Obscure Traders Ship Half Russia's Oil Exports to India, China After Sanctions

A Liberian-flagged oil tanker set sail in May from Russia's Ust-Luga port carrying crude on behalf of a little-known trading company based in Hong Kong. Before the ship had even reached its destination in India, the cargo changed hands.The new owner of the 100,000 tonnes of Urals crude carried on the Leopard I was a similarly low-profile outfit, Guron Trading, also based in Hong Kong, according to two trading sources.The number of little-known trading firms relied on by Moscow to export large volumes of crude exports to Asia has mushroomed in recent months…

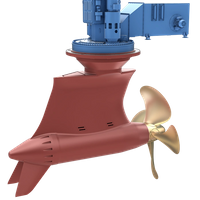

Rolls-Royce Unveils New Podded Propulsion Range

Rolls-Royce has launched a new range of smaller, more compact podded propulsion systems: the ELegance pods – one with an open propeller, the other ducted.Per Nahnfeldt, General Manager Product – Electric Propulsion, Rolls-Royce, said, “For many years we have recognized the gap in the propulsion market for smaller pods, including ice-class, in the 1.5MW to 7MW power range. These new pods – based on our Permanent Magnet technology – complement our broad product portfolio and sit well with our range of frequency drives and electrical systems.

#BTC100 History

Bouchard Transportation Co. acquires its first oil barge, a sunken 15,000 barrel vessel, which Capt. Fred Bouchard purchased for $100. After raising this vessel, he towed it from Jacksonville, FL, to a Norfolk, VA, shipyard, where it was then converted to a hot oil system oil barge and named the John Frederick. #BTC100 The July 2018 edition of Maritime Reporter & Engineering News will feature a special “Bouchard Transportation Co. Celebrates 100 Years” magazine. For more information contact: Greg Trauthwein, [email protected], t. 516-810-7405.

Maersk Fluid Technology Sees SEA-Mate Order Influx

Maersk Fluid Technology (MFT) has reported a recent influx of orders for its SEA-Mate Blending-on-Board (BOB) system as confirmation of industry demand for technological solutions that enable ship operators to blend fit-for-purpose cylinder lubricant compositions on board their vessels that match actual engine operating conditions and fuel sulphur levels. The use of this type of technology can reduce cylinder oil consumption and alleviate issues such as cold corrosion and excessive cylinder wear, according to MFT.

Maersk Fluid Technology Upgrades SEA-Mate

Maersk Fluid Technology (MFT) said it has recently upgraded its SEA-Mate Blending-on-Board Value Calculator to include a mobile optimized version that will assist in calculating savings, based on a variety of real life scenarios. The SEA-Mate Blending-on-Board (BOB) system enables the crew on board the vessel to blend an engine-specific fit-for-purpose cylinder lubricant with the optimal neutralization and detergent properties. The in-use two-stroke engine system oil is blended with a high-BN cylinder oil.

Big Win for Maersk Fluid Technology’s BOB System

In the second half of 2015, Maersk Fluid Technology introduced a new version of its cylinder oil ‘Blending-On-Board’ (BOB) system, targeting medium-sized 2-stroke propulsion engines with a cylinder bore between 420 and 680 mm. Now the first volume order has been placed for retrofit of the SEA-Mate B1000 system onto 12 tankers delivered to Maersk Tankers between 2005 and 2008 – ten vessels equipped with Wärtsilä (WinGD) RTA and RT-Flex engines with a bore between 580 and 620 mm and two vessels with engines designed by MAN Diesel & Turbo. The order has been placed after careful evaluation of the expected payback time, which was found to be less than 2 years when taking the proven fuel savings, system oil and cylinder oil cost reductions into account.

LUKOIL Introduces New Crankcase and Cylinder Oils

LUKOIL Marine Lubricants has introduced the newly formulated NAVIGO 6 CO crankcase oil and NAVIGO 70 MCL AW cylinder oil, offering newly designed additive packages and additional benefits with regard to thermal and oxidation stability, corrosion prevention and wear protection. According to LUKOIL , the new products come as a result of two years of focused research and development activities aimed at enhancing its standard crankcase and cylinder oil portfolio. NAVIGO 70 MCL AW…

Maersk to Address ‘Blending-On-Board’

Visitors to the 2016 European Marine Engineering Conference in Amsterdam this year will be able to hear a keynote speech from Maersk Fluid Technology managing director Jens Byrgesen, who will talk about his company’s success with “Blending-On-Board” lubrication technology. Maersk’ SEA-Mate Blending-On-Board concept is based on proprietary technology designed to enable the operator to custom blend a fit-for-purpose cylinder lubricant from recycled two-stroke system oil and a cylinder oil concentrate with a base-number up above 300 BN.

Marine Lubricants: New Year, New Emission Rules

January 1, 2015 is an important date for ship owner and operators to ensure that their vessels, when operating inside ECA zones, are doing so in compliance with strict new emission edicts concerning the emission of sulfur. – to discuss some of the technical and logistical matters you must consider. The move to low sulfur fuels is well recorded, but from your point of view, describe the situation that ship owners face regarding fuel selection and cylinder lubrication come January 1, 2015?

New STAUFF Mini Water Vac Cleans Oil Continuously

The STAUFFMini Water Vacpurifies hydraulic system oil, eliminating water, gas and particulate matter. The purified oil satisfies the most stringent quality requirements. The STAUFFMini Water Vac dehydrates and cleans most types of oils such as lubricating, hydraulic, transformer and switch oils while it neither removes nor alters oil additives. The water removal process is based on pure vacuum evaporation inside a vacuum chamber at a maximum temperature of +65 °C / +149 °F. Solid particle removal is achieved through a field-proven STAUFF Systems Micro Filter.

Castrol Challenges Scavenge Drain Oil Analysis Methodology

Concerns over corrosive wear risk in cross-head engines led Castrol Marine to question the rigour of some widely used scavenge drain oil analysis (SDA ) techniques. Factors influencing scavenge drain oil characteristics include fuel sulphur level, cylinder oil BN level, system oil contamination and operating profile. Accuracy is critical in SDA interpretation, not least because it supports feed-rate assumptions that are critical to cylinder oil performance, Castrol said. “It is not possible to analyze results accurately without comprehensive knowledge of the fuel oil, the new and used system oil, feed rates and operational data collected from the engine at the time of sampling,” said Paul Harrold, Castrol Marine Technology Manager.

Solution For Two-Stroke Engine Lubrication

BP Marine has delivered an innovative for improved cost-effective two-stroke engine lubrication. Specifically developed to offer cost effective operation while maintaining the highest levels of performance, the two-stroke engine solutions consists of two recently improved lubricants: improved Energol CLO 50M 70 BN cylinder lubricants and Energol OE-HT 30 system oil.Improved CLO 50M is claimed to reduce cost of operation through reduced wear and cleaner operation, leading to major benefits including higher margin of safety for low oil feed-rate operation, extended time between overhauls and enhanced control against scuffing. It represents…

Propulsion: Optimizing Feed Rates For Crosshead Diesels

ExxonMobil introduced a program to optimize cylinder oil feed rates in low-speed (crosshead) diesel engines. The "Feed Rate Optimization" program is designed to help minimize operating expenses by analyzing scrapedown oil as a way to detect changes in the condition of an engine¹s cylinders. The program, which is designed to help customers find a balance between the cost of cylinder oil and the expense of wear-related cylinder maintenance, analyzes scrapedown oil collected from the engine’s scavenge space, a technique pioneered by ExxonMobil. It is designed to provide comprehensive laboratory testing and analysis of the oil sample, and offers onboard testing tools that enable ship’s engineers to quickly detect substantive changes in cylinder condition.

Lubmarine Extends Delivery Network to Cyprus

Marine lubricants supplier Total Lubmarine has extended its delivery network to include Cyprus. Lubmarine has signed an agreement with Navilub Limited whereby Navilub will blend and deliver throughout Cyprus the main products in Lubmarine's range of marine lubricants, including its industry-leading Talusia HR 70 cylinder oil, Atlanta Marine system oil and the Aurelia XL and Disola ranges of trunk piston-engine oils for engines running respectively on heavy fuel oil or marine distillates. Products will be available in all major Cyprus ports, including Limassol, Larnaka, Vasiliko and Dhekelia. A barge facility is available for delivering Lubmarine's main grades via the 400 dwt Knight Star.

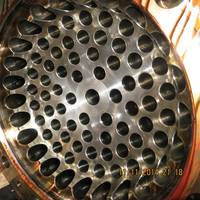

Wärtsilä Unveils New Cylinder Lubricating System

Wärtsilä Corporation has introduced a new, electronically-controlled cylinder lubricating system to meet the demand for lower cylinder oil feed rates: the Pulse Lubricating System (PLS). Developed for application in Wärtsilä RTA and RT-flex low-speed marine diesel engines, it delivers reduced cylinder oil consumption without compromising piston-running reliability. The Pulse Lubricating System makes it possible to reduce the cylinder oil feed rate compared with the existing accumulator system through an improved distribution of cylinder lubricating oil to the cylinder liner, and the fully flexible, precise timing of oil delivery.

Offshore: New Products at OTC

Sensotec's Model 424 & 425 Hammer Union pressure transmitter are rugged sensors designed specifically for use with 1502 and 2202, two-in. wing unions in the demanding environment of drilling installations. Typical high-pressure applications include mud logging, cementing, fracturing, acidizing, nitrogen pumping, and other upstream well servicing applications. The Model 425 is available in ranges from 0-5,000 to 15,000 psi. The Model 424 is available in ranges from 0-15,000 to 20,000 psi. Both the 425 and 424 deliver accuracy of 0.2% (BFSL). Standard output is 4-20 mA (2-wire) with a supply voltage of 9-28 VDC. Each unit is RFI / EMI protected. Operating temperature is from -45 to 200 degrees F. The "ESX" Power sections provide high torque at very low speed for mud motors.