NYK to Stay Ahead 2022 with Digitalization and Green

Nippon Yusen Kabushiki Kaisha (NYK) announced that NYK formulates the new medium-term management plan “Staying Ahead 2022 with Digitalization and Green”. The new mediumterm management plan states NYK’s corporate vision and management approach over the next five years from April 2018, which are designed to achieve sustainable growth by expeditiously adapting to the altering business environment. The business environment surrounding NYK group is increasing its uncertainty as a consequence of today’s volatile shipping market condition, rising geopolitical risk and rapid technological evolution. To survive in such uncertain times, NYK group…

NYK: Staying Ahead with Digitalization, Green

Nippon Yusen Kabushiki Kaisha ( NYK ) announced that NYK has formulated the new medium-term management plan “Staying Ahead 2022 with Digitalization and Green”. The new medium-term management plan states NYK’s corporate vision and management approach over the next five years from April 2018, which are designed to achieve sustainable growth by expeditiously adapting to thealtering business environment. The business environment surrounding NYK group is increasing its uncertainty as a consequence of today’s volatile shipping market condition, rising geopolitical risk and rapid technological evolution. To survive in such uncertain times,…

MHI Develop Double Column Machining Center

Mitsubishi Heavy Industries, Ltd. (MHI) has completed the development and begun full-scale marketing of a double column machining center - dubbed the "LH250" - capable of high-precision machining of workpieces up to 2 meters in length. The new unit not only offers significantly enhanced vibration absorption capability in the machine structure and greater rigidity in the high-speed main spindle, it also incorporates MHI's unique main spindle lubrication cooling technology and suppresses self-heating of the machine normally caused by long hours of continuous operation, which take a toll on machining precision. Through these innovations, the LH250 has achieved machining with 5 micrometer (µm, 0.001 millimeter) level precision, the highest level in the same size machine category.

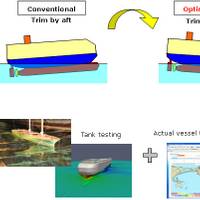

MOL-Developed Optimum Trim System

TOKYO—Mitsui O.S.K. Lines, Ltd. (MOL; President: Koichi Muto) today announced the joint development of an optimum trim system for vessels, along with Akishima Laboratories (Mitsui Zosen) Inc. A pilot test of the system, using a 6,400-unit car carrier, showed an increase of up to 4% in fuel efficiency compared to a conventionally equipped vessel, which in turn contributes to a significant reduction in CO2 emissions. The optimum trim system quantitatively assesses MOL captains’ extensive practical knowledge of vessel running attitudes through tank testing and actual ship test.