Keel Laid for Seaway 7's Offshore Wind Installation Vessel 'Seaway Ventus'

A keel-laying ceremony was held earlier this week for Seaway 7’s new offshore wind turbine installation vessel Seaway Ventus.The ceremony was held on Monday, June 6, at the China Merchants Heavy Industry (CMHI) Haimen facility, Nantong.The GustoMSC NG-14000XL-G jack-up vessel was originally ordered by OHT, with which Seaway 7 merged in 2021."This is a very important and satisfying milestone for the Seaway Ventus construction project, marking the period where all the fabricated…

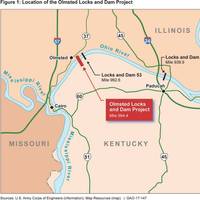

Olmsted: Online & Open

After more than 30 years of frustratingly slow progress, cost overruns and more than a few mistakes, Olmsted is finally poised for success. That’s something to celebrate.It is official: The U.S. Army Corp of Engineers (USACE) wants Olmsted operational by October. After more than 30 years, the ribbon cutting to officially open the Olmsted Locks and Dam took place on August 30. The very old (1929) upstream locks and dams – Nos. 52 and 53, which Olmsted is replacing – will be dismantled by December 2020. Before that happens, Olmsted’s performance will be tested and confirmed.

Marine Fabrication Returns to Southampton

Marine engineering services firm SMS is midway through a contract for Woods’ Silver Fleet to build three huge pontoons for the Thames. The works amount to circa 750 metric tons of fully fabricated steel pontoons and over 5,000 man hours of specialized, local, labor in Southampton, Hampshire, U.K.Chris Norman, the managing director of Southampton Marine Services (SMS), said, “This project is of significance not only to SMS but also the local shipbuilding community. “It’s the first time in 13 years…

Gibdock Wins Exhaust Scrubber Project

Gibdock has secured an exhaust gas scrubber retrofit project covering five vessels operated by ship management major Norbulk Shipping and owned by global shipping group Vroon. The contract represents a sizeable debut in specialized EGS work. With all five ships also undergoing special survey drydocking, the job is the Gibraltar yard’s largest single assignment in 2015. The landmark project is also the first ship-series SOx abatement technology retrofit win for any Southern European yard.

MacGregor to Provide Seven Stockholm RoRo Linkspans

UK's MacGregor, part of Cargotec, says it has secured a contract to supply 7 hydraulically-operated linkspans to the Port of Stockholm in Sweden. The linkspans have been ordered as part of a port development project to extend the capabilities of Stockholm's largest harbour, Värtahamnen and Kapellskär harbour. Five linkspan units will be installed in Värtahamen and two in Kapellskär. The contract contains a number of options for further units intended for other sites within the port. "The design of the linkspans is based on, and developed from, the best characteristics of a series of successful deliveries," says Clas Hedelin, Sales Manager, Port Solutions, RoRo Systems.

GAC Overcomes Challlenges, Delivers to Central Africa

GAC UK & GAC Seaforth overcome challenges to deliver cargo to LakeTanganyika, Burundi, for Surestream Petroleum oil exploration. Independent oil exploration company Surestream Petroleum Ltd, headquartered in Reading, UK, contacted energy sector specialists GAC UK for help with shipping 60 tons of cargo to their seismic operations base on Lake Tanganyika, located to the west of Tanzania and also bordered by Burundi, the Democratic Republic of Congo and Zambia. The shipment comprised fabricated steel sections, stores, tools, chemicals, high value seismic equipment and a 10m chase boat. GAC was also appointed as the main agent to air-freight stores to Burundi and for a high-priority task to andfrom Malawi.

News: Nichols Brothers Launch Sternwheeler

Nichols Brothers Boat Builders of Whidbey Island and Seattle-based American West Steamboat Company, owned by Henry Hillman, Jr., CEO of Oregon Rail Corp., launched the newly constructed overnight sternwheeler cruise ship Empress of the North. The 360-ft. sternwheeler was transferred on a specially designed rail system into Holmes Harbor, where it launched. Designed by Seattle naval architects, Guido Perla & Associates, construction of the Empress of the North began at Nichols Brothers' shipyard in April, 2002. She is the largest ship built by Nichols Brothers, with over 350 employees on the job and approximately 300,000 man-hours involved in the project.

Nichols Brothers Launch Sternwheeler Cruise Ship

Nichols Brothers Boat Builders of Whidbey Island and Seattle-based American West Steamboat Company, owned by Henry Hillman, Jr., CEO of Oregon Rail Corp., have launched the newly constructed overnight sternwheeler cruise ship Empress of the North. Beginning at 5:00am on Monday, June 16, 2003, the 360-foot sternwheeler was transferred on a specially designed rail system into Holmes Harbor, where it launched at high tide at approximately 8:45pm. With the launch open to the public, an estimated 5,000 people showed up for the event. Designed by Seattle naval architects, Guido Perla & Associates, construction of the Empress of the North began at Nichols Brothers’ shipyard in April, 2002.

Cargo Handling: Molten Sulphur Tanker Sails Four Years Sans Freeze-Ups

The operator of the world’s largest and most modern molten sulphur tanker has enjoyed four years of near-continuous service, thanks in part to the ship’s innovative thermal maintenance system. Sulphur Carriers, Inc., a subsidiary of International Shipholding Corporation, keeps M/V Sulphur Enterprise at sea hauling around 24,000 long tons of molten sulphur per trip. “We’ve had zero freeze-ups and zero maintenance associated with the bolt-on piping and valve heating system,” says Peter Johnston, Sulphur Carriers’ VP of operations. For reportedly the first time on any sulphur transport ship, a bolt-on heating system keeps the molten cargo flowing and the ship on schedule by preventing costly delays due to frozen pipes and valves.