Is Stern Tube Damage Declining?

It might be easy to blame EALs, but the ongoing causes of stern tube damage are varied, and possibly declining.Environmentally Acceptable lubricants (EALs) gained market traction with the introduction of US VGP regulations in 2013. Since then, DNV has observed two major trends. The first, starting in 2013 was early life damage, either during sea trials or within the first five years of operation, where aft stern tube bearings typically failed under extreme load conditions. Then from around 2018…

Steeprop to Ferry Owners: Focus on TCO Instead of kW-power to Optimize Costs

Companies planning a new ferry build should focus on the Total Cost of Ownership (TCO) instead of kW-power, in order to optimize costs, Steeprop, a designer and manufacturer of azimuth propulsion systems, said.Choosing the propulsion unit based mainly on Capex, for example, will most likely increase costs in the long run, adding that a ferry owner can save more than two million euros over a 15-year period by concentrating on the TCO."The traditional way of handling the procurement of propulsion systems…

Offshore Equipment Hydraulic Maintenance Tip-of-the-Day: Oil Temperature

Tip #4: Oil Temperature - Assume that "running hot" is normalDuring warm summer months, with reasonable certainty, high machine temperatures will follow. This is especially true if using air oil heat exchangers. Dismissing this expectation may allow operators to prevent down time, as heat generation is a leading indicator of a failing part. Knowing how to recognize the difference can be the difference between reactive and preventative maintenance.Learn more about the importance…

New VEM Technology Leads for Royston

Diesel power specialist Royston said it will showcase new developments for 2018, including Vessel Energy Monitoring (VEM), at the International Workboat Show.VEM technology, which provides information about a vessel’s architecture and energy levels, as well as efficiency improvement recommendations, is part of Royston’s enginei product, which delivers cost savings and operational efficiencies for offshore vessel and workboat operators.The system records fuel consumption data from bunkers and individual engines, with data provided onboard and onshore.

ZF Condition Monitoring Optimizes Operations

Monitoring current data from the driveline as well as the status of core components makes it possible to avoid failures and plan maintenance work effectively. This shortens downtime, lowers operating costs and increases safety on board and at the port, says ZF, who offers detailed status monitoring for marine propulsion systems.As specialist for marine propulsion systems, ZF can help shipyards, shipping lines and fleet operators manage their ships more efficiently and safely with its condition monitoring system (CMS).

Maritime Thought Leadership: Christopher J. Wiernicki, ABS

The maritime industry has been challenged, to say the least. Today, where do you see challenge? Where do you see opportunity?It’s clear our business environment continues to change and we have a new definition of what normal means: nothing is normal. We are in era of rapid, disruptive and impactful change.The coming years will bring further turbulence, shaking out our industry and setting the course for the next 20 years and beyond. Market cycles will continue to evolve and will be impacted differently than they are today.For example…

Engine Providers Power Operators' Profits

With an eye towards environmental compliance, operational efficiencies and the bottom line, the Marine News top propulsion providers touch all bases. Sitting down to select the best engine and propulsion manufacturers in the workboat marine space isn’t necessarily the easiest task in the world. Nor is it a linear exercise. On the other hand, these Marine News featured firms – Caterpillar Marine, Volvo Penta and Yanmar – all have more in common than you might think. With a laser focus on their collective customer’s bottom lines and addressing that concern through technology, environmental compliance and economical but powerful performance, each satisfies the niche in its own particular fashion. See if you don’t agree.

YANMAR's New EPA Compliant Commercial Engine

Installed and on the water, Yanmar’s 6AYA-ET engines are already providing value on the U.S. Gulf Coast. This fully mechanical engine is anything but low-tech. More than 60 years of worldwide experience plus an engine designed specifically for the United States market has made a winning combination for YANMAR’s new EPA compliant commercial engine application. The Push boat Sherry L, owned by E Squared Marine Services, LLC from Texas and repowered by Laborde Products, now operates even more quietly and with better fuel consumption thanks to its new 6AYAM-ET engines. That’s only part of the story, however. With a need for 24 hours of continuous operation each day pushing inland barges from Channelview to Galveston and on Gulf intercoastal waterways…

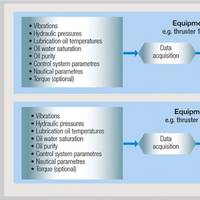

Wärtsilä Expands Propulsion Monitoring Services

Wärtsilä expanded its offering in propulsion monitoring services. The Wärtsilä Propulsion Condition Monitoring Service (PCMS), introduced to the market in 2010, will now feature expanded functionalities and is now available in two editions - PCMS Starter and PCMS Professional. The need for certainty of operations and long-term maintenance planning is fulfilled with a new functionality - Dynamic Lifetime Prognosis (DLP). Wärtsilä Propulsion Condition Monitoring Service is a solution for monitoring propulsion equipment.

MacGregor Launches Steering Alert System

MacGregor, part of Cargotec, has launched Soteria, a new alert system designed to complement its Hatlapa and Porsgrunn range of steering gear. Named after the Greek goddess of safety, the system has been designed to offer a series of benefits for both ship owners and shipyards. “The system’s alert display can be fully integrated on the vessel’s bridge, ensuring clear and easy access to a comprehensive range of alerts,” explained Henrik Schädel, Hatlapa Drives & Controls expert at MacGregor. “The system has been designed for simple, economical installation and requires only one programmable logic controller (PLC), a feature which benefits shipyards," Schädel notes.

The ABCs of EALs for the EPA’s VGP

When the Environmental Protection Agency (EPA) issued the new Vessel General Permit (VGP) in December 2013, lubricant and fluid manufacturers were prepared to give vessel owners a number of environmentally acceptable lubricants (EAL) to work with. EAL usage is now essentially required for any application on vessels where incidental lubricant discharge could occur in the marine environment. Those applications include stern tubes, thrusters, stabilizers, CPP propellers, and wire rope and mechanical equipment immersed in water during normal operation.

Good News Comes in Threes

Caterpillar, Wärtsilä and Volvo Penta introduce new, efficient and environmentally compliant engines. A crowded market becomes even more competitive. Forget all the worries about how industry would be able to comply with the coming changes to the regulatory scheme that affects marine propulsion and related emissions. Demand has met supply and it has done so robustly and in impressive form. And, if the past month is any indication, the innovation in the market is more than keeping up. This month, we provide just a sampling of the impressive developments in marine propulsion. Clearly, workboat operators now have a cornucopia of options for the repower and newbuild market, alike.

New STAUFF Mini Water Vac Cleans Oil Continuously

The STAUFFMini Water Vacpurifies hydraulic system oil, eliminating water, gas and particulate matter. The purified oil satisfies the most stringent quality requirements. The STAUFFMini Water Vac dehydrates and cleans most types of oils such as lubricating, hydraulic, transformer and switch oils while it neither removes nor alters oil additives. The water removal process is based on pure vacuum evaporation inside a vacuum chamber at a maximum temperature of +65 °C / +149 °F. Solid particle removal is achieved through a field-proven STAUFF Systems Micro Filter.

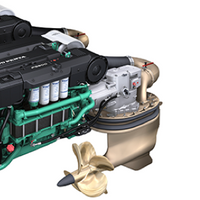

Volvo Penta Unveil New IPS 900

Volvo Penta now launches its IPS900 propulsiion system making it suitable for boats in the Coast Guard & Patrol, Supply Vessels, & Offshore Energy & Passenger Transport segments, as well as yachts. Volvo Penta IPS is the modern inboard system, superior to inboard shafts in every vital aspect – handling, onboard comfort and performance. Those benefits have made Volvo Penta IPS the by far most popular pod system for leisure boats. With the Volvo Penta IPS, the customer gets a complete drivetrain from one single supplier who takes responsibility for everything from helm to prop…

Increased IPS Range for Marine Commercial

Volvo Penta is now launching IPS900 with Rating 3 for commercial boats, which they say means a larger number of boats for commercial use can take advantage of the well-known IPS benefits: improved fuel economy, better maneuverability and lower overall operating costs. With the launch of Volvo Penta IPS900, the Inboard Performance System (IPS) is now available for boats in the Coast Guard and Patrol, Supply Vessels and Offshore Energy and Passenger Transport segments. This means great handling and operational benefits for boats used by…

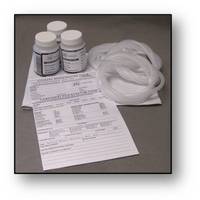

Oils and Oil Analysis: What You Need to Know

In any given lubricant (such as engine oil, transmission fluid or gear oil), there are three main factors that influence the “useful life” of the lubricant: Viscosity Stability, Oxidation, and Contamination. While it is important to understand how these factors affect oil life, it is equally important to realize that none of these factors can be measured or monitored except through a thorough and ongoing oil analysis program. Viscosity - First, let’s examine the oil property known as “Viscosity.” Viscosity is defined as resistance of an oil to flow at a given temperature.

ZF: Information for Vessels in Oil Affected Waters

ZF Marine, in recognition of the large number of vessels operating in support of the oil containment and clean up efforts in the Gulf of Mexico, offers the following information to fleets operating ZF Marine transmissions with raw water cooling systems. ZF Marine understands that operation of the vessels in these waters cannot be avoided. As such, Chief Engineers, and Port Captains should consider taking the following actions to maximize transmission cooler life. 1. Adhere to the cooler cleaning regimen outlined in the operator’s service manual. 2. Transmissions not equipped with an oil temperature monitoring system should have it installed as soon as possible.

New Navy Contracts

Raytheon Co., Tucson, Ariz., is being awarded a $151,577,441 modification to previously awarded contract (N00024-07-C-5431) to procure 186 Evolved SEASPARROW Missiles (ESSM), 77 shipping containers, and spares for the NATO SEASPARROW Consortium and the United Arab Emirates. Work will be performed in Tucson, Ariz., (45 percent); Camden, Ark., (2 percent); Andover, Mass,. (10 percent), Australia, (11 percent), Canada, (7 percent), Denmark, (1 percent), Greece, (1 percent), Germany, (8 percent), The Netherlands, (6 percent); Norway, (5 percent); Spain, (3 percent); and Turkey, (1 percent), and is expected to be completed by August 2012. Contract funds will not expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity.

Oil Recovery Project Makes Progress

The U.S. Coast Guard’s Marine Safety Office San Francisco Bay, the California Department of Fish and Game Office of Spill Prevention and Response (OSPR) and Titan Maritime, Inc. continue their steady progress on the assessment and oil removal operations from the sunken 468 ft. cargo ship S.S. Jacob Luckenbach , which sank 50 years ago, 17 miles West of San Francisco. Despite the challenges and risks involved with the operation, the responders have identified 26 tanks and spaces on the wreck containing about 132,000 gallons of heavy fuel oil. To date, about 12,000 gallons of oil have been recovered. During the assessment, many fuel tanks were found to have badly corroded vent pipes which allowed oil to slowly leak into the cargo holds.

FEATURE: The Computer Invades the Pilothouse

Shipboard monitoring, sensing and control systems are in a transitional phase in 2002. Many of the newest vessels being launched today are using traditional monitoring systems with large alarm panels using banks of warning lights hard wired to 64 or more critical points on the vessel. These systems give warning if the system being monitoring falls or rises outside of the set point. "The problem is this method of monitoring doesn't give us the parameters the operator needs to diagnose the problem," said Jack Rowley, general manager of Engine Monitor, Inc., (EMI) St. Rose, La., a leading manufacturer of electronic ship monitoring equipment.

Garland Introduces The Master Series

Garland has presented its master series - a select group of its finest ranges, broilers and fryers. The series offers a new level of speed, comfort and control, beginning with its Starfire 35K burner, which reduces preheat times and provides greater heat input for cooking in large-sized vessels. Ranges are available with storage; standard and convection oven bases; and can be used in stand-alone, multiunit and battery applications. Master Series charbroilers are suited for both production line and a la carte broiling. Six powerful burners and long-life ceramic briquettes generate 90K BTUs of heat for even heat distribution and shorter cooking times. Designed for high-volume use, Master Series fryers quickly drive off water and steam.

Marine Software: What’s New?

There are a number of computer programs and hardware that promises to make marine vessels more productive and interactive. For example, Maxsea, Marstons Mill, Mass. has a module that connects their chart plotter to the sensors of a dredge to record the vessel's track. The track can be displayed on the chart plotter and the data collected can be directly exported in the ASC II format for use by other data processing software. The seabed outline is displayed "live" in 2-D and 3-D and the data is recorded. Need a tough bulkhead-mounted PC? Comark of Medfield, Mass. has a unit with the enclosure made of marine aluminum with an epoxy powder finish and is rated for a Nema 12 environment.

MICAD Marine, France Helices Announce Partnership

MICAD Marine has formed a partnership with France Helices to offer vessel operators condition-based maintenance monitoring on the NEW Surface Drive System. The NEW Surface Drive System will utilize MICAD Marine's Real Time Monitoring System to continuously monitor the vibration, oil temperature and bearing temperature occurring on the vessel. These real time readings are then compared to the established set of indices, or Vessel Signature, to determine if an abnormal condition exists. If an abnormal condition is present, the MICAD Marine System is designed to trigger an alarm to alert operators that corrective action is required. These condition-based alarms help to ensure that maintenance is performed on-time well in advance of costly surprise failures.