VIDEO: Basjan Faber Discusses the Creation of C-Job’s Customizable TSHD Series

With an eye on an aging trailing suction hopper dredge fleet, C-Job is set to debut an innovative new THSD design series with a focus on modularity and sustainability. Basjan Faber, CEO, C-Job Naval Architects, discusses the dredging market and the new design with Maritime Reporter & Engineering News.Without equivocation, the Dutch know dredging. The country name itself—“the Netherlands”—literally means "the lowlands" and refers to the geographic features of the land being both flat and down river from higher areas…

New Software Aims to Transform Ship Maintenance

A consortium of technology suppliers led by BAE Systems is developing software that monitors the equipment, fuel and energy performance of a ship to provide real time information that will help the U.K. Royal Navy and commercial organizations better manage their fleets. The technology known as Ship Energy Assessment – Condition Optimization & Routing Enhancement System (SEA-CORES) analyzes big data from the complex systems on board a ship to provide a live model of its performance wherever it is in the world.

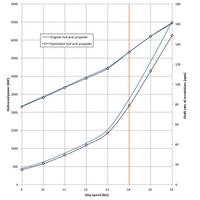

New Propeller Optimization Process Can Analyze 10,000 Designs a Day

A newly developed propeller optimizer makes it much faster to identify propeller-hull reactions and reach design decisions. In the EU project STREAMLINE the fuel efficiency of a chemical tanker was improved by optimizing the hull form and propeller. To this end, MARIN used its hull optimization program PARNASSOS EXPLORER and a newly developed propeller optimizer. The hull form itself was optimized for low resistance and for having a wake field as rotationally symmetric as possible, while simultaneously maintaining the displacement and sufficient space for the engine room.

The Natural Order

The impact of increasingly stiff rules from legislators regarding ship engine emissions combined with ever increasing demands from ship and boat owners of better life-cycle performance and fuel economy has placed the onus squarely upon the diesel engine manufacturing community to continuously improve products and systems. While the diesel engine community has responded in kind with a variety of enhanced designs and concepts, there is a revolution spurred by evolution brewing in academia which promises to, at the very least, arm diesel engine makers with a system to quickly and cost effectively optimize current diesel engine performance, and to possibly even help to reshape the diesel engine's inner and outer appearance in the name of improving performance.