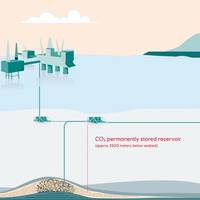

Northern Lights CCS: Trailblazing the Path to Europe’s Net Zero Emissions

In the global quest for achieving net zero emissions and slowing down global warming, carbon capture and storage (CCUS) technology has emerged as an important solution. Among the notable projects being developed in the field is the Northern Lights offshore carbon capture and storage project in Norway, a country with long experience with offshore CO2 storage.The transition to a sustainable energy future requires innovative solutions that go beyond simply halting fossil fuel projects.

INSIGHTS: Sean Fernstrum, President, R.W. Fernstrum

This month, listen in as Sean Fernstrum weighs in on how his firm arrived at its enviable market position, what comes next, and why.Sean Fernstrum is a third-generation owner of R.W Fernstrum & Company. He graduated from Michigan Technological University in 1990 with a Bachelor of Science degree in Scientific and Technical Communications. After college, he came home to Menominee, Michigan and began working as a Technical Writer at R.W. Fernstrum & Company. He has been President of the company for the last 8 years.

Interview: 50 Years in the Polymer Repair Market

With 50 years dedicated to polymer coating and composite manufacturer Belzona, Geoff Binks looks back on his experience in the industry and maintenance sector. Geoff Binks was born and raised in Harrogate and joined Belzona in 1965 direct from Technical College with a chemistry background. He first worked in R&D on a broad range of products, particularly the Belzona Metals which saw radical development in 1968 with the introduction of the first Belzona Super Metal formulation.

LR Approval for GTT's Mark V Technology

GTT, the world leader in the design of membrane containment systems for the maritime transportation and storage of LNG (Liquefied Natural Gas), announces that its new containment system Mark V has earned a General Approval from the classification society Lloyd's Register. This is the second validation for GTT's latest technology, after Mark V was recently granted a similar General Approval from DNV-GL. The Mark V technology was developed after a number of years of research and development. It is an optimized version of the Mark III system and its sister Mark III Flex. As with the Mark III and Mark III Flex, the Mark V technology is composed of a double insulation with reinforced polyurethane foam.

GTT’ Mark V Earns DNV GL General Approval

GTT, a designer of membrane containment systems for the maritime transportation and storage of liquefied natural gas (LNG), announced that its new containment system Mark V has been granted General Approval for Ship Application (GASA) by classification society DNV-GL. GTT called the validation by DNV-GL of the Mark V technology a major step toward its commercialization following two cooperation agreements GTT signed during the first half of 2015 with the shipbuilders Hyundai Heavy Industries and Samsung Heavy Industries to confirm the industrialization of the system. After some years of research and development, the Mark V technology is an optimized version of the Mark III system and its sister Mark III Flex.

HHI to Industrialize GTT’s Mark V Technology

GTT (Gaztransport & Technigaz) has signed a cooperation agreement with the South Korean Shipbuilder Hyundai Heavy Industries (HHI) for the industrialization of GTT’s new Mark V technology. A similar partnership was signed a few weeks ago between GTT and Samsung Heavy Industries. The agreement includes the development and qualification of an innovative welding robot for the primary stainless steel and secondary invar membranes. The robot will permit the optimization of the welding process and a reduction in construction time. After some years of research and development, the Mark V technology is an optimized version of the Mark III system and its sister Mark III Flex.

WTC Steel Becomes Part of Bow for USS New York

On September 9, 2003, remnant steel from the World Trade Center twin towers will be cast into the future USS New York amphibious transport dock ship, LPD 21. The ship is named for the state of New York and recognizes the courage and commitment of New Yorkers during the 9/11 tragedy. Amite Foundry and Machine in Amite, LA, a subcontractor to the shipbuilder Northrop Grumman Ship Systems, will perform the casting. Thousands of pounds of steel transported from the debris field in Staten Island, NY, will be melted down and poured into the bow stem cast of New York. As part of the bow, the stem and WTC steel will always be the first part of the ship to sail into future 21st Century expeditionary warfare missions.

Great Ship: Great Ships of 2003

Ship Owner Mediterranean Shipping Co. S.A. MSC Linzie is the first vessel of a new vessel type developed and designed by Hanjin which adopts the new Panamax length design of 294.05 m. Apparently the design series and Hanjin's well-established reputation in this niche has proved attractive, as the company has, to date, logged orders for 24 ships of the new design. As mentioned above, its length is the maximum for Panama canal, i.e. 294 m. So it has been designed to move flexibly both in Pacific Ocean and in Atlantic Ocean through Panama canal, which is one of the main feature that makes it popular among the operator. This ship offers the maximum intake of 5,060TEU.

New Diesel Engine Lines Available for Workboat Market

In recent months several diesel engine manufacturers have expanded their existing engine and generator ranges to include models suitable for workboat, large yacht and fishing vessel applications. This translates to more propulsion choices for boat builders and owners. Following is a look at four newly launched lines. Last September, MTU introduced the new 8000 series, moving the company into medium-speed engine market. The first engine of the line is the 20V 8000, which is capable of producing 9,000 kW at 1,150 rpm. The 20V is primarily intended to be used as main propulsion for large yachts and workboats, as well as for diesel-electric propulsion and onboard power supply systems in cruise ships.