Tech File: Study Suggests Pre-insulated Plastic Piping Aids Passenger Ships Efficiency

A new study by GF Piping Systems and Foreship shows HVAC applications on passenger ships offer significant potential for improvement. The study, comparing a baseline steel piping system with pre-insulated polyethylene pipes in an air conditioning chilled water system revealed that plastic is more efficient in four areas: It decreases fuel consumption, reduces greenhouse gas emissions, lowers costs, and slightly improves EEXI and CII values.GF Piping Systems, the Swiss flow solutions provider…

Marine Coatings: Polyflake Protects against Corrosion

Corrosion starts from the inside out. The alkali that neutralizes acid water - and the acid water produced in a gas scrubbing system - are corrosive. Containment surfaces resistant to both alkali, acid water and their combination provide a safer ship with less expensive maintenance. While selecting metal alloys as more resistant to either acid or to alkali, facing all conditions simultaneously is problematic, as temperature plays an important role in pitting corrosion.Ultimately…

Grooving the Way: Back to the Future

Anything but new, the Victaulic method of pipe-joining has been around for a long time. Armed with myriad type approvals from most IACS groups, Victaulic’s output will no doubt (and soon) form a part of your marine equipment for a long time to come. The conservative and staid domestic waterfront, especially where it intersects boatbuilding and repair, recently set sail for increased efficiencies, driven in part by emerging technologies, but also through improved management and new assembly techniques. It was in 2013 that Boysie Bollinger’s son, Chris Bollinger, then a member of the Bollinger senior management team, proclaimed, “Boatbuilding is evolving into something that will more closely resemble manufacturing…

Grooving the Way: Back to the Future

Anything but new, the Victaulic method of pipe-joining has been around for a long time. Armed with myriad type approvals from most IACS groups, Victaulic’s output will no doubt (and soon) form a part of your marine equipment for a long time to come. The conservative and staid domestic waterfront, especially where it intersects boatbuilding and repair, recently set sail for increased efficiencies, driven in part by emerging technologies, but also through improved management and new assembly techniques. It was in 2013 that Boysie Bollinger’s son, Chris Bollinger, then a member of the Bollinger senior management team, proclaimed, “Boatbuilding is evolving into something that will more closely resemble manufacturing…

Viega Introduces New Reducer and Union Fittings

Twelve new P x P reducer and P x FPT union options are available for the Viega MegaPress and MegaPressG systems for carbon steel piping systems. Viega said it has introduced 12 new reducer and union options for the Viega MegaPress and MegaPressG systems for schedule 5 to schedule 40 carbon steel piping systems in sizes 1/2" to 2". The Viega MegaPress system uses modern cold press connections for pipe installation. The Viega MegaPress system is ideal for hydronic heat, chilled water, compressed air, fire sprinkler systems, low-pressure steam and vacuum lines.

Harris Pye Announces New Scrubber Installations

The Harris Pye Engineering Group is currently engaged in turnkey scrubber installation packages for major cruise line companies. On August 3, 2016 Harris Pye completed the installation of an Advanced Emission Purification System, fully automated, which was duly DNV GL certified which met with MARPOL regulation 14 of Annex V1 for the control of emissions complying to regulations 14.1 or 14.4. The design package for open and closed loop systems was utilized to model and fabricate all piping systems, hardware integration, and major/minor steelworks. Along with new exhaust tail pipes, sea chests were installed with the vessel in service along with the associated overboard discharges.

Power and Endurance Ready for Austrailian Waters

Wamalhanha is the final newbuild in a series of six tugs of the Robert Allan Design, RAstar 3200 where her main duties will be terminal activities, escort duties, ship assist, towage duties. She was named on September 24, 2014 at UZMAR Workboat and Tug Factory for delivery. Rio Tinto owns six vessels in this series, these arePilbara Apollo, Kashima, Matsuzaka, Barrura, Gurrgura and Wamalhanha.These vessels have been adapted to requirements for the work in Australian Iron Ore Terminals including power and improved NOx and SOx reduction for the exhaust emissions.

All-electric Tube Benders Take a Step Forward

The tube bending machine innovator Unison said it is moving the technology forward again, with the completion of a groundbreaking all-electric machine that is capable of bending tubes and pipes up to 9 inches/225 mm in diameter. The availability of all-electric machines at this new size level brings the benefits of instant set-up and right-first-time precision bending to many new applications in sectors including shipbuilding, powergen and oil, gas and chemical processing. According to Unison…

WW II Liberty Ship Leak-free after 70 Years

To address the sudden need for supplies overseas during World War II, the United States government launched the Emergency Shipbuilding Program in 1941 that resulted in the construction of more than 5,700 cargo ships for the U.S. Maritime Commission. 2,710 of these vessels were of a design that became known as Liberty ships. These vessels were designed as economically and quickly built cargo steamers that formed the backbone of a massive sealift of troops, arms, materiel and ordnance to every theater of the war. Two-thirds of all cargo that left the U.S.

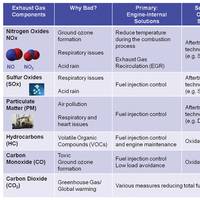

EPA Tier 4 Emission Regulations

Implications on U.S. The next round of emission regulations will bring significant impacts to the design, construction, and operation of U.S. commercial and government vessels starting in 2014. The impending EPA Tier 4 regulations directly apply to high and medium-speed diesel engines used in workboats, ferries, small cargo ships, and government vessels. These regulations represent the most significant reduction of marine emission levels to date, specifically in the form of nitrogen oxides (NOx). Natural gas fueled engines present one path to compliance, but not the only path.

Remote Monitoring: The Bottom Line for Fleet Optimization

By any yardstick, remote monitoring is fleet optimization in the new millennium. You’re all over it: optimizing your fleet. But, what does that mean? For some operators, it means making sure their mix of vessels meets the needs of their customers and the prevailing winds of the economy. For others, it entails reading the tea leaves just right when it comes to deciding on time charters or dipping one’s toes into the spot markets. Still others focus on the closely linked Holy Grail of reduced bunker consumption and minimal stack emissions. For all of these cool customers, however, “remote monitoring” will also be part of that equation. That said; defining what remote monitoring means is another thing altogether. Remote monitoring of on board metrics or data points is here.

FloScan: ABS Certification for New Flowmeters

FloScan Instrument Company said that the new Series K Stainless Steel Diesel Flow Sensor that has earned ABS Product Design Assessment Certification. FloScan is a manufacturer of fuel monitoring systems for permanent installation on diesel and gasoline engines. FloScan Systems are installed worldwide on commercial and recreational vessels, stationary industrial generators and general aviation aircraft. With the introduction of the new Stainless Steel Series K Flow Sensor, FloScan…

New FloScan Flowmeters Earn ABS Certification

FloScan Instrument Company, Inc. announced that its new Series K Stainless Steel Diesel Flow Sensor has earned ABS Product Design Assessment Certification. Companies operating ABS-Classed vessels will now be able to use FloScan fuel computers, networking components and software applications to reduce operating costs and improve fuel accountability. FloScan is a manufacturer of fuel monitoring systems for permanent installation on diesel and gasoline engines. FloScan Systems are installed worldwide on commercial and recreational vessels…

FloScan Receives ABS Certification

FloScan Instrument Company, Inc. has announced ABS Product Design Assessment Certification for its new line of Series K Stainless Steel Diesel Fuel Flowmeters. This certification permits the installation of FloScan Fuel Monitoring Systems on ABS-classed vessels requiring steel piping components. FloScan is a global manufacturer of Fuel Monitoring Systems for permanent installation on diesel and gasoline engines. FloScan Systems are installed worldwide on commercial and recreational vessels, stationary industrial generators and general aviation aircraft ...

Sequestration Prevents Repair of USS Miami

By Rear Adm. USS Miami was set ablaze by an arsonist in May 2012. The Navy recently completed a comprehensive assessment of the extensive fire damage, finding that the submarine is fully repairable from a technical perspective; however, inspections have revealed a greater scope of work than originally envisioned. Under the financial constraints of sequestration, the Navy said it cannot afford to undertake the repairs. Sequestration effects this past year (work force limitations)…

Shipbuilding: DDW's Future is Bright

During the past two years Drydocks World (DDW) has suffered from the restraints of a financial problem following the purchase of one shipyard in Singapore and one on the Indonesian island of Batam (both former Pan United shipyards) and two more on Batam (both former Leroy shipyards). This debt has now been restructured and the management of those yards has been taken over by China’s Paxocean, thus leaving DDW is a much better state and looking forward to a better future. The main yard of DDW is Drydocks World – Dubai (DDW-D)…

Drydocks World Finalizing Conversion

Naming ceremony held in the presence of senior personnel. Drydocks World, a maritime services provider, after the naming ceremony held yesterday by OLT LNG Offshore Toscana, announced that the FSRU Toscana conversion project at the Dubai based shipyard, is going to be finalized. The Floating Storage and Re-gasification Unit is intended for a 20 year design life 12 nautical miles off the shores of north-west Italy, in the waters of the Tyrrhenian Sea close to Livorno. The Liquefied Natural Gas (LNG) carrier Golar Frost…

Barge Built by FirstWave/Newpark

E.I. duPont de Nemours & Co., Inc. has received EIDC 13, the second of three identical barges being built for the company by FirstWave/Newpark Shipbuilding. The inland service, double-skin tank barge measures 230 x 42 x 12 ft., and has a capacity of 2,200 short tons of product. The barge is certified by the USCG and will be used to transport sulfuric acid, oleum or spent sulfuric acid. It has two cargo tanks wth an electric-driven Lewis four-in. acid pump, stainless steel piping and provisions for inclusion of a vapor control system at a later date. The vessel was designed by Shearer & Assoc., Inc. FirstWave/Newpark Shipbuilding is also constructing a 250 x 42 x 14 ft. inland service double-skin tank barge for E.I. duPont capable of carrying either virgin or spent sulfuric acid.

ACL Launches First in Tanker Barge Series

American Commercial Lines Inc. announced that it launched the first in a series of tanker barges to be constructed at its Jeffboat manufacturing facility through 2012 to replace retiring fleet capacity. The new barges will improve the age profile and quality of ACL's fleet. The first of these barges, launched on Tuesday, May 10 by ACL's President and CEO Mike Ryan, was a clean service tanker with a capacity of 30,000 barrels. It includes a redesigned stainless steel piping system and a new radial rake design that will also be found on the tankers the Company plans to build over the next 20 months. "We are excited to have launched the first of the new replacement tankers that we will be building this year and next to significantly improve the quality of our liquids fleet for our customers…