Optimizing Blast and Paint Processes in New Construction Shipbuilding

The efficacy of surface preparation and coating application in the new construction shipbuilding industry is fundamentally anchored in a well-coordinated, integrated approach. This intricate process, essential for achieving top-tier corrosion control, is methodically segmented into five crucial stages:Raw material entryPainting the modulesSmall partsPainting of erection joints at the module levelFinal paint and ship's completion. Each stage is crucial in its own right but achieves…

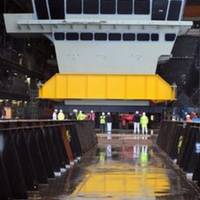

UK Aircraft Carrier Forward Island Module to be Shipped

The BAE Systems built Forward Island for 'HMS Queen Elizabeth' to transit by barge for mounting in Rosyth shipyard. The iconic Forward Island, known as Upper Block 07, is the hub of the ship as it contains the main bridge and approximately 100 vital mission systems compartments. Weighing 680 tonnes, this is the first block to depart with her final paint colours applied, all windows fitted and consoles installed, along with 43km of cables and 3,101 pipes. It also proudly displays the HMS Queen Elizabeth crest.

Hyundai Starts Export of LNG Fueled Engines

The new gas engine runs on liquefied natural gas rather than heavy crude oil and has a maximum power output of 13,000 bhp. The HiMSEN H35/40GV can be used to generate power for onshore power plants, commercial ships, and offshore facilities including drillships. The new engine emits 20% less carbon dioxide than diesel engines, reduces NOx emissions by 97% to reach world’s lowest level of 50 ppm, and improves engine performance by 47%. The Ulsan, South Korea-based company will export the engine to an onshore gas-powered power plant in the Middle East after final paint and packing work. Mr.