Design & Operation: Wind Farm Support Vessels

Offshore wind farm development has been led globally by the UK, followed by Germany. Both countries have governments with long term commitments to renewable energy. Denmark, Belgium and The Netherlands are building wind farms, but they are a long way behind the leaders in offshore wind. In 2014 the UK accounted for over 50% of all the offshore wind energy generated globally. All of these countries border the North Sea, a notoriously stormy sea area, which has a high frequency of wind to drive the turbines. Traditional survey vessels are first to arrive in a potential wind farm area.

Offshore Renewable Energy: Servicing North Sea Wind Turbines

A boat with suspension, a giant robotic arm and a vessel resembling a seahorse are just three of the innovative concepts shortlisted by the Carbon Trust as part of a competition to solve the problem of transferring engineers and equipment safely on to wind turbines as far as 300km offshore in wave heights up to around three meters. The project aims to improve the economics of offshore wind by keeping turbines generating electricity in the harshest sea conditions to increase revenues by as much as £3bn for the next generation of the UK’s offshore wind farms.

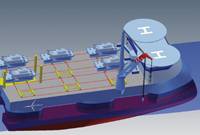

Voith Turbo Shuttle Fitted with Robot

Voith Turbo Marine Engineering has developed the Voith Offshore Shuttle for wind parks. Installed in the shuttle’s bow is the new MOTS (Momac Offshore Transport System), whose swivel-arm robot was designed to transfer people and goods from vessel to vessel, or from vessel to offshore wind energy plant. Voith Turbo Marine constructed the shuttle in cooperation with Momac, a machine builder that manufactures special purpose machinery, including robot-assisted transfer systems. The Voith Offshore Shuttle’s robot has been fitted with a transport basket with a maximum capacity of 250 kg, and the system was designed to compensate vertical differential movements of up to 3.2 m. Voith’s shuttle also features a Voith Inline Thruster in the bow and two Voith Schneider Propellers in the stern.