GTT LNG Carrier Orders at Record Highs

Gaztransport & Technigaz (GTT), a company specialised in the design of membrane containment systems for maritime transportation and storage of liquefied gas, said its business activity was marked by a number of successes during the first nine months of 2019, particularly in the field of LNG carriers.In addition to the 26 orders for LNG carriers booked during the first half of the year, there were an additional 14 bookings in the third quarter of 2019, i.e. a total of 40 LNG carrier orders during the first nine months of 2019.GTT's core business activity is, therefore, at a particularly high level. All of the carriers will be equipped with GTT's recent technologies (Mark III Flex+, Mark III Flex and NO96 GW).

Ballast-free LNG Carrier Concept Gets LR Approval

The maritime industry has taken a step closer toward ballast free shipping with the award of a new approval in principle (AiP) at Marintec China on Tuesday. GTT and Dalian Shipbuilding Industry Co. Ltd (DSIC) received AiP from Lloyd’s Register (LR) for their ballast-free shipping solution, a 30,000m³ B-FREE liquefied natural gas (LNG) carrier design, which the developers say could combine environmentally-friendly features, increased efficiency and lower build and operating costs. “While we are still in the initial stage of the project and the design is subject to ongoing change, the initial results are indicating that we will meet our goal of having a ballast-free ship that is equal to, or better than existing conventional designs,” said Ma Yingbin, Vice Chief Engineer, DSIC.

GTT to Equip Samsung-built FLNG

GTT said it has received an order from Samsung Heavy Industries (SHI) to equip a new Floating Liquefied Natural Gas unit (FLNG), reportedly the second biggest in the world. The new FLNG, with a capacity of 238,700 m3, will integrate eight LNG tanks equipped with the Mark III membrane containment system. The unit will be built at SHI Shipyard, based in South Korea, on behalf of the Oil and Gas company ENI (Eni East Africa SpA) and its delivery is scheduled in 2021. This FLNG will be operated off the cost of Mozambique. In addition to this new order, the GTT membrane technology has been selected to equip the three FLNGs already ordered in the world. These units are being equipped with the NO96 system as well as the Mark III system.

Reliance Inaugurates New Ethane Carriers

In a ceremony held in Geoje (South Korea), Indian's largest private sector company Reliance Industries Limited (Reliance) inaugurated its very first two VLEC (Very Large Ethane Carrier), in the presence of the shipyard Samsung Heavy Industries (SHI) and other key partners of the project. These vessels, Ethane Crystal and Ethane Emerald, are the world's first ethane carriers to feature GTT's membrane technology. They are the first of a series of six vessels, ordered by Reliance in 2014, which will be fitted with GTT's membrane containment systems. With a capacity of 87,000 m³, these two vessels are the largest VLEC ever built to date. They will be used to transport liquid ethane from the United States to India.

Matrix PDM Signs Licensing Deal with GTT

GTT's Houston-based US subsidiary, GTT North America (GTT NA), has signed a license agreement with the American engineering company Matrix PDM Engineering. The agreement was signed at the Matrix Service Company headquarters in Tulsa, OK, in the presence of John Hewitt – Matrix Service Company CEO, Joe Montalbano – Matrix Service Company COO and Matrix PDM Engineering President; and Aziz Bamik – General Manager, GTT NA. The license grants Matrix PDM Engineering the right to implement GTT’s patents to construct onshore storage tanks for LNG (liquefied natural gas), LPG (liquefied petroleum gas) and other liquefied gases through affiliated Matrix construction companies.

Solving the LNG Propulsion Puzzle

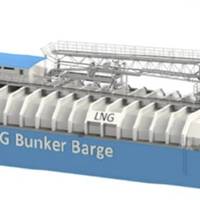

The last piece of the LNG infrastructure puzzle, in the form of North America’s first LNG bunker barge, falls into place at Conrad’s Orange, Texas Shipyard. With continued debate over new emissions standards and compliance dates hanging over the heads of operators in the Emission Compliance Zones like the Sword of Damocles, WesPac Midstream LLC, a provider of liquefied natural gas solutions, and its affiliate Clean Marine Energy, a facilitator of solutions for emission compliance…

WesPac to Build N. America’s First LNG Bunker Barge

WesPac Midstream LLC (WesPac), a provider of energy infrastructure and liquefied natural gas (LNG) solutions, and its affiliate Clean Marine Energy LLC (CME), the global facilitator of tailored solutions for Emission Control Area (ECA) compliance, announced a construction contract with Conrad Orange Shipyard, Inc., a division of Conrad Shipyard, LLC, to build the first dedicated LNG bunker barge for the marine market in North America. This barge will be a critical supply chain…

GTT Records First Bunkering Order

GTT technology has been chosen by STX France to equip PEGASIS, the new environmental vessel ordered by Brittany Ferries. GTT membrane technology has been selected by STX France to fit out PEGASIS (Power Efficient GAS Innovative Ship), the new environmental ferry propelled with LNG (Liquefied Natural Gas), ordered by Brittany Ferries. This innovative vessel will use GTT Mark III insulation system and will be built in Saint-Nazaire, in France. It should be delivered by the end of 2016. In addition, GTT has also been selected to design the tanks of three other Brittany Ferries ships to be converted to LNG propulsion. This order has arrived within the context of new European regulations…