Gibdock Applies Graphene-based Fouling Release Coating

Gibraltar ship repair and conversion yard Gibdock said it recently hosted the Vulica Shipping Company-owned bulk carrier Donald M James for a 30-day project which brought a first opportunity to work with a new type of coating from GIT Coatings (Graphite Innovation & Technologies Inc).The 229-eterm-long ship entered Gibdock’s No.1 Dock for extensive works, including renewal to cargo holds, piping, thrusters, tail shafts and rudders. The yard also applied shipping’s first antifouling…

Tom Cruise Visits Aircraft Carrier USS George H.W. Bush

One of Hollywood's biggest stars recently paid a visit to U.S. Navy sailors aboard the Nimitz-class aircraft carrier USS George H.W. Bush (CVN 77).Top Gun: Maverick producer and star Tom Cruise was joined by writer and producer Christopher McQuarrie, and editor Eddie Hamilton, along with Ted Lasso star Hannah Waddingham, for the stop. The team led a Top Gun: Maverick viewing in the ship’s hangar bay and took time to visit with sailors aboard the ship, which has been deployed since departing Naval Station Norfolk in August 2022.“I know our sailors will never forget that night in the hangar bay…

Marine News' Top Vessels of 2022

The November edition of Marine News magazine highlighted the most notable newbuilds delivered in 2022. From sturdy and nimble workboats, to the first new Jones Act laker in a generation, each vessel on display showcases the industry’s engineering prowess and technological ingenuity, with the focus on improving efficiency in operations. The maritime industry has no shortage of challenges to overcome, and each of Marine News’ top vessels will, in one way or another, aid efforts to tackle them.Mark W.

Interlake Steamship Christens First New US-flagged Laker in Nearly 40 Years

The Interlake Steamship Company held a christening ceremony in Cleveland on Thursday for its new vessel, Mark W. Barker, the first U.S.-flagged freighter built on the Great lakes in nearly four decades.“This is truly a historic celebration for our company and for the United States maritime industry as we proudly christen the newest vessel to join the U.S. flag fleet on the Great Lakes and our first new build in 41 years,” said Mark W. Barker, President of The Interlake Steamship Company and the vessel’s namesake.

President Biden Instates Admiral Fagan in Historic USCG Change of Command

Adm. Karl L. Schultz was relieved as Commandant of the U.S. Coast Guard by Adm. Linda L. Fagan during a military change-of-command ceremony presided over by President Joseph R. Biden Jr., Wednesday, June 1, 2022, at Coast Guard Headquarters in Washington, DC. Fagan makes history not only as the first woman to lead the Coast Guard, but also as the first woman Service Chief of any U.S. military service.Immediately following the change-of-command, Schultz retired from the Coast Guard after 39 years of service to the nation.

Looking for a Good Deal? Learn to Take Advantage of Interns

For the future of the industry, hire interns, both college and high schoolers. And pay them: none of that silly privileged unpaid intern crap that occurs in non-maritime industries.I generally wait until I receive the printed issue to read Maritime Reporter and Engineering News, and when I read the August edition, I was both delighted and frustrated, mostly because of the two articles on shipbuilding workforce development.There is so much STEM wheel spinning and to see reports…

Everett Ship Repair Adds Two UHP Water Blasting Systems

Everett, Wash. ship repair yard Everett Ship Repair (ESR) said it has purchased two new 40,000psi ultra-high-pressure (UHP) water blasting systems. Both have been delivered to the shipyard and put into production.The new water blasting systems are capable of standard surface preparation and specialty applications, and allow ESR to deploy up to four water blasters simultaneously in a wide variety of applications including internal tank hydro blasting for cleaning and coatings removal.a cost effective and environmentally friendly alternative to abrasive solid blasting material…

Let’s Get One More National Multi Mission Vessel, but Let’s Add Some Grit

The new maritime academy school ships being built at Philly Shipyard (officially designated as National Security Multi-Mission Vessels) are an exciting development and provide a significant boost to our national maritime educational system. The technology on our existing school ships has very little relevance to the present marine industry, and these new vessels will not only provide the students with a better educational setting, in their multi-role deployment, they will also provide more exposure to maritime education.Maritime education is one of the country’s educational gold standards.

Ford Commences Second Round of Carrier Qualifications

USS Gerald R. Ford (CVN 78), the only carrier qualification (CQ) asset regularly available on the East Coast this year, commenced its second round of CQs for Fleet Replacement Squadron (FRS) pilots May 10, with a healthy and mission-focused crew.Ford, operating at-sea at the same time as four other U.S. aircraft carriers, is conducting its fourth independent steaming event (ISE) since commencing an 18-month Post Delivery Test and Trials (PDT&T) phase of operations in November…

Better Blasting: Send in the Robots

When designing and constructing a new blast and paint facility at its yard in Belle Chasse, La., C&C Marine and Repair set out to create a safe, efficient and environmentally friendly worksite that would deliver a high-quality product.Fifteen months and 131 barges later, C&C Marine has nearly doubled its capacity as the facility and its robotic blasting technology continually meet and exceed expectations, says Tony Cibilich, president and owner of C&C Marine and Repair, who sees a long list of benefits for customers…

Guam Shipyard Ordered to Control Pollution

The U.S. Environmental Protection Agency (EPA) has ordered Guam Shipyard to obtain a stormwater discharge permit and to achieve compliance with the Clean Water Act for discharges of pollutants into Apra Harbor, Guam.“Ship repair facilities must have stormwater pollution controls to protect coastal ecosystems,” said EPA Pacific Southwest Regional Administrator Mike Stoker. “This order will prevent pollution from reaching Apra Harbor.”Guam Shipyard operates a ship repair facility on Cabras Island in Piti, Guam. It has operated industrial activities, including boat repair, sandblasting, high pressure washing, painting and material storage since at least January 2016.EPA inspected the facility on September 2018 and found multiple violations of the Clean Water Act.

C&C Marine Celebrates 100th Barge Blasted

Just nine months after opening their new Robotic Paint and Blasting facility C&C Marine and Repair has announced the blasting of its 100th barge. “We knew we had the capability to blast and paint barges quickly and efficiently, but what we’ve been able to accomplish in these first nine months has exceeded our expectations in both speed and quality of blast” says C&C Marine and Repair’s owner, Tony Cibilich. The 83,350 square foot facility can accommodate barges up to 320’x75’ and has the capability to blast and paint a standard 30…

Shipyard Coatings: Green is the Best Color

VT Halter’s new state-of-the-art blast and paint facility, already paying dividends for the shipyard’s bottom line and the environment alike, is poised to lift your bottom line with improved coatings and reduced corrosion.When it comes to marine coatings, preparation is everything. If that’s the case, then Gulf Coast-based VT Halter has all the boxes checked when it come to making sure that every vessel component and exposed surface that leaves its facility is ready for whatever harsh conditions come next. That’s because, in April of 2018, VT Halter Marine unveiled a state-of-the-art blast and paint facility that today allow ship sections to be prepared, blasted and painted in a controlled environment.

The Top 10 Maritime Stories for 2018

Choosing the ‘top stories of 2018’ was, this year, a difficult task. Many compelling story threads played out, dramatically impacting the North American waterfront, and in particular, the workboat sector – each in their own unique way. Read on to find out how and why.Autonomous Vessels: Ready or Not, Here They ComeFuturistic, remote-controlled autonomous marine vehicles aren’t coming. They are here. As the pace of change quickens, autonomous vessels are already providing service and value on the water. Out ahead of the rulemaking process, autonomous technology providers already churn out not just prototypes and designs, but also countless workboats, many already in service.

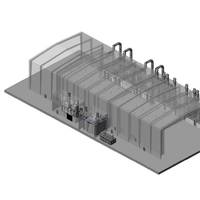

New Indoor Paint and Robotic Barge Blasting Facility

LA based C&C Marine and Repair has announced the opening of their new indoor, climate controlled, Paint and Blast Facility. The 83,350 square foot facility can accommodate barges up to 320’x75’x20’ and will be able to blast and paint a standard 30,000 Barrel Tank Barge or two 10,000 Barrel Tank Barges in 7-10 days. The fully enclosed, climate-controlled facility is unaffected by inclement weather and allows for uninterrupted operation year round. “We modified technology that was being used to blast rail cars and containers and have successfully adapted the process to blast barges…

Truman Strike Group Returns to Norfolk, Remains Ready

Nearly 6,500 Sailors of the Harry S. Truman Carrier Strike Group (HSTCSG) arrived in Naval Station (NS) Norfolk, Virginia, July 21.The aircraft carrier USS Harry S. Truman (CVN 75) and strike group ships USS Normandy (CG 60), USS Arleigh Burke (DDG 51) and USS Forrest Sherman (DDG 98) arrived after operating for more than three months in the U.S. 5th and 6th fleets areas of responsibility."I couldn't be more proud of this strike group team's performance over more than three months of operating in a highly-dynamic environment across two theaters," said HSTCSG Commander Rear Adm. Gene Black. "We carried out the full spectrum of missions…

VT Halter Opens New Paint Facility

VT Halter Marine Inc. has unveiled its new state-of-the-art blast and paint facility that will allow ship sections to be prepared, blasted and painted in a controlled environment. The ceremony included a keynote speech given by Senator Roger Wicker, U.S. Senator for the state of Mississippi.“The installation of this new blast and paint facility is to incorporate cutting-edge technologies in our marine construction programs. We are now able to apply a diverse range of protective coatings regardless of the weather conditions…

VT Halter Building New Blast and Paint Facility

VT Systems’ shipbuilding arm VT Halter Marine said it has begun construction of a new state of the art integrated blast and paint facility, effective April 17, 2017. The new facility at VT Halter’s Pascagoula, Miss. shipyard will allow the complete indoor and environmentally controlled surface preparation and final painting of ship sections prior to final erection. Its “flow-thru” configuration will allow ship sections to be prepared, blasted and painted complete without having to be taken outside and ensuring particles from the facility are not released into the environment.

China's Emerging Ship Repair Leader

Maritime Reporter & Engineering News interviews Chen Yong president Zhoushan IMC YongYue Shipyard Engineering Co., (IMC-YY) an emerging leader in ship repair and conversion in China. For our readers not familiar with IMC-YY, can you describe your physical facilities? Houshan IMC-Yougyue Shipyard & Engineering’s success starts with its physical facilities, which includes two graving docks (300,000 dwt, 350 x 65 x 13.6 m; and 100,000 dwt, 251 x 39 x 11.8m) and two sizable wharfs, one measuring 524.5m long with a 12-m depth, the second 250m long with a 12-m depth.

Sherwin-Williams Bags Steel Tank Institute Award

Sherwin-Williams Protective & Marine Coatings was awarded the Steel Tank Institute (STI) 2015 Affiliate New Product of the Year for its EnviroLastic Polyaspartic coatings at STI’s annual meeting in partnership with the Steel Plate Fabricators Association. The foundation of the EnviroLastic Polyaspartic product line is high-throughput applications for shops. These products were also designed to provide performance, durability, and ease of workability for applicators. Specifying these new technology coatings can provide improved levels of efficiency…

Pontoon Deck Preservation for Floating Dry Docks

Dry dock pontoon deck preservation is often taken for granted. In the flow of ever changing priorities for dry docks, it often gets pushed aside and/or delayed. If neglected long enough and often enough between preservation cycles, the thickness of the pontoon deck steel plates can be compromised. Salt water with chloride contamination causes accelerated corrosion while impact and abrasion damage from heavy equipment also take their toll. For shipyards, the overall objective should be to provide a protective surface that will hold up over time, and that is easy to clean.

SPS Deck Reinstatement for Canadian Fishing Vessel

IE has repaired the deck of a Ueushuk Fisheries Ltd owned fixed gear vessel, the Atlantic Optimist. The existing steelwork on board the vessel was badly corroded, access tight and a crop-and-replace repair was an unattractive option. When IE personnel arrived in Canada in mid-April, the 40msq of deck requiring steel reinstatement had already been grit blasted. Solid perimeter bars that form the boundary of the cavity and top plates were welded into place and the resulting cavity…

Ocean Endeavor Repair Completed

Harris Pye Engineering Group completed repair works during the two-stage multi-million dollar Diamond Offshore demobilization project for its semi-sub rig Ocean Endeavor from the Black Sea, which completed its contract in January 2016. The initial phase of the repair work, which started in December 2015, while the rig was offshore Constanta, Romania involved cleaning of mud, brine, base oil and skimmer tanks. Steel repairs were carried out on a main column blister. The removal of three Seatrax crane pedestals…