Turkish Shipyard Cuts First Steel for Offshore Wind Farm Support Vessel for Dutch Owner

Turkey's Tersan Shipyard last week celebrated the steel cutting of NB1121, the second offshore wind farm support vessel being built for Acta Marine projects.The shipyard is building two DP2 construction service operation vessels (CSOV) powered with Methanol and MDO/HVO for the Dutch vessel owner. The construction of the first vessel kicked off in January.Designed by Ulstein Design & Solutions AS with the cooperation of Acta Marine, the two vessels are planned to serve in the offshore wind market.

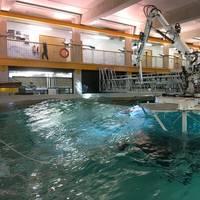

Tech File: A Robotic Reach in Offshore Wind

With a background in subsea and offshore, coming up with new ideas is the norm’ for UK-based engineering consultancy STL (Submarine Technology Limited), writes Elaine Maslin.The last few years have been no different. The company has been focusing on ship-based robotics, including robotic arms. These aren’t just any robotic arms – they’re motion compensated systems for deploying/recovering people and robots to and from fixed or moving objects. That could be wind technicians to…

A Robotic Reach in Offshore Wind

With a background in subsea and offshore, coming up with new ideas is the norm for UK-based engineering consultancy STL (Submarine Technology Limited), writes Elaine Maslin.The last few years have been no different. The company has been focusing on ship-based robotics, including robotic arms. These aren’t just any robotic arms – they’re motion-compensated systems for deploying/recovering people and robots to and from fixed or moving objects.That could be wind technicians to an…

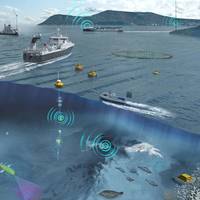

Region in Focus: Norway’s West Coast Shipping Tech Hub

Two load-bearing pillars of Norway’s leading maritime industry cluster in Sunmøre on the country’s west coast – offshore energy and the expedition cruise sector – took severe knocks from plunging energy prices in the 2010s followed by COVID-19. However, a recent tour of the region found the cluster in recovery mode.At the time, the cluster’s diversification strategy was to dive into the emerging expedition cruise sector: small, highly sophisticated ships designed to operate in some of the world’s most sensitive environments incorporated features including the highest ice-class…

Ampelmann Wins North Sea Contracts

Ampelmann has strengthened its position in the North Sea this year after being awarded four new contracts and two extended scopes of work in the basin.The projects will see six E-type gangway systems deployed for planned shutdown campaigns and ongoing fabric maintenance support by different major operators across the UKCS.Utilising motion compensation technology, Ampelmann’s E-type is the largest system in the company’s portfolio and is ideally suited for the harsh environment of the North Sea, able to compensate high sea states up to 4.5m Hs.The gangway, which can transfer a full shift of up to 40 people in 15-20 minutes, enables offshore workers safe and easy access to a variety of assets…

First Damen Fast Crew Supplier with Ampelmann Gangway

The partnership between Damen Shipyards Group and Ampelmann to extend the benefits of motion-compensated gangway systems to fast crew supply vessels has reached a major landmark. At the end of March, the first Damen fast crew supply (FCS) vessel to be fitted with an Ampelmann L-type system began operations in the Gulf of Guinea. This marks a significant step forward in the move towards bringing the latest advances in safe and flexible marine access to a wider array of oil and gas operations. Damen and Ampelmann have together been promoting their integrated solutions combining Damen’s FCS range and Ampelmann’s systems and now, thanks to the vision of Nigerian offshore services company LATC Marine and its client ExxonMobil Nigeria, the first has entered service.

L.A.T.C Marine to Install Two Ampelmann Systems

Ampelmann has secured two contracts with vessel owner L.A.T.C Marine Limited, on behalf of ExxonMobil, for the supply of two L-type gangway systems, offshore Nigeria. Following successful sea trials of the L-type gangway system, the integrated solution was approved for operations. Vessel owner L.A.T.C Marine has installed the personnel transfer system on its Damen FCS-5009 Fast Crew Supplier vessel Dijama for in field operations with ExxonMobil. The L-type is particularly suited to small, crew change vessels and allows a continuous flow of up to 50 personnel every five minutes. Gbolahan Shaba, CEO, L.A.T.C. Marine, said: “We are proud to have partnered with Damen and Ampelmann in delivering one of the most innovative solutions for the Nigerian upstream industry in recent years.

Crewboat Delivered to Caspian Marine

Built Built by Austal Ships, Rashid Behbudov, sistership to the Muslim Magomeyev and the second Incat Crowther 70m Catamaran Fast Crew Boat, has been delivered for Caspian Marine Services. Muslim Magomayev, the first of this design developed by Incat Crowther, was built by Incat Tasmania and delivered to CMS in 2014. Both Muslim Magomayev and Rashid Behbedov are engineered for the Ampelmann walk-to-work system, which transfers crew to offshore platforms in day-to-day operation as well as in emergency situations.

ABS Makes it Safer to ‘Walk to Work’

ABS announced the publication of The ABS Guide for Certification of Offshore Access Gangways. The new Guide addresses certification for safety systems used for “walk to work” (W2W) crew transfers. “As advanced crew transfer options become the norm in the offshore oil and gas industry, more and more companies want to benefit from W2W vessels and are looking to ABS for safety guidance,” says ABS Chief Technology Officer, Howard Fireman. Offshore access gangways with motion compensation systems are deployed and connected to the fixed or floating platform, maintaining the connection via telescoping features that provide a flat, inclined walking surface between the offshore support vessel and the delivery point.

Motion Compensation Aids Offshore Lifeboat Lift

In a refurbishment program to upgrade lifeboats on offshore platforms, Ampelmann completed a second successful reinstallation using its full motion compensation technology. The eight-metric-ton lifeboat was kept completely stationary above the vessel deck, to allow lifting by the platform’s davit cranes. Traditionally, refurbished lifeboats are reinstalled on the offshore structure in the following manner: a platform supply vessel takes the lifeboat offshore, where it is lifted from the deck to the sea.