MOL's Propeller Boss Cap Fins earns Guinness World Record Title

Mitsui O.S.K. Lines, Ltd. announced that its Propeller Boss Cap Fins (PBCF), sold by its group company MOL Techno-Trade, Ltd. was certified as the “Best-selling Energy-Saving Ship Appendage Brand (Cumulative)”, by Guinness World Records, and received the official certificate on December 23, 2021.This award is based on the cumulative 3,748 PBCFs sold (the sales record with 3,516 vessels including twin-screw vessels equipped with PBCF) as of the end of December 2020.PBCF was co-developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd., and Nakashima Propeller Co., Ltd.

MOL Techno-Trade in Green Initiative

Japanese shipping giant Mitsui O.S.K. Lines (MOL) announced that its group company MOL Techno-Trade has joined a Green Award Program aimed at promoting high-quality shipping.The program is run by the nonprofit Green Award Foundation, which was established with the objectives of protecting the marine environment and enhancing safe operation.The program aims to improve the quality of vessels and mariners and protect the marine environment by certifying vessels for excellence in safety and low environmental impact. Companies that share the foundation's goals support them by providing incentives.Eleven MOL Group-operated vessels have earned certification from the Green Award Foundation.

MOL's PBCF Reduces 3-5% in Fuel Consumption

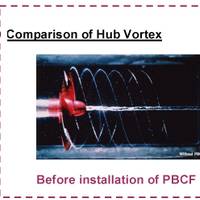

Mitsui O.S.K. Lines (MOL) announced that its jointly developed Propeller Boss Cap Fins (PBCF) received the 2017 Nikkei Global Environmental Technology Award, which is presented by Nikkei Inc. The PBCF, which is a device that improves propeller efficiency by breaking up the hub vortex generated behind the rotating propeller and offers an energy savings of around 3-5% compared to similar vessels not equipped with the PBCF, was co-developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd., and Nakashima Propeller Co., Ltd. (called Mikado Propeller Co., Ltd. at the time), and is being sold by MOL Techno-Trade, Ltd. The PBCF has been sold for more than 3,200 vessels all over the world since 1987, when it started sales of the conventional PBCF.

Vancouver Port Selects “PBCF” as Equipment Designated

Mitsui O.S.K. Lines, Ltd. today announced that Propeller Boss Cap Fins (PBCF) was selected as a vessel quieting technology by the EcoAction Program implemented by Port of Vancouver, Canada. PBCF was jointly developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd. and Nakashima Propeller Co., Ltd. (Note 1), and is being sold by MOL Techno-Trade, Ltd. The Vancouver Fraser Port Authority’s EcoAction Program offers discounted harbour due rate to vessels that have implemented voluntary emission reduction measures and other environmental practices. As of January 1, 2017, vessels equipped with PBCF and transiting to the Port of Vancouver will be eligible for bronze level recognition and a 23% discount in harbour dues.

Stevens Institute Dedicates ABS Engineering Center

ABS Chairman, President and CEO Christopher J. Wiernicki addressed attendees at the dedication ceremony for the new ABS Engineering Center at Stevens Institute of Technology on 17 November 2016, encouraging students to use these facilities to work toward solving industry challenges. “The ABS Engineering Center provides an environment both for learning the various engineering disciplines and for looking ahead toward new technologies that could transform the marine industry,” Wiernicki said. “Over the years, ABS and Stevens have been aligned with a mutual purpose of fostering learning and advancing innovation for the next generation of leaders. As a global technology leader, ABS is committed to supporting research that enhances safety in the marine and offshore environments.

Ohmsett: Advancing Spill Response Every Day

The National Oil Spill Response Research and Renewable Energy Test Facility has been an integral part of the spill response community for more than three and a half decades. Tucked away on the shores of the Sandy Hook Bay in central New Jersey resides Ohmsett – The National Oil Spill Response Research and Renewable Energy Test Facility. It has been an integral part of the spill response community for more than three and a half decades. Government agencies, private industry, and oil spill response organizations from around the world have visited the facility for testing, research and training.

Oil Under Ice

The U.S. How did an urgent requirement to build a road to Alaska end up helping to design submarines and to recover oil spills in the Arctic ice? The Army Corps of Engineers was faced with a monumental challenge of building a highway to connect the “lower 48” to Alaska during World War II to keep America’s northernmost territory secure from invasion. The road crossed hundreds of miles of wilderness, and much of the roadbed sat up permafrost, presenting challenges to America’s roadbuilders.

Cold and Calculating: Dealing with Ice in Domestic Waterways

Army research laboratory helps vessels deal with ice in domestic waterways. Ice, snow and extremely low temperatures can put a big chill on maritime operations in ports, lakes, rivers and waterways. Thanks to the U.S. Army’s Corps of Engineers Cold Regions Research and Engineering Laboratory (CRREL) in Hanover, New Hampshire, mariners have a better understanding regarding phenomena such as icing on superstructures, brash ice and propulsion systems and controlling ice dams. And…

Marine News January 2015 - Editor's Note

Our annual Ferry and Passenger Vessel edition kicks off the New Year in high gear, even if oil prices aren’t necessarily following suit. As vessel operators – our ferry drivers included – celebrate lower bunker prices, another maritime subset frets over what might happen to the offshore service market if the downturn in crude oil prices continues unabated for a significant length of time. That said; if your market focus is ferries and/or passenger vessels, then you won’t find another more comprehensive or diverse look at this sector than that which is depicted in the pages that follow. It turns out that the passenger vessel and ferry industry is a forward-thinking, innovative and problem solving group of businesses.

USCG R&D Team Up Agencies for Arctic Awareness

For a second year, members of the Coast Guard Research and Development Center, based in New London, Connecticut, make their way to the large ice floes of the Arctic Ocean to conduct research and test new equipment and technologies with the aim of expanding our knowledge and enhancing our ability to respond to potential hazards and emergencies brought on by increased vessel traffic through the region. It’s a mission as big and as important as the Arctic itself and one they couldn’t do alone. When RDC members depart for the Arctic, they do so aboard the Coast Guard Cutter Healy, a 420-foot icebreaker homeported in Seattle, Wash., that serves as a perfect platform for conducting Arctic research.

Coast Guard Preps for Arctic Research

A team of scientists from the U.S. Coast Guard (USCG) Research and Development Center (RDC) will depart from Seward, Alaska, for a technology evaluation in the Arctic aboard the Coast Guard Cutter Healy Aug. 8, the Coast Guard announced. According to the USCG, the RDC is leading a multiagency team to support Arctic Shield 2014, a 17th Coast Guard District initiative. The purpose of their month-long evaluation is to improve USCG capabilities in the Arctic region, specifically in the areas of boat operations, communications, navigational safety and oil spill response.

Scientific Team Arctic-bound Aboard Cutter 'Healy'

A team of scientists from the Coast Guard Research and Development Center (RDC) is to depart shortly from Seward, Alaska, for a technology evaluation in the Arctic aboard the Cutter 'Healy informs USCG. The RDC is leading a multi-agency team to support Arctic Shield 2014, a 17th Coast Guard District initiative. The purpose of their month-long evaluation is to improve Coast Guard capabilities in the Arctic region, specifically in the areas of boat operations, communications, navigational safety and oil spill response. “The RDC plays a key role in charting the service’s future efforts in the Arctic by evaluating new and emerging technologies for applicability to Coast Guard operations in a harsh and remote environment,” said Capt. Dennis Evans, commanding officer of the RDC.

ABS Funds New Maritime Engineering Laboratory

Class Society, ABS donates US$ 3-million to Stevens Institute of Technology to create a newlaboratory complex in the Davidson Laboratory. The donation will be used to create a new civil, mechanical and naval engineering laboratory complex in the Davidson Laboratory which will bear the Bureau's name. Stevens will construct a 25,000-square-foot facility above the historic Davidson Laboratory, including new laboratories critical to the Stevens strategic plan. The complex will meet the research and instructional needs of approximately 800 Stevens students annually working in such areas as robotics, underwater systems, land- and water-based vehicles and ocean and weather sensors.

Energy-Saving Propeller Boss Cap Fins System

Mitsui O.S.K. Lines, Ltd. (MOL; President: Koichi Muto) and MOL Techno-Trade, Ltd. (MOL Tech; President: Hidehiro Harada) today announced that the energy-saving Propeller Boss Cap Fins (PBCF), developed by MOL, West Japan Fluid Engineering Laboratory Co., Ltd., and Mikado Japan, Ltd., and sold by MOL Tech, has now been ordered for 2,000 vessels worldwide. The PBCF is an energy-saving device attached to the propellers of a vessel. It breaks up the hub vortex generated behind the rotating propeller…

Feature: Designing People

Few would argue with the notion that a healthy commercial marine industry needs new naval architects entering the business of designing and engineering ships and offshore structures. New naval architects bring new technology and a fresh way of looking at old problems. The University of New Orleans School of Naval Architecture and Marine Engineering (NAME) produces a dozen or so people per year who have mastered this very difficult subject. At any given time UNO has about 145 people enrolled in the NAME program leading to a Bachelor's degree, the most students in any program of its kind. The school also offers Master's and Doctorate degrees in the field. There are currently 18 students in the MS program and three in the aspiring Ph.D candidates. The first Ph.D was graduated in May 2003.

Propulsion News

Propeller Boss Cap Fins (PBCF) is a propeller enhancing device, which is designed to cut fuel consumption and exhaust gases by up to five percent while incurring no additional maintenance cost once installed. The unit, according to H. Yumoto Manager of PBCF Div. Mitsui O.S.K. Techno Trade, Ltd., is now operational on 720 ship worldwide. The PBCF rectifies the propeller hub vortex and recovers rotational energy otherwise lost in the propeller slip stream. Increasing propeller thrust by over one percent and reducing propeller torque by over three percent, the PBCF reportedly results in fuel savings of up to five percent or compared to vessels operating at equivalent speeds but without the PBCF, alternatively, a 1.5 percent increase in speed at the same engine output.