AR Glasses Allow Yara Marine Technologies to Provide Remote Service

Augmented reality (AR) provides interactive access to vessel environments, like a ship’s engine room. With limited vessel access during COVID-19, Yara Marine Technologies implemented AR technology for virtual vessel access."We have been experimenting with AR glasses for some time. When the pandemic stopped our service engineers from boarding vessels, we had the alternative ready. With AR technology we have the visual field of the ship’s crew members on our monitors. While talking to the crew we can make markings, draw, and add text to the various engine parts they are looking at.

ACO Marine Unveils New PE Separators

Wastewater management specialist ACO Marine has introduced a new composite grease separator as part of its Lipator and Lipatomat product range. Manufactured from high-density polyethylene (PE) composite, ACO Marine’s new PE-Lipator (manual) and PE-Lipatomat (automatic) separators have been designed to meet market demand for more cost-effective, lighter units capable of delivering the same performance benefits as the stainless steel models, the company said. As with the stainless steel Lipator and Lipatomat units…

MHI CO2 Capture System Earns Environmental Award

A plant system that captures carbon dioxide (CO2) from flue gas emissions developed by Mitsubishi Heavy Industries, Ltd. (MHI) has received the Minister of Economy, Trade and Industry Award at the 39th Outstanding Environmental Systems Awards hosted by the Japan Society of Industrial Machinery Manufacturers (JSIM). The system was highly evaluated for its superlative reliability and economy achieved through ongoing technology improvements carried out over many years, for its abundant delivery track record in commercial applications…

MHI Awarded Concept Study of 3,400ton/day CO2 Recovery Facility

Mitsubishi Heavy Industries, Ltd. (MHI) has been awarded by Statoil, an international energy company with headquarters in Norway, to undertake a concept study for a technology qualification program (TQP) for one of the world's largest carbon dioxide (CO2) capture facilities. The approximately 3,400 tons-per-day (tpd) CO2 recovery system is targeted for installation at a 280 megawatt (MW) gas-fired combined heat and power (CHP) plant at Mongstad, on Norway's west coast. MHI will vie against other companies in a competition encompassing CO2 capture technology, facility performance, and construction and operation costs, towards facility construction slated to commence in 2016.

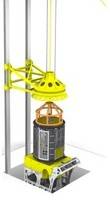

Forland Selects Kongsberg Evotec ROV System

New systems enhances ROV handling capabilities. Kongsberg Evotec, a wholly owned subsidiary of Kongsberg Maritime, has been selected to supply its sophisticated new Launch and Recovery System (E-LARS) for Remotely Operated Vehicles (ROV), for installation on a new Forland Shipping AS subsea vessel currently under construction at Havyard Leirvik, Norway. The Kongsberg Evotec’s E-LARS installation for Forland Shipping’s new 110 meters long, 22 meters wide subsea vessel, which is due for delivery in 2013, consists of both an ‘overboard’ system and a ‘moon pool’ system. The system is designed to handle work class ROVs with or without a Tether Management System (TMS) to depths below 4000m.

ROV Launch/Recovery System Chosen for Subsea Vessel

The Kongsberg Evotec's E-LARS installation for Forland Shipping's new 110 meters long, 22 meters wide subsea vessel, which is due for delivery in 2013, consists of both an 'overboard' system and a 'moon pool' system. The system is designed to handle work class ROVs with or without a Tether Management System (TMS) to depths below 4000m. Technical highlights of the new system include the use of Permanent Magnet Motor (PM) technology and an innovative control system designed…

Maxview Smart Landing System Installation

In the fourth quarter of 2008, TMEIC GE’s Maxview Smart Landing system entered service on a new ship-to-shore crane at Vancouver’s Centerm container terminal, operated by DP World (Canada) Inc. Operational data from the first 15 months proves that the semi-automatic system has met the company’s performance goals for preventing high-speed landings, which translates into reduced down-time and dollars saved. Performance results show that on average, when the Maxview Smart Landing system was in use…