Amogy Brings Ammonia Into the Mix

Ammonia is one of several renewable fuels seen as an option to help the maritime industry decarbonize.One of the companies working to unlock the fuel’s potential is Brooklyn, N.Y. based Amogy, developer of an onboard system that feeds liquid ammonia through a cracking process to create hydrogen on demand for power generation via fuel cell—without carbon emissions.Having already demonstrated its technology on an aerial drone, tractor and semi-truck, Amogy is currently working to…

Progress Reported in Ammonia Tugboat Retrofit Project

A first-of-its-kind project to convert a 1950s tugboat to run on ammonia-to-power technology is moving forward, with several key milestones recently achieved, involved technology partners report.The Amogy-led retrofit project involves a comprehensive overhaul of the tugboat's original diesel generators and electric motors, integrating the Brooklyn startup's 1-megawatt ammonia-to-power system.Once installed, Amogy’s onboard solution will feed liquid ammonia through its cracking modules integrated into a hybrid fuel cell system that will provide zero-carbon power to the vessel’s electric motors.

Berg Propulsion to Provide Systems Integration for Hybrid Tug

Berg Propulsion has been selected to provide control and propulsion technology for what will be one of the largest hybrid tugs ever delivered, after owner Buksér og Berging AS (BuBe) agreed specifications with Turkey’s Uzmar Shipyard for its latest newbuild.Berg has been contracted to provide the full electrical power and control package for the Robert Allan-designed Rampage 4100BB-H tug, which will join BuBe’s North Sea operations in December 2024. Supply will include the electric motors…

BIO-SEA BWTS Developed for U.S. Navy

BIO-UV Group said that a BIO-SEA Ballast Water Treatment System (BWTS) designed for the Unites States Navy (USN) completed Factory Acceptance Tests (FAT) at the production facility in France. BIO-UV Group now has approval to ship the system to a USN facility for operational testing.BIO-UV Group is working with The Columbia Group, Inc. (TCG), a U.S.-based engineering partner, and prime contractor in the development project. Teaming up with BIO-UV Group design engineers, TCG was…

World’s Largest Methanol Engine Passes Factory Acceptance Tests

The world’s largest methanol-powered two-stroke engine—an MAN B&W G95ME-LGIM type built by Hyundai Heavy Industries' Egine & Machinery Division (HHI-EMD)—has successfully passed factory acceptance tests (FAT) in South Korea.MAN Energy Solutions developed the ME-LGIM dual-fuel engine for operation on methanol, as well as conventional fuel. The engine is based on the company’s proven ME-series, with its approximately 8,500 engines in service, and works according to the Diesel principle.

Hydrotug: World's First Hydrogen-powered Tug Launched

Hydrotug, the world's first hydrogen-powered tugboat, has been launched at Armón Shipyards in Navia, Spain, marking a key milestone on the path toward wider adoption of the sustainable, climate neutral fuel in workboat applications.Remaining outfitting work will be completed over the next few months ahead of sea trials later this year. The groundbreaking vessel is scheduled to be delivered by the end of this year and enter full operations in the first quarter of 2023 for shipping…

GE to Provide Propulsion Systems for the new French Navy Logistic Support Ships

The first MV7000 drives for the LSS FLOTLOG program has successfully passed their Factory Acceptance Tests at GE Power Conversion Nancy Factory, reaching a first milestone for the new fleet of logistic support ships (LSS) of the French Navy.It follows the contract signed in 2020 between GE Power Conversion and Chantiers de l’Atlantique to provide systems for the four LSS to be built by the Shipyard for the French Navy, under the contract management of the Organisation for Joint Armament Co-operation (OCCAR)…

Remote FATs Fill COVID-19 Service Gaps

With the coronavirus crisis continuing with no end in sight, Techcross says it is using various solutions to solve customer service issues. Videoconferencing has already become the most basic contactless activities, and the engineering team is filling on-site service gaps through new methods such as training local engineers or providing remote commissioning service.The pandemic has made it difficult for Techcross staff to visit clients and conduct factory acceptance tests (FATs)…

The Advantages of Variable Speed Gensets

Due to economic necessity, commercial ship operators have become increasingly focused on finding cost-optimized solutions to operate their vessels. In turn, power solutions providers like Rolls-Royce have been dedicated to finding ways to deliver the right technologies that will meet an operator’s specific requirements.In recent years, interest in variable speed units as a driver of certain commercial vessels has gained interest. Variable speed technology allows the speed of an engine to be regulated and adjusted according to the electrical load that is connected…

MAN Gensets Delivered for Italian Patrol Vessel

Following an order won in October 2016, MAN Diesel & Turbo SE has delivered gensets for the first of new series of Italian Navy offshore patrol vessels (OPV) and has secured an order for second shipset. After the successful factory acceptance tests (FAT) in July 2017 witnessed by a delegation from the Italian Navy, MAN Diesel & Turbo SE has delivered four MAN 12V175D generating sets to Fincantieri Muggiano Shipyard, where the first of a class of seven Multipurpose Offshore Patrol Vessels (Pattugliatore Polivalente d'Altura - PPA) is currently under construction.

Elcome Supplies Electronics for Abu Dhabi New Builds

Elcome International is supplying electrical switchboards, safety, monitoring and control systems for three vessels under construction at Abu Dhabi Ship Building (ADSB). Elcome’s scope of work included supply, installation and commissioning of main switchboards and electrical systems, bridge and engine room consoles, tank gauging and fire detection systems. The three vessels are being built for a customer in the Middle East for delivery in 2017. “These orders from ADSB represent a significant achievement in our growth as a major supplier for newbuilds as well as retrofits…

Bridges Refit on Two Holland America Line Ships

Two major bridge refit contracts have been completed by Radio Holland USA on Holland America Line’s cruise ships Oosterdam and Prinsendam. The bridge refit on board the M/S Oosterdam was concluded in Palermo, Sicily in early May. Then just days later Radio Holland continued with a bridge upgrade project for the M/S Prinsendam, which took place in Freeport, Grand Bahama. The latest refits follow refit work on M/S Noordam and Westerdam in 2014 and 2015. Rob van den Hof, Nautical Superintendent of Technical Operations from Holland America Line…

Servowatch IPMS Completes FATs for UK Navy

The fully integrated platform management system Servowatch designed and built for three new offshore patrol vessels for the U.K. Royal Navy has completed BAE Systems’ Factory Acceptance Tests (FAT). Servowatch, the supplier of advanced integrated ship control systems, will now integrate the IPMS package at BAE Systems’ shipyard on the River Clyde, Glasgow, Scotland, where the next-generation OPVs are currently under construction. The Servowatch scope of supply includes a fully integrated control and management system for the vessels’ propulsion…

Canadian Frigates Get a Radar Upgrade

German navigation system manufacturer Raytheon Anschütz has completed factory acceptance tests and delivery of 12 sets of navigation radars for the Canadian Navy’s Halifax-class frigates. The scope of onboard systems covers X-/ and S-Band radars with high-performance detection capabilities. Raytheon Anschütz said the radars have been enhanced with advanced features in accordance with the Canadian customer requirements, including new radiation control and pulse blanker interfaces…

MAN Diesel & Turbo Reports ME-GI Milestones

MAN Diesel & Turbo reports that its ME-GI engine has now received more than 100 orders. FLEX LNG announced on February 2 that two-stroke slow-speed ME-GI main engines will be used as the propulsion system for two LNG carriers to be built at Samsung Heavy Industries. The expected delivery dates of the vessels have been postponed from Q1 2017 to Q1 and Q2 2018. Ole Grøne, Senior Vice President Low-Speed Sales and Promotions, MAN Diesel & Turbo, said, “With our ME-GI order book now having passed the 100-unit milestone…

SOSI Delivers Mooring Winches; Completes Test Pad

Sound Ocean Systems, Inc. (SOSI) announced the delivery of two unique mooring winches, both tested on its newly constructed test pad at its primary manufacturing facility in Sultan, Wash. SOSI recently delivered two all-electric, custom designed, VFD controlled large mooring winches developed for Oregon State University and the University of Washington. Although configured differently, both the 175 HP OSU Heavy Lift winch and the 75 HP UW Medium Lift winch contained SOSI’s continuous position sensing level wind system. The Heavy Lift Winch is capable of deploying or recovering 25,000 lbs.

Savvy Fuel Management Fuels TOTE’s Growth

As Tote pioneers the use of natural gas as a marine fuel with two groundbreaking projects, Anthony Chiarello combines the strength and diversity of the Saltchuk group of companies with a forward-thinking, environmentally correct Tote business plan. As TOTE prepares to bring the world’s first natural gas-powered containerships to the maritime industry, the firm will also be the first to convert its existing fleet to run on natural gas. Two Orca Class vessels, operated by Totem Ocean Trailer Express (Totem Ocean) in the Alaska trade, will be converted with minimal time out of service and return as the most environmentally advanced ships in the nation.

TOTE’s Marlin Class Ships Enter Next Build Phase

The arrival of the world’s first dual-fuel slow-speed engine to General Dynamics’ NASSCO Shipyard marks the next phase of construction for TOTE’s Marlin Class vessels, projected by TOTE to be the world’s safest and cleanest containerships. Doosan Engine, under license from MAN Diesel and Turbo, delivered the first 8L70ME-GI engine. Earlier this year, Doosan completed the engine’s Factory Acceptance Tests, a culmination of months of testing to ensure compliance with U.S. regulations and restrictions.

New Wärtsilä X72 Powerplant Passes Crucial Test

Wärtsilä said that the first ever Wärtsilä X72 mid-bore, low-speed engine has successfully passed the factory acceptance test. This milestone verifies that the engine fulfils the design criteria for performance and functioning, and that it has been accepted by the customer and the Lloyd's Register of Shipping classification society. The tests were carried out at the Doosan Engine Co. Ltd factory in South Korea, where the engines are being produced under license from Wärtsilä. Wärtsilä launched its low-speed Generation X engine series in May 2011. The Wärtsilä X72 engine offers exceptional efficiency and fuel consumption performance to provide a favourable Energy Efficiency Design Index (EEDI).

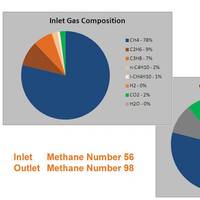

Making Flare Gas Useful

Wärtsilä has developed the GasReformer, a product which converts associated gas, which is often flared, into usable fuel for its dual-fuel engines. When producing oil, associated gas is also released from the deposits. In many places this gas is commonly burnt off in gas flares, a waste of energy and a pollutant of the atmosphere. In addition to useful methane, this gas consists of heavier hydrocarbons including ethane, propane and butane. The composition of the gas typically also vary during the production phase of the oil field.

Kongsberg Completes K-Master FAT & Sea Trials for New PSV's

New aft-bridge operator station integrated with DP and thruster control. Kongsberg Maritime has successfully completed Factory Acceptance Tests for the K-Master aft bridge systems being delivered to two Platform Supply Vessels (PSV) built at Havyard in Leirvik for owner Sartor Offshore and Supply Service. The vessels are part of a four newbuild series, all featuring KONGSBERG K-Master, K-Pos Dynamic Positioning, C-Joy joystick control and K-Thrust thruster control. The FATs were for Havyard 103 and 106, vessels number 2 and 3 in the series and are due for delivery to the owner in Q1 2012.

Marine Diesel Engine Passes Acceptance Test

The Wärtsilä X35 is a completely new Wärtsilä engine that, together with the Wärtsilä X40, will cover the small-bore end of the market. The engines will be used for smaller bulk carriers, product tankers and container feeder vessels. It is a segment where Wärtsilä has not been present for a number of years. This new electronically controlled low speed engine, the Wärtsilä X35, has successfully passed its Factory Acceptance Tests (FAT). The tests of the two engines took place at both the 3.MAJ Engines & Cranes company facilities in Croatia, and the Yuchai Marine Power Co., Ltd.

Rapp Hydema Completes FAT for ARRV Deck Machinery

Factory Acceptance Tests (FAT) of Rapp deck machinery for the Alaskan Regional Research Vessel (ARRV) were recently undertaken successfully in Seattle. Other than winches, the tests included the Load-Handing System (LHS), which was tested in a unique upside-down configuration. A UNOLS delegation, along with representatives of Marinette Marine Shipyard and the U.S. Navy’s OpNav office, witnessed the tests. The diverse machinery package was manufactured locally in compliance with the American Reinvestment and Recovery Act (ARRA), the source of original financing for the project. Dan Markovic, Rapp Seattle’s Engineering and Program Manager for the ARRV project, said that “the results of the FAT met and, at times, exceeded our expectations.