Monitoring System Takes Guesswork Out of Mooring Mega Vessels

Mooring of large vessels in the LNG, petrochemical and container sectors is an intricate and critical procedure. The process entails bringing together a moving object with a static object, and with the imminent advent of even larger vessels (liquefied natural gas tankers with a capacity of 200,000 cubic meters and container ships with a capacity of 22,000 TEU*), the forces involved are enormous.

For tankers and bulk carriers, mooring frequently takes place alongside jetties at the end of finger piers, and even a gentle impact from a ship displacing more than 100,000 tons can have serious consequences. In the case of container ships docking at riverside wharves, excessive speed is likely to damage the ship more than the wharf. Even when safely berthed, fore and aft movement caused by incorrect tensioning of mooring lines can cause damage to fenders.

Fenders are primarily designed to withstand the onshore motion of a ship against jetties, wharfs and quaysides by minimizing impact damage and withstanding parallel ship movements. Any incident that causes unplanned downtime or safety issues has obvious economic implications, and it has become increasingly important to be able to determine liability for damage in the event of an incident – ship owners and leasers or port authorities and dock owners.

Trelleborg has developed a unique technological solution to the challenges of unscheduled downtime in port and data collection for insurance purposes. Called the Marine Fender Load Monitoring System (LMS), it’s designed to monitor and improve docking and berthing dynamics. The system draws on the unprecedented progress in recent decades in electronics, computers and software, and combines this technology with Trelleborg’s design and manufacture of advanced marine fender systems.

The purpose of the system is to reduce costs by increasing efficiency at ports, enhancing safety for crew and dockside personnel, optimizing mooring operations and protecting port owners’ assets. Two types of technology are used: load cell and laser based. Both systems measure impact against fenders as well as the continuing forces of a ship bearing against them.

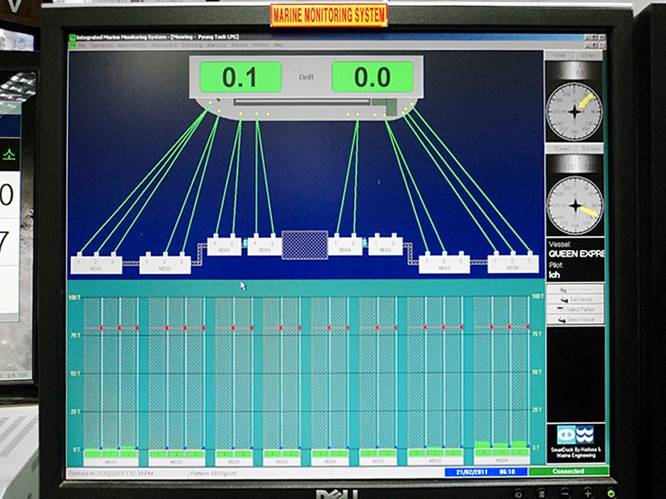

Trelleborg’s Scott Smith, Regional Director Asia Pacific for marine systems, commented, “Load cell monitoring can be located within the fender as a stand-alone installation or integrated into a common platform that also incorporates load monitoring of Quick Release Hooks, the SmartDock Laser system and the SmartDock GPS system.” A second smaller and less costly system utilizes lasers. These measure the degree of fender deflection, and the readings can be used to trigger an alarm in the event of over-compression of a fender. The third aspect of the system makes use of lasers as a docking aid system, measuring actual velocities of a vessel approaching a berth. This system can be configured as a fixed or portable installation. “The data collected via the LMS are invaluable in helping port operators plan how far they can maximize facilities without undertaking major infrastructure developments and provide them with categorical information about ships berthing outside specified parameters,” Smith said.

Advantages of the LMS system include the capability of highly accurate measurement of loads applied to wharf and docking structures and the logging of collected data over an extended period. The system can be retrofitted and engineered to suit most competitors’ fenders. As with all marine products, standards of manufacture are critical, particularly for products in use at petrochemical or LNG berths.

There is the obvious issue of electronics in the wharf “splash zone,” as well as the need to have explosion-proof enclosures. Available space for the installations can be very restricted and the loads being monitored can be in the hundreds of tons, so smart designs are essential. Crucially, the system also enables the customer to have additional insurance at the berth and a categorical evaluation as to whether a particular vessel is berthing outside specification, which can make damage and replacement a clear liability for the ship owners.

Lasers promote safe, efficient docking

The Marine Fender Load Monitoring System uses laser and load cell technology, can be fixed or portable and can be integrated with other Trelleborg products – Quick Release Hooks, the SmartDock Laser system and the SmartDock GPS system. It is designed specifically to reduce port downtime and promote safer, effective docking while providing port owners/operators with a real-time data monitoring and collection system that gives them clear indications of whether a vessel is berthing outside agreed parameters – essential in the case of damage and subsequent insurance claims.