Seaspan Selects Alfa Laval's Steam Solution

Seaspan Ship Management selected Alfa Laval to help resolve steam balance and redundancy issues connected to sulfur-compliant fuels. The solution – an integrated steam boiler plant comprising oil-fired steam production, waste heat recovery, advanced control and connectivity – will be implemented on eight Seaspan-owned large container ships.Prior to the IMO global sulfur cap’s entry into force, Seaspan Ship Management made the decision to work with sulfur-compliant fuels on its container vessels.

INSIGHTS: Dennis Wilmsmeyer, Executive Director, America's Central Port

Dennis Wilmsmeyer was appointed Executive Director at America’s Central Port on July 1, 2010, prior to which he served 11 years with the Port District, six as General Manager.With over 30 years of experience, Dennis brings a wealth of knowledge and expertise to the table in the areas of transportation, planning, and economic development. His responsibilities include developing the Port’s 1,200-acre industrial park and business campus, redeveloping a former military logistics center…

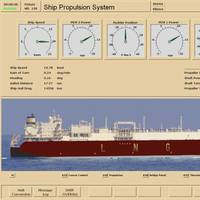

Kongsberg to Deliver Simulator Package to GasLog

Kongsberg Digital (KDI) will deliver to GasLog a comprehensive liquefied natural gas (LNG) simulator package designed to enable new levels of safety and operational training for the owner/operator’s professional crews.GasLog operates 27 LNG vessels through its subsidiary, GasLog LNG Services and has seven ships currently on order. The KDI contract represents a commitment and investment on GasLog’s part to provide a high-level training environment for their crews, solely focused on LNG operation.The scope of supply is based on an integrated…

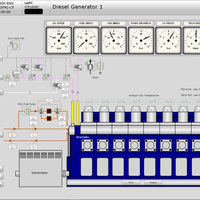

DNV GL Approves Kongsberg Engine Room Simulators

Kongsberg Digital has received DNV-GL statements of compliance for two of its newest Engine Room Simulator models designed to provide in-depth training on the K-Sim Engine simulator platform. The DNV GL-ST-033 March 2017 Maritime Simulator Systems certification, which is based on the requirements of STCW Convention, Regulation I/12, was awarded to the DEDF Cruise Ferry and L11 MAN 6S70 ME SCC K-Sim Engine models in December 2017. Now commercially available to all K-Sim Engine users…

MN100: Massachusetts Maritime Academy

Massachusetts Maritime Academy offers seven undergraduate Bachelor of Science degrees and two graduate Masters of Science programs. The regiment of cadets is comprised of students from around the globe. The academy operates a training vessel used to acquire sea service for the cadets. Two tugs (Alert and Hercules) and a barge support the Mate of Towing program. The Academy has a vast array of simulators used for undergraduate and professional mariner training. The engineering…

Scrubbers Installed on Another Great Lakes Bulker

The Interlake Steamship Company’s M/V Lee A. Tregurtha sailed today from Fincantieri Bay Shipbuilding Company in Sturgeon Bay, Wisc., becoming the shipper’s third self-unloading bulk carrier to be outfitted with exhaust gas scrubbers. Interlake became the first U.S.-flag fleet to test scrubbers on the Great Lakes in April 2015 after pioneering the emission-reduction technology on its M/V Hon. James L. Oberstar. Earlier this month, the M/V James R. Barker sailed as the fleet’s first 1,000-footer with scrubbers. “With the Lee A.

Interlake Steamship Continues Scrubber Upgrades

The M/V James R. Barker sailed Sunday from Fincantieri Bay Shipbuilding Company in Sturgeon Bay, Wisc., becoming Interlake Steamship Company’s first 1,000-footer and its second self-unloading bulk carrier to be outfitted with exhaust gas scrubbers. Interlake became the first U.S.-flag fleet to test scrubbers on the Great Lakes in April 2015 after pioneering the emission-reduction technology on its M/V Hon. James L. Oberstar. “Implementing this innovative scrubber system on our 1…

Interlake Steamship Begins 2016 Sailing Season

The Interlake Steamship Company’s Dorothy Ann-Pathfinder, an articulated tug-barge unit (ATB), departs winter layup today to begin early-season shuttles of iron ore for ArcelorMittal, an integrated steel and mining company with blast furnaces at the head of the Cuyahoga River. A workhorse of Interlake’s nine-vessel fleet, the combined 711-foot Dorothy Ann-Pathfinder is one of Interlake’s two River-Class vessels, a designation given to ships that can traverse the narrowest harbors of the Great Lakes.

MN 100: Massachusetts Maritime Academy

Massachusetts Maritime Academy is one of nine Massachusetts State Universities. Established in 1891, the academy now offers seven undergraduate and two master’s degrees. Approximately 50-60% of the undergraduates are enrolled in unlimited USCG Merchant Marine License preparatory programs. 1,350 students are members of the Regiment of Cadets residing on campus. The academy operates a training vessel (T.S. Kennedy) used to acquire sea service for the cadets. The academy also has an 87 ton auxiliary training vessel (Ranger) used during the academic semesters for coastal navigation.

Newport News, Hampton Convert Trash Into Steam Energy

Newport News Shipbuilding (NNS), a division of Huntington Ingalls Industries, is partnering with the City of Hampton to convert shipyard trash into steam power. As part of the new Single Stream Recycling Program, the shipyard's solid waste is incinerated at Hampton's award-winning steam plant facility and converted to steam through a process known as "waste-to-energy." The energy is then used to power NASA Langley Research Center (NASA LaRC) facilities. "Just last year NNS sent more than 10…

USS Makin Island: Proven Fuel Efficient

USS Makin Island (LHD 8) is the last in a series of 8 amphibious assault ships of the WASP-class built by Northrop Grumman Shipbuilding at its Pascagoula, Miss. shipyard. Though last, it is the first in the series fitted with hybrid electric gas turbine propulsion, and recently returned to its San Diego homeport after its first deployment. “During the seven-month deployment, the ship’s hybrid-electric propulsion system saved more than four million gallons of fuel resulting in an estimated cost savings in excess of $15 million,” the Navy claims.

Navy's Great Lakes Energy Project Moves Ahead

Naval Station (NAVSTA) Great Lakes and Naval Facilities Engineering Command (NAVFAC) Midwest are taking the next step toward decentralizing the base's steam heat delivery system, one of the largest energy efficiency initiatives in the 100-year history of the base. Teams of prospective project contractors and NAVFAC representatives will conduct site visits in mid-January at many of the buildings on base to be affected. As part of the bidding process, this will give the companies a better sense of what will be involved in the project, to be awarded by summer 2012. "This is one of the most significant projects undertaken within the region," said NAVFAC Midwest Commanding Officer Capt. Scott Bernotas. "Not only is the project large in scope, but also in future benefit.

Kongsberg Simulators with Multiple DNV Approvals

Engine room simulators approved to the highest DNV certificate level. A total of 14 Kongsberg Maritime Engine Room Simulator models received new Det Norske Veritas (DNV) Statements of Compliance in December 2011. The approvals are according to the revised standards laid out in DNV – Standard for Certification of Maritime Simulators No. 2.14 January 2011, which is based on the requirements of STCW Convention, Regulation I/12 and include the new 2010 amended convention that came into force from January 1st 2012.

Kongsberg Releases Dual Fuel Diesel Electric Simulator

Ongoing simulation model development focuses on vessel efficiency. Kongsberg Maritime has released a sophisticated Engine Room Simulator (ERS) model based on a Dual Fuel Diesel Electric (DFDE) Engine Room configuration from a modern liquefied natural gas (LNG) carrier. The new DFDE model will offer the most sophisticated simulator training for LNG engineers available today. DFDE driven vessels are becoming more and more common and the new engine room simulator model from Kongsberg…

Thomas Miller Helps Renovate of Africa’s Oldest Ship

Believed to be the oldest ship still afloat in Africa, the 124.6 ft long motor ship Chauncy Maples is to be renovated as a floating clinic to bring primary health care to half a million of the world’s poorest people living around Lake Malawi. The necessary funds are now being raised by the Oxford-based Chauncy Maples Malawi Trust with considerable support from Thomas Miller, a London-based specialist insurance company, which has chosen to make the renovation of Chauncy Maples the focal point of its 125th anniversary celebrations.

Transas Releases New Version of Engine Room Simulator

Transas has commercially launched the latest version of its Engine Room Simulator, ERS 4000. The new simulator is enhanced with a number of new significant capabilities aimed at satisfying the increasing demands of users of this kind of simulation product. The modified ERS 4000 simulator features a modern design for the dedicated hardware set with new control panels, and some essential improvements have been made to the simulator’s functionality. One of these is the new configuration for the Electric Power Plant, which now includes Steam Turbo-generator and the updated Steam Plant.

Technology: Transas Releases New Version of Engine Room Simulator

Transas commercially launched the latest version of its Engine Room Simulator, ERS 4000. The new simulator is enhanced with a number of new significant capabilities aimed at satisfying the increasing demands of users of this kind of simulation product. The modified ERS 4000 simulator features a modern design for the dedicated hardware set with new control panels, and some essential improvements have been made to the simulator's functionality. One of these is the new configuration for the Electric Power Plant, which now includes Steam Turbo-generator and the updated Steam Plant. The accurate mathematical ship models incorporated in the simulator have been improved and extended by the new vessel types, Tanker LCC and Trawler.

Wärtsilä Dual-Fuel Engines for 153,000 m3 LNG Carrier

Wärtsilä Corporation has been awarded a contract by the French shipbuilder Chantiers de l'Atlantique to supply dual-fuel main engines for a new 153,000m3 LNG carrier. The LNG carrier has been ordered by the French gas distributor Gaz de France for delivery in October 2005. It will be employed in the shipment of liquefied natural gas (LNG) from Norway or Egypt, but is also designed for the alternative of trading on the spot market. The vessel will have gas-electric propulsion, with four dual-fuel engines driving generators to supply electricity for the single propeller plant. The engines will burn boil-off cargo gas with a small quantity of liquid fuel for ignition. They will mainly can run on gas with liquid fuel as back-up, and can be switched over automatically as the need arises.

Gas Ships: Large LNG Carriers ABS Addresses Tech Concerns

As the LNG trade significantly increase over the next decade, transporting the fuel in ever larger, more sophisticated ships means particular attention must be paid to technical issues to ensure the present and long-term viability of the new generation of larger LNG carriers. Operators continue driving the demand for larger LNG ships to take advantage of the economies of scale. "By increasing the size of the standard LNG carrier from about 145,000 to 200,000 cu. m. and even larger, it is estimated that there could be a reduction in transportation costs by as much as 15 percent," said James Gaughan, ABS Senior Consultant, Energy Project Development Group. Another advantage with larger LNG ship designs is a reduction in the amount of cargo boiled off as a percentage of volume.

What is in John Garner's Pocket

You don't really know a boat until she's hauled. Plying her trade on the water, her best half's submerged out of sight. We think we recognize her - "oh, there's Odin," or "Shelby Rose," or "Twintube" - but what are we seeing? The lines of the deckhouse, the shape and placement of the wheelhouse, the arrangement of the stacks? These are the parts known as the superstructure - "super," in this case, meaning simply "upon." It's a little like saying we recognize someone by his hat. The boat's defining structure starts at the main deck and goes downward from there. What little we see of it is low on the horizon. There's the deck's line, along with a smattering of bulwarks.

Wartsila Awarded Contract

shipyard Chantiers de l'Atlantique. Due for delivery in 2004, this newbuilding is breaking away from traditional practices in the propulsion of LNG (liquefied natural gas) carriers. It will be the first LNG carrier to be powered by electric propulsion, and one of few to have internal-combustion engines instead of the more usual steam turbine plant. The four dual-fuel engined generating sets will meet all the ship's propulsion and shipboard electrical requirements. engines each develop 5700 kW at 514 rev/min. This membrane-type vessel (GTT-CS1) will be employed transporting LNG from Skikda in Algeria to Fos near Marseilles. take about one week at a service speed of 16 knots, which can be achieved with three of the four generating sets.

Historic Dredge Gets New Lease on Life

By Ed Voigt, U.S. The U.S. Army Corps of Engineers oldest dredge is now also one of its youngest. The dustpan dredge Potter, the Corps last and longest-serving steam-powered dredge, helped keep the Mississippi River open to navigation for almost 70 years. Now she is back home at the St. Louis District Service Base after a $20 million repowering project by the district and the Corps' Marine Design Center (MDC). Halter Marine, Inc., of Gulfport, Miss, was the contractor. She departed Halter's New Orleans shipyard Sept. 29 with the same overall profile (minus smokestacks) and capabilities, but with an all-new stern and a diesel-electric power plant. Named for Brig. Gen.

LNG Breakthrough For Wärtsilä

Wärtsilä Corporation received an order to supply four Wärtsilä 6L50DF dual-fuel engines to power a 75,000 cu. m. LNG carrier contracted by the French gas holding company Gaz de France at the French shipyard Chantiers de l'Atlantique. Due for delivery in 2004, this newbuilding is breaking away from traditional practices in the propulsion of LNG (liquefied natural gas) carriers. It will be the first LNG carrier to be powered by electric propulsion, and one of few to have internal-combustion engines instead of the more usual steam turbine plant. The four dual-fuel engined generating sets will meet all the ship's propulsion and shipboard electrical requirements. The Wärtsilä 6L50DF engines each develop 5,700 kW at 514 rpm.