Mawai Shipyard Building New Multipurpose Carriers for COSCO

China''s Mawai Shipyard has started building the first in a series of 22 new multipurpose cargo carriers for COSCO Shipping Specialized Carriers (Southeast Asia) Pte. Ltd.The 85,000 DWT series vessel will measure 225 meters long with a breadth of 36 meters, a depth of 21.05 meters, a designed draft of 10 meters, and a designed speed of 15.5 knots.According to the construction plan, all 22 vessels in this series are scheduled for delivery between 2025 and 2026.The ships will primarily serve the export of Chinese manufacturing equipment in sectors such as automobiles…

Fearing China, South Korea Targets Contractors on Taiwan Navy Submarines

South Korean authorities cited the risk of Chinese economic retaliation when they charged marine technology firm SI Innotec last year with violating trade laws for its work on Taiwan's new military submarine program, according to a police document seen by Reuters and two people familiar with the matter.In a Feb. 17, 2022, affidavit to a judge seeking the arrest of SI Innotec executive director Park Mal-sik, police said authorities feared a repeat of the sweeping sanctions imposed by Beijing in 2016, after Seoul decided to install THAAD, a U.S. anti-missile system.

3D Printing: Navy Builds Up Additive Manufacturing on Ships

The U.S. Navy has long valued the potential of additive manufacturing (AM) and 3D Printing.AM refers to the depositing of material layer by layer to create an object. For the Navy, it’s not practical to carry every replacement part for every system on a ship, and it can be difficult to forecast if or when parts will fail. AM provides a flexible source of supply in being able to make parts instead of ordering them and waiting for them to arrive, especially for warships at the far end of the supply chain.

US Navy Taps GA-EMS to Study Propulsor Bearing Concept Designs

General Atomics Electromagnetic Systems (GA-EMS) said on Friday it has been awarded a task order from Naval Surface Warfare Center, Carderock Division (NSWCCD) to conduct a manufacturing assessment of several new propulsor bearing concept designs for U.S. Navy submarines. The task order is under the Propulsor Demonstration Hardware (PDH) Indefinite Delivery, Indefinite Quantity (IDIQ) contract previously awarded to GA-EMS.“Manufacturing feasibility evaluations such as this are crucial steps in determining whether a new concept design will deliver greater performance…

MARAD Announces Nearly $20 Million for US Small Shipyards

The U.S. Department of Transportation’s Maritime Administration (MARAD) recently announced the availability of nearly $20 million in Fiscal Year 2022 Federal funding to support funding to help modernize U.S.'s small shipyards.MARAD’s Small Shipyard Grant Program aims to strengthen the economic competitiveness of shipyards by providing grants that can be used to purchase equipment or train employees. In addition, the purchase of American-made manufacturing equipment with these, small shipyard grants support a wide range of jobs throughout our nation’s manufacturing base.

MARAD Awards $20 Million in Shipyard Grants

The U.S. Department of Transportation’s Maritime Administration (MARAD) on Monday awarded $19.6 million in grants aiming to help 31 shipyards modernize, increase productivity, and expand local employment opportunities while competing in the global marketplace.The grants were awarded to shipbuilding and repair yards in 15 states throughout the U.S. as part of MARAD's Small Shipyard Grant Program. Since 2008, the program has awarded $262.5 million to nearly 300 shipyards in 32 states and territories.

Tech File: Naval Postgraduate School Adds Xerox ElemX 3D Printer

The Navy is a step closer to achieving the vision of being able to fabricate parts on demand. Xerox and the Naval Postgraduate School (NPS) have announced a strategic research collaboration to advance 3D printing and additive manufacturing.As part of a Collaborative Research and Development Agreement (CRADA) between NPS and Xerox, a Xerox ElemX Liquid Metal Printer has been installed at the school’s Large Experiment Annex on campus. NPS is the first site anywhere in the world to install this new technology.“From the age of sail to the nuclear era…

Naval Postgraduate School adds Xerox ElemX 3D Printer

The Navy is a step closer to achieving the vision of being able to fabricate parts on demand. Xerox and the Naval Postgraduate School (NPS) have announced a strategic research collaboration to advance 3D printing and additive manufacturing.As part of a Collaborative Research and Development Agreement (CRADA) between NPS and Xerox, a Xerox ElemX Liquid Metal Printer has been installed at the school’s Large Experiment Annex on campus. NPS is the first site anywhere in the world to install this new technology.“From the age of sail to the nuclear era…

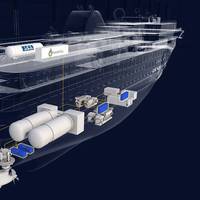

Prototype for Hydrogen - One Step Closer

Havyard is taking the next step towards a hydrogen system pilot for large ships. The company is entering the approval phase and has signed agreements with suppliers of hydrogen tanks and fuel cells.If large vessels are to sail zero emission at high speed over long distances, battery solutions does not contain enough energy. Fuel cells running on hydrogen is a solution to this, and the Havyard Group, with Havyard Design & Solutions and Norwegian Electric Systems, is now conducting…

Kirby Posts 2019 Q1 Results

Kirby Corporation announced net earnings attributable to Kirby for the first quarter ended March 31, 2019 of $44.3 million, or $0.74 per share, compared with earnings of $32.5 million, or $0.54 per share, for the 2018 first quarter. Excluding certain one-time charges, 2018 first quarter net earnings attributable to Kirby were $37.9 million, or $0.63 per share. Consolidated revenues for the 2019 first quarter were $744.6 million compared with $741.7 million reported for the 2018 first quarter.David Grzebinski…

Shipyard in Focus: Conrad Shipyard

Parker Conrad, a shipbuilding pioneer and a legend along the Gulf of Mexico coast and beyond, founded Conrad Shipyard in 1948. The company, headquartered in Morgan City, Louisiana, is now a public company with new generations of Conrad’s at the helm. “I grew up in the shipyard working side by side with my father,” said Johnny Conrad, President, Chairman and CEO explains. “I saw firsthand how he treated customers, and how his handshake was as good as a contract. Many of our current customers did business with Parker…

Ingalls Shipbuilding Acquires Automated Welding Solution

Pemamek Ltd. is delivering high-tech PEMA welding automation to Mississippi-based Ingalls Shipbuilding’s Pascagoula shipyard. The extensive and technologically advanced automation solutions provide Ingalls improved panel production and enhanced work flow. Mississippi-based Ingalls Shipbuilding, a subsidiary of the Huntington Ingalls Industries, kicked off its “Shipyard of the Future” initiative in 2014. The multiyear initiative includes investments in modern infrastructure and manufacturing equipment, as well as technologically advanced procedure and processes.

Conrad Awarded 9-Barge Build Contract

Conrad Shipyard said it has been awarded a contract to build four anchor barges, two deck barges and three crane varges for Great Lakes Dredge & Dock Company LLC (GLDD), headquartered in Oak Brook, Ill. The four anchor barges will be built in Louisiana at Conrad’s Morgan City Shipyard, and the deck and crane barges will be built at its shipyard in Orange, Texas. Conrad Senior Vice President and Director Dan Conrad made the announcement: “We have delivered seven vessels to GLDD since 2003,” he said.

Nautican to Ship First IPU from Prince Edward Island

The Nautican Research and Development manufacturing facility in Summerside, Prince Edward Island, said it is now ready to ship the facility's first Integrated Propulsion Unit (IPU) to a client in Alaska. “Nautican is another excellent example of an emerging advanced marine technology company finding success right here on Prince Edward Island,” said PEI Minister of Economic Development and Tourism, Heath MacDonald, who was on site with Nautican representatives to review the Ocean Series Class 200 IPU system prior to shipment.

Another Busy Winter for Fincantieri Bay Shipbuilding

The winter repair season is in full swing at Fincantieri Bay Shipbuilding (FBS) in Sturgeon Bay, Wis., where 16 vessels of various sizes from the Great Lakes bulk carrier fleet are in for winter repair, including five 1,000-foot bulk carriers, eight medium sized ships 600-700 feet long and three tugs. The scope of the repairs is as wide as the variety of ships at dock and include vessel repowering from steam propulsion to diesel, steel and piping repairs, bulkhead renewals, machinery inspection and repairs, exhaust scrubber installation, painting and regulatory inspections.

Delta ‘T’ Systems Expands Production

Marine ventilation systems company Delta “T” Systems said it has reconfigured its two 15,000 sq. ft. manufacturing spaces and added tooling and related equipment. The change accommodates the timely construction of the company's new USCG approved A60 Slimline Fire Damper and streamlines the production of the rest of its product lines. According to Delta “T” Systems, the new manufacturing equipment, plus other upgrades throughout the buildings, enhance its efficiency within all of its departments.

MN100: Conrad Shipyard

Conrad Shipyard was established in 1948 and is headquartered in Morgan City, Louisiana. The company designs, builds and overhauls tugboats, ferries, liftboats, barges, offshore supply vessels and other steel and aluminum products for both commercial and government markets. The company provides both repair and new construction services at its five Gulf Coast shipyards located in southern Louisiana and Texas. Widely recognized for innovation, Conrad has a separate business unit devoted to the construction…

Mercury Marine Expands Manufacturing Capacity

Mercury Marine is adding a 53,000 square foot manufacturing capacity expansion to its global headquarters in Fond du Lac, Wisc. The expansion will consist of 45,000 square feet of manufacturing capacity and an additional 8,000 square feet of office space. In addition, Mercury is investing in state-of-the-art manufacturing equipment to better streamline the manufacturing process and meet the growing demands in the marketplace. The new space will be completed in January, 2017. “This is an exciting time for Mercury Marine,” said John Pfeifer, Mercury Marine president.

Marinette Marine Completes $74 Million Shipyard Improvements

On Monday, May 20, Marinette Marine Corporation (MMC) of Fincantieri Marine Group, held a ribbon cutting ceremony to commemorate the opening of the company’s newest facility and to mark the completion of Fincantieri’s $74 million investment in the shipyard. Chuck Goddard, President and CEO of Marinette Marine, welcomed employees, Navy and Coast Guard representatives, government officials, and local community members to today’s event. Since 2009, MMC has doubled its indoor production space and increased its workforce by 60 percent, for a total of 1,400 employees. The shipyard, with purpose designed facilities, has utilized superior engineering and cutting edge technology to maximize production efficiency and minimize energy consumption.

Ocean Equipment debuts NavPods Gen3

Ocean Equipment, manufacturer of high-quality waterproof housings for marine electronics, announced today the completion of its newly redesigned and retooled NavPods for the 2016 model year. The NavPods represent the culmination of a period of substantial investment by Ocean Equipment and development of a new manufacturing facility equipped with the latest CAD/CAM design software, CNC routers, a full complement of thermoforming manufacturing equipment and a talented engineering team, following a relocation to Oregon. “We are committed to the NavPod brand and offer pre-cut NavPods for all the popular marine electronics manufacturers’ displays,” said Rob Walsh, president and owner, Ocean Equipment.

Cargo Morphs in New Directions

After a decline during the recession years, U.S. exporters today are pleased with the record-breaking value of overseas shipments. At the same time, they are learning to cope with shipping cargo that can be far different than the types of goods sold in the past. Looking back just a few years, exporters could often count on freight that was neatly contained and relatively impervious to long journeys. Today, they may be faced with goods that require special handling, or cargo with distinctive characteristics that must be taken into account during transit. Getting cargo from ‘Point A to Point B’s has never been more challenging – and shippers who are caught unprepared may see loss claims soar and their business reputation damaged.

DOD / U.S. Navy Contracts Awarded

Huntington Ingalls and Electric Boat Win multi-million dollar contracts. Huntington Ingalls, Inc., Pascagoula, Miss., is being awarded a not-to-exceed $70,000,000 cost-plus-fixed-fee modification to previously awarded contract (N00024-06-C-2222) for advance procurement of long-lead-time materials in support of LPD 27, the 11th ship in the San Antonio (LPD 17) class. Work will be performed in Pascagoula, Miss., and is expected to be completed by April 2012. Contract funds will not expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity. Electric Boat Corp., Groton, Conn.…

Multi-mission, Dual Design, Single Focus Littoral Combat Ships

Last month marked the launch of two new Littoral Combat Ships: Milwaukee (LCS 5) launched by Marinette Marine into the icy Menominee River; and Jackson (LCS 6) launched by Austal into the far warmer waters found off of southern Alabama. While the two LCS variants and shipyard climates are a world apart, this innovate U.S. Navy ship production program has the common goal of fortifying U.S. defense interests while spurring investment in the creation of two state-of-the-art ship production facilities. Mid-December in Marinette, Wis., can be described with one word: cold.