When Efficiency Does Not Help Sustainability

My brother and I had a discussion about methanol where we concluded that methanol is a promising sustainable liquid fuel for transportation devices when batteries cannot do the job. While Methanol is initially not carbon zero, as long as we focus on developing zero carbon electrical energy, eventually we can produce zero carbon green methanol. Once there is plentiful green methanol, existing methanol vehicles will automatically become zero carbon transportation.The core argument…

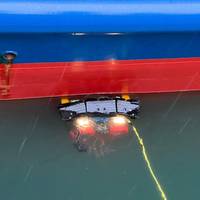

Armach Robotics Set to Take the Pole Position on Ship Hull Maintenance, Intelligence

Melding advanced software, intelligence, robotics and navigation, Armach Robotics – a spinoff of Greensea Systems – leads a step change in ship hull cleaning and maintenance with its Robotics as a Service model. Ben Kinnaman, the CEO of Greensea Systems, explains.Ben, to start us off, please give us a background on Armach Robotics? Where did the idea come from and where are we today?Greensea Systems is a software company, well-known for our software platform on ocean robotics. We're also well-known for our unique navigation and autonomy solutions.

Polsteam, Nova Ship Tech SA Select Alfa Laval PureBallast 3

Alfa Laval said it has signed fleet agreements with Polsteam and Nova Ship Tech SA for the supply of PureBallast 3, the third generation of Alfa Laval’s ballast water treatment technology.Under the agreements, Alfa Laval will provide dozens of Polsteam and Nova Ship Tech SA vessels with PureBallast 3 systems – the vast majority of which will handle large flows of more than 1,000 m3/h.The agreements with Polsteam and Nova Ship Tech SA come as many ship owners shift their focus from individual ballast water treatment systems to complete fleet solutions.

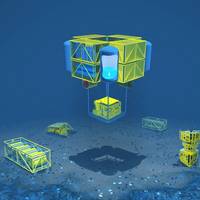

MUM's the Word: New UUV Takes Shape in Germany

The Large Modifiable Underwater Mothership (MUM) brings German engineering prowess and cooperation to the fore. As the world of autonomous vehicles flourishes on land and in the air, subsea applications have proven more challenging, despite great strides in recent years to deliver fully autonomous, efficient systems at sea. A team of engineers from Germany, engineers teamed from industry and academia, are aiming to drive the subsea vehicle market further faster courtesy of a project known as the Large Modifiable Underwater Mothership, or MUM.

Bergen Subsea Cluster Poised for Business

The Hanseatic trading city of Bergen, on the edge of the Norwegian North Sea, has a long maritime tradition. From shipping to aquaculture to offshore oil and gas, this is a city whose economic identity is defined by its ties to the sea. The city is by far Norway´s largest port, with more than 13 million metric tonnes of cargo transported to and from Bergen in 2010. Bergen is also the country´s largest center for aquaculture and marine science research, and is home to the Institute of Marine Research and an active marine science research centre at the University of Bergen.

The Lure of the Electric Drive

By Stuart C. Karon and Dr. In the September 2002 issue of Maritime Reporter and Engineering News, a detailed discussion was featured on the advantages of future High Temperature Superconductor (HTS) machinery for propulsion of electric drive ships. • Motors A 5-MW 230-rpm machine for the U.S. Navy's Office of Naval Research (ONR) is undergoing factory tests. ONR is now funding the next step - design, fabrication and factory testing of a 36.5-MW 120-rpm machine to prove the technology at full-scale for warships. • Generators Development of HTS generators has also leapt ahead with the initial production of 10-MVAR synchronous condensers for utility voltage adjusting service. These condensers are very similar in design and operation to 10-MW, 1,800-rpm generators.

65th Anniversary: From 2D CAD to the Integrated Product Model

One of the most important improvements in ship production has been the introduction of CAD/CAM. The initial use of computers for drafting, lofting and automation of steel cutting has been extended from the design office and the mold loft throughout the shipyard and beyond by integrating the Internet, sophisticated database applications and enterprise management software to radically improve the entire shipbuilding process. However, the result of this, the Integrated Ship Product Model, is poised to revolutionize ship management and maintenance throughout its lifecycle. Boats and ships differ from most other objects because they are formed of arbitrary curved surfaces instead of well-defined assemblies of geometric shapes.