wärtsilä 8V31DF, producing 4,800 kW at 750 RPM.

Sleipnir Completes Largest Ever LNG Bunkering

The world's most powerful semi-submersible crane vessel received the largest liquefied natural gas (LNG) bunkering ever completed.On Thursday, Titan LNG performed the bunkering of Heerema's Sleipnir, using the Coral Fraseri, Anthony Veder's LNG carrier in the Port of Rotterdam. The total quantity of LNG delivered was almost 3,300 metric tons, making this the largest LNG bunkering to have ever taken place. Sleipnir arrived at the Port of Rotterdam on Sunday, March 22, following a global campaign, and the LNG bunkering delivery took less then 24 hours to complete.

BV Appoves Cryo-Powered Regas System Design

Bureau Veritas Marine & Offshore (BV) has issued the first approval in principle for a new cold energy ‘Cryo-Powered’ regas system for use in FSRU applications.The approval has been issued to both Mitsui O.S.K. Lines, Ltd. (MOL) and Daewoo Shipbuilding & Marine Engineering Co., Ltd (DSME). The ‘Cryo-Powered Regas’ system is a cold power generation technology based on the Organic Rankine Cycle - a proven technology used in multiple onshore LNG terminals for decades.This will be the first time the system has been developed for use in a floating terminal.

MOL, DSME Collaborate on New FSRU Tech

Japanese shipping major Mitsui O.S.K. Lines (MOL) has entered into an agreement with Korean shipbuilder Daewoo Shipbuilding & Marine Engineering (DSME) to jointly develop a new technology to reduce environmental impact for Floating Storage and Regasification Units (FSRU).The new technology named ‘Cryo-Powered Regas’ will enable to utilize the LNG cold energy, which used to be disposed of, as power generation energy by adopting the Organic Rankine Cycle in the regasification process of the FSRU.Cryo-Powered Regas technology is expected to reduce fuel consumption and CO2 emission of FSRUs significantly.MOL and DSME plan to test the technology…

Singapore: LNG Terminal to Develop Data Center

The National University of Singapore's Faculty of Engineering (NUS), Singapore LNG Corporation (SLNG) and Keppel Data Centers Holdings join forces to develop new energy-efficient cooling technology for data centers.This innovation could further pave the way for more sustainable and compact data centers, said Singaporean conglomerate Keppel Corporation.With the rapid expansion of cloud-based services, AI, the Internet of Things and big data analytics, there has been an exponential demand across the globe for data centers in recent years. As the leading data center hub of Southeast Asia, Singapore accounted for around 50 per cent of the region's data center capacity in 2015.Due to the high internal load and the need for consistent cooling and operation in a tightly-controlled environment…

VeChain Inks Blockchain Deal for Chinese LNG Solution

Chinese enterprise blockchain company VeChain announced a deal for a liquified natural gas (LNG) management solution that will leverage the VeChainThor Blockchain.The partners are two of the leading Chinese energy and gas companies, ENN Energy Holdings and state-owned Shanghai Gas.In the introduced solution, ENN Energy Holdings Limited is responsible for the design and system construction of LNG-related business scenarios and is providing the necessary vehicles/equipment.In the pilot rollout of this solution, ENN Energy Holdings Limited will provide the onsite technical team and testing locations working within their existing businesses.

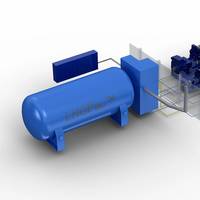

Wärtsilä Upgrades Fuel Gas Handling Solution

With LNG becoming increasingly viable and popular as a marine fuel, Wärtsilä continues to develop technical solutions that facilitate this trend. The latest Wärtsilä developments in this field involve an upgraded version of the Wärtsilä LNGPac, a fully integrated fuel gas handling system, and improvements to the coveted Wärtsilä Gas Valve Unit (GVU). Wärtsilä introduced the LNGPac in 2010. It comprises a complete system for LNG fuel handling, which when introduced included the bunkering station…