The "KISS Principle" & Managing, Measuring Ship Emissions

HydroComp is a well-established, small engineering firm focused on hydrodynamic and propulsion system simulation, providing design tools for engineers and naval architects to focus on vessel performance, including emissions. Don MacPherson, HydroComp’s long-tenured Technical Director, discusses the impacts of tightening emissions regulations, with insights on maximizing new vessel designs and refits.Don, maritime has been in the crosshairs of regulators to reduce emissions. What do you see as the top new regulatory issues that are impacting ship and boat design…

A BC Ferries Case Study: Lessons Learned in Setting Underwater Radiated Noise Targets

In a typical year, the waters surrounding British Columbia’s Port of Vancouver host approximately 3,000 deep sea commercial vessels and 19 of the 35 ferries operated by BC Ferries, one of the largest ferry operators in the world. These waters are also home to a wide variety of aquatic wildlife, including the southern resident killer whales (SRKW), which have been listed as endangered in Canada since 2003.With vessel-generated acoustic disturbances identified by Fisheries and Oceans Canada as one of four key threats to the SRKW…

BAE Systems Orders Propeller Blade from VEEM for Hunter Class Frigates

Australia-based VEEM, a company designing and building marine propulsion and stabilization systems, will manufacture a pilot propeller blade for the Hunter Class Frigate Program (HCFP), under a contract awarded by BAE Systems Maritime Australia."The order enables VEEM to demonstrate it has the manufacturing capability to join the HCFP supply chain. As a world leader in premium commercial propellers that has delivered similar blades to defense clients globally, VEEM is very confident it can meet the requirements of the HCFP…

Underwater Propeller Repairs in Winter Conditions in Europe

In just over a week Hydrex diver/technicians traveled to Finland, Germany, the Netherlands and France to assist shipowners with damaged propeller blades. On two bulkers the blades were cropped while on a third bulker and a general cargo vessel the bent blades could be straightened.In all cases the best solution was offered to the customer to restore the propeller’s efficiency as close to the original condition as possible.One of the propeller blades of a 180-meter bulker was severely bent. A fast, on-site solution to restore the propeller’s balance and efficiency was needed.

Detyens Wins $24 Mln Ship Repair Contract

Charleston, S.C. repair yard Detyens Shipyards has been awarded a $24,235,291 firm-fixed-price contract for a 120-calendar day shipyard availability for the regular overhaul dry-docking of the U.S. Navy oiler USNS Patuxent (T-AO 201). Work is expected to be complete by October 2020.The contract includes options which, if exercised, would bring the total contract value to $27,416,444. The Military Sealift Command is the contracting activity.Work will include main and emergency switchboard cleaning…

KONGSBERG propeller Blade Air Emissions Tech for silent seas

Kongsberg Maritime has successfully adapted a propeller concept used in naval applications and is now offering the same operational and environmental benefits to commercial shipping customers.While the naval sector has been using KONGSBERG Blade Air Emission technology for a number of years, with several navies deploying it to limit vessel signature, the process is now being applied to commercial ship propellers to reduce the effect of underwater radiated noise on marine life.By machining a channel into the leading edge of the propeller blades…

Hydrex Earns Belgium, Netherlands Approvals

In close communication with the Dutch Ministry of Infrastructure and Water Management, Hydrex has developed a new method to clean propeller blades underwater. This method complies with the strict environmental regulations in Belgium and the Netherlands. As a result, the company has been given permission to clean propeller blades in both countries.The traditional approach in the propeller maintenance industry is to polish the blades with a grinding disk which can be quite damaging to the propeller.

Ship Owners Are Modifying Propellers to Meet EU MRV Requirement

Belgian underwater repair specialist Hydrex says it is carrying out more modifications to a ship’s underwater areas and equipment in addition to the company’s more common damage rectification work. The increase in this type of work - to propellers, in particular – follows the recent introduction of the European MRV regulation which has seen more shipowners look at ways of further reducing fuel consumption (and emissions) when operating to and from European ports. The EU MRV (Monitoring, Reporting, Verification) regulation entered into force in July 2015.

NYK, JMU Develop Highly Efficient Propeller

Nippon Yusen Kabushiki Kaisha (NYK), MTI Co. Ltd., and Japan Marine United Corporation (JMU) have successfully developed a highly efficient propeller by analyzing the conditions surrounding vessel propellers in actual operation. This new propeller will be installed on two newly built containerships that will be delivered in 2019, and will achieve a 1.2 percent reduction in carbon dioxide (CO2) emissions by improving fuel efficiency. The propeller plays a major role in the propulsion of a ship, and computer simulations and test tanks are used to create an ideal shape, but the actual water flow around the propeller of an oceangoing vessel can be rather complex.

Voices: Rich Merhige, President/Owner, AME

AME is a Florida based engineering services company specializing in marine (Advanced Mechanical Enterprises) and industrial (Advanced Maintenance Engineering) predictive, preventative and corrective maintenance for rotating and reciprocating machinery. Founded by Rich Merhige in 1992, AME has pioneered the use of technologies and equipment to perform diagnostics, maintenance and repair, particularly for private and commercial vessels. As AME celebrates its 25th anniversary, discuss the decision to start the company.

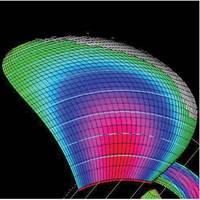

Moving Ahead Powerfully

The layout of ship propellers is a balancing act between optimal power conversion and the avoidance of unwanted cavitation effects, which can result in damage to the propeller structure and higher noise levels. MAN Diesel & Turbo in Frederikshavn, Denmark, is using the computational fluid dynamics (CFD) simulation solution STAR-CCM+ from Siemens PLM Software to model cavitation and optimize ship propellers. Two mid-size container ships of 8,500 TEU – CSCL Europe and CSCL America – will be upgraded by retrofitting a efficient Kappel propeller.

Quick Propeller Repair Prevents Drydocking

Recently a team of Hydrex diver/technicians performed a propeller blade cropping on a 190-meter container bulker berthed in Hamburg. Two parts of the tip of one of the four propeller blades were damaged and needed to be cropped to restore the propeller’s efficiency. Having developed different procedures for different kinds of damage, Hydrex teams are equipped and trained to make the best out of a bent or broken propeller. Ideally, the in-house developed cold straightening technique is used.

World War II Torpedo Found at Scapa Flow

U.K. Royal Navy bomb disposal experts have found a German torpedo from World War II at Scapa Flow in the Orkneys. The torpedo was found on the seabed March 1 after a recent routine sonar survey on behalf of Orkney Islands Council. It was also filmed using an underwater remote-operated vehicle (ROV). Footage showed a seven-meter-long suspected torpedo and Northern Diving Group (NDG) were soon alerted to the incident. “There is currently no threat to shipping or the public and so we have marked the location so that we can return in the near future and safely dispose of it,” Hampshire said.

Wartsila India Signs Pact with CSL

Wartsila India, the Indian arm of Finland-based Wartsila Corporation, has signed a Memorandum of Understanding (MoU) with Cochin Shipyard Ltd (CSL) for setting up a containerised self-sufficient workshop. As per the MOU, Wartsila plans to locate a containerised self-sufficient workshop within the premises of CSL to cater primarily to propeller blade metallurgical repairs and engine component repairs. Wartsila also plans to support CSL with comprehensive engine services, propulsion services and electrical and automation services based on the requirements, said a press release. The MoU was signed by Sunny Thomas, director (technical and operations)…

Conflicting Objectives in Ship Design

“ABS is first and foremost a safety company,” says Richard Korpus, “but safety can arise on many different fronts. Dr. Korpus is Chief Scientist, Computational Fluid Dynamics (CFD) for the American Bureau of Shipping. In this role Korpus supports the Chief Technology Officer (CTO) and underlying organizations through a focus on developing and applying CFD technology. He believes CFD has the potential to change how some of the most challenging problems in marine and offshore classification are solved in the future.

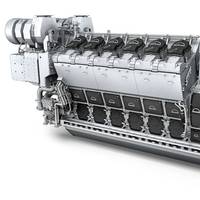

MAN 32/44CR Engine for Trawler Newbuild

Voyager Fishing Company, Ltd., based in Kilkeel, Northern Ireland, has ordered a new trawler/purse seiner, designed by Salt Ship Design in Norway and to be built at Karstensens Skipsværft in Skagen, Denmark. The newbuilding will be powered by a propulsion package comprising a MAN 12V32/44CR main engine, a 4,400-mm ø MAN Alpha VBS 1100 propeller, a two-speed RENK Type RSVL1000 gearbox, and an Alphatronic AT3000 remote control system. Vessel delivery is scheduled for August 2017.

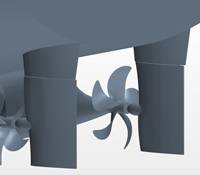

Van Oord Orders Two New Dredgers

Rotterdam-based dredging and marine contractor Van Oord has recently ordered two trailing-suction hopper dredgers as part of its continuous investment program. The vessels will be constructed at CNN LaNaval Shipyard in Sestao, Spain with delivery dates scheduled for 2017. Each vessel will feature a complete MAN Diesel & Turbo propulsion package with MAN 6L48/60CR engines, RENK gearboxes with PTO, MAN Alpha CP Propeller systems, AHT (Alpha High Thrust) Propeller nozzles and MAN Alpha AT3000 propulsion-control systems.

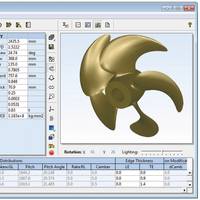

Propellers: One Size and Shape Does Not Fit All

Hydrocomp’s newest release of PropCad incorporates 3 years of enhancements. Propellers are surprisingly complex devices, especially considering most are a solid piece of metal with no moving parts. The variation in vessels and operational requirements leads to wildly different designs, from noise-sensitive propellers for luxury cruiseliners to wide-blade sets for tugs. With different combinations of diameters, pitches, blade styles, and blade counts, there is no limit to the design alternatives available.

Refurbished Seajacks Vessels Leave Shipdock Amsterdam

Seajacks Leviathan and Seajacks Kraken are prepared for their coming assignments, following a series of repair and renewal jobs by Shipdock Amsterdam. The shipyard, part of Damen Shiprepair & Conversion, had been commissioned for the two jack-ups by Seajacks UK Ltd. The Great Yarmouth (United Kingdom) based company has assigned the shipyard various and different major and minor adjustments on the two jack-up sister vessels in between North Sea offshore windfarm and oil & gas installation contracts.

Five Minutes with N-KOM CEO Abu Bakar Mohd Nor

In the Middle East there has been a level of shipbuilding infrastructure investment unmatched, with companies such as N-KOM in Qatar among the leaders. N-KOM CEO Abu Bakar Mohd Nor shares his insights on growth & opportunity in the Middle East. When you look at the expanse of your operations, what do you count as the primary strength of your company? One of the most important strengths N-KOM has apart from its strong parentage is being strategically located in Qatar, the world’s leading exporter of liquefied natural gas (LNG) and at the heart of the Arabian Gulf…

Offshore Momentum Escalates at Gibdock

Strategically located Gibraltar shipyard Gibdock has continued its run of technically advanced offshore support vessel repair and maintenance projects, securing a contract involving a returning customer. The Viking Vanquish, a high capacity 3D seismic survey vessel operated for CGG, has undergone a 21-day program of works, leaving the shipyard’s drydocks in mid-September prior to sea trials. Based in France, CGG operates 23 seismic survey vessels, after acquiring Fugro’s geoscience division earlier this year - claimed to be the largest high-end seismic fleet in the industry.

First Havyard WE Design Delivered to Fafnir Offshore

Havyard Ship Technology's build 120 'Polarsyssel', a Havyard 832 L WE design, was delivered to Fafnir Offshore yesterday. It will go straight on assignment for the Governor of Svalbard In March 2013, Havyard signed a contract with Icelandic shipping company Fafnir Offshore for the building of a Havyard 832 L WE platform supply vessel (PSV). A month later, Fafnir had secured a long-term contract for the vessel, which will operate six months a year for the Governor of Svalbard for a period of six years. 'Polarsyssel' is a Havyard 832 L WE design that, in principle, is equipped as a normal PSV. Havyard Design & Solutions' WE design has been specially developed with a view to ensuring comfortable, safe and economical operation in demanding weather conditions and in Arctic waters.

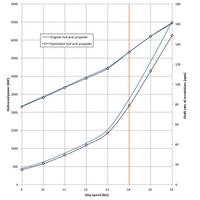

New Propeller Optimization Process Can Analyze 10,000 Designs a Day

A newly developed propeller optimizer makes it much faster to identify propeller-hull reactions and reach design decisions. In the EU project STREAMLINE the fuel efficiency of a chemical tanker was improved by optimizing the hull form and propeller. To this end, MARIN used its hull optimization program PARNASSOS EXPLORER and a newly developed propeller optimizer. The hull form itself was optimized for low resistance and for having a wake field as rotationally symmetric as possible, while simultaneously maintaining the displacement and sufficient space for the engine room.