Hepburn and Sons Joins Forces with MELD Manufacturing

Hepburn and Sons LLC announced it has officially joined forces with MELD Manufacturing Corporation, developer of the patented, solid-state metal additive manufacturing process and provider of MELD 3D printing machines. The companies have been working together since 2021 to introduce the Navy and other military services and DoD agencies to MELD, also known as additive friction stir deposition.Hepburn and Sons LLC is a small business founded in 2010 whose initial focus was to provide expert consulting…

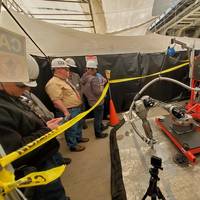

Portable Laser Shock Peening System Demonstrated for the US Navy

For the first time, a portable laser shock peening system has been developed for and demonstrated in a shipyard environment and on board a U.S. Navy warship to combat aluminum cracking.On June 24, 2022, through a 2020 National Shipbuilding Research Program (NSRP) Research Announcement Project, Hepburn and Sons LLC, teamed with LSP Technologies, Vigor Industries and the American Bureau of Shipping (ABS) was able to demonstrate for the first time ever the use of a portable Procudo LSP system both in a shipyard facility and onboard USS Cape St. George (CG-71).

Shipbuilding; NSRP Elects New Officers

The National Shipbuilding Research Program (NSRP) has announced the election of new officers to its Executive Control Board (ECB).Tom Perrine, Vice President of Engineering at Austal USA in Mobile, Ala. has been elected as ECB Chair for a two-year term, effective May 2021. Perrine earned his undergraduate degree in Naval Architecture from the University of Michigan and is a licensed professional engineer. He succeeds Don Hamadyk, Director of Program Development and Integration at Huntington Ingalls Industries’ Newport News Shipbuilding division in Newport News…

Hepburn and Sons Adds Senior Naval Talent

The Hepburn and Sons LLC team welcomed David Rice, CAPT David Bauer, USN (Ret), and Gary Loberg as their newest members. David Rice serves as Senior Consultant, Material Science. David Bauer will serve as the Senior Manager, Material Science. Gary Loberg serves as Senior Manager, Advisory Services.David Rice comes to Hepburn and Sons, LLC after a career spanning 45 years at Newport News Shipbuilding (NNS). During his time at NNS he served as the Manager of Contracted Research & Development and was responsible for Research & Development Programs funded by ONR/ManTech…

Hepburn and Sons Secures NSRP Award

The National Shipbuilding Research Program (NSRP) has awarded Hepburn and Sons LLC with the R&D Insulated Bus Pipe (IBP) Standard Interface to Naval Electrical Equipment.The team consist of Hepburn and Sons LLC, TEFELEN, NSWCPD, GD-Bath Iron Works, RSL Fiber, AeroNav, Staubli, FSU CAPS, KATO Engineering, Northrop Grumman Sykesville, General Atomics, Rolls Royce, ABS, ABB, DRS, and Roxtec. The NSRP investment is $1.14 million and the industry investment is $1.14 million. The duration of the project is 24 Months.The scope of this project is to conduct research and test a common connector that will work with the majority of electrical equipment installed on board Navy ships.

NSRP Awards Hepburn and Sons Laser Peening Work

The National Shipbuilding Research Program (NSRP) has awarded Hepburn and Sons LLC with the “Onboard Ship Integration of Laser Peening System for Lasting Aluminum Repairs.” The project team is led by Hepburn and Sons LLC and includes LSP Technologies Inc., Vigor Shipyards, ABS and NSWC Carderock Division. The NSRP investment is $1.78M and the industry investment is $1.96M. The duration of the project is 24 Months. The primary scope is to install a laser peening system onboard the Littoral Combat Ship for pre-weld and post-weld laser peening operations.Phase I will focus on the design and build of a laser peening Procudo system and a Beam Deck Delivery System and finalizing certification at NSWC Carderock Division.

NSRP Names ECB Officers

The National Shipbuilding Research Program (NSRP) has announced the election of new officers to its Executive Control Board (ECB).Don Hamadyk, Director, Research and Development at Huntington Ingalls Industries’ Newport News Shipbuilding division in Newport News, VA, has been elected as ECB chairman for a two-year term. Don earned his undergraduate and Master’s degrees from Stevens Institute of Technology.Don succeeds Tim Glinatsis, Vice President, Engineering at General Dynamics Bath Iron Works in Bath, ME.

SAFETY: Transitioning to LED Navigation Lights

The Convention on the International Regulations for Preventing Collisions at Sea (COLREGS) governs the intensity of navigation lights, requiring a minimum intensity in candelas according to a prescribed intensity formula. Changes are coming.IMO Resolution MSC.253 (83) for larger vessels sets performance standards for navigation lights, navigation light controller and associated equipment, requiring a masthead light, sidelights and a stern light installed on board a ship not less than 50 meters in length should be duplicated or be fitted with duplicate lamps…

Hamadyk Named Chair of NSRP Board

NSRP is a national collaboration of private shipbuilders that provides framework to improve shipbuilding processes. NSRP focuses on national shipbuilding and naval practices to improve the efficiency of the U.S. shipbuilding and ship repair industry.Hamadyk, who has worked for Newport News for 38 years, was instrumental in collaborating with the U.S. Navy and industry partners on the technical standards that led to the adoption of additive manufacturing of metal components for nuclear-powered warships. The first 3D part certified for use was installed on the aircraft carrier USS Harry S.

Hepburn and Sons Gets NSRP Nod Insulated Bus Pipe Support

The National Shipbuilding Research Program (NSRP) has awarded Hepburn and Sons LLC with the Qualification Testing of Insulated Bus Pipe (IBP) for Shipboard Introduction as a follow up on the Land Based Case Study of Insulated Bus Pipe (IBP) for Ship Design. Hepburn and Sons LLC leads their team members including TEFELEN, AeroNav Laboratories, General Dynamics Bath Iron Works, and RSL Fiber Systems in the project. Newport News Shipbuilding and Ingalls shipbuilding will be the supporting shipyards.

TEFELEN America Partners with Hepburn and Sons

Hepburn and Sons LLC, premier advisors to the American maritime industry, recently visited TEFELEN America in Frederick, Md. to discuss their new partnership.Hepburn and Sons LLC’s President/CEO retired U.S. Navy Captain, Rick Hepburn met with TEFELEN America’s President/CEO, Philip Brown on Thursday, June 21, 2018, to discuss conjoined marketing and sales efforts between the two companies. Also in attendance was Hepburn and Sons LLC’s Principal, Customer Relations Officer, Samantha Hepburn Hertel.In December 2017…

NSRP RA 19-01 Solicitation Issued

The National Shipbuilding Research Program issued Research Announcement 19-01 (RA 19-01) to solicit proposals for research, development and implementation of best practices in the U.S. Shipbuilding and repair enterprise. The Proposal Preparation Kit (PPK), which contains formatting guidelines, contracting requirements, proposal selection process and detailed submission instructions, has been updated to correspond with the RA 19-01 solicitation. Further details regarding RA 19-01 Solicitation can be found on the NSRP website.

Shipbuilding: $13.3 Mln Awarded for R&D Projects

The National Shipbuilding Research Program’s (NSRP) Executive Control Board has selected a new round of research and development (R&D) projects aiming to spur technology advancements in order to reduce costs associated with shipbuilding and ship repair in the U.S. The seven projects – valued at over $13.3 million, including cost share – were selected from those proposed in response to research announcement issued in July 2017, and are outlined below. Objective: The primary goal…

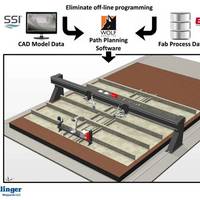

ShipConstructor Drives Automatic Welding Robots

The last barrier to robotic shipbuilding has just fallen. What comes next will be truly exciting. It wasn’t too long ago that SSI and Wolf Robotics demonstrated some co-development which automatically drove a fully autonomous welding robot to weld several ship panels. SSI develops Autodesk based solutions for the shipbuilding and offshore industry including ShipConstructor software, an AutoCAD based CAD/CAM product line; and EnterprisePlatform, a tool for sharing product data model information. For its part, Wolf Robotics has been integrating robotic welding and cutting systems since 1978. The collaboration was part of a National Shipbuilding Research Program (NSRP) Computer Aided Robotics Welding (CAR-W) project with U.S. shipyards.

Computer Aided Robotics Welding

CAD/CAM software maker SSI said it is developing solutions for Computer Aided Robotics Welding (CAR-W) consistent with its recent innovations in the area of 3D weld management. This research project is under the aegis of the U.S. Navy’s National Shipbuilding Research Program (NSRP). In December SSI representatives met with representatives from Wolf Robotics and Edison Welding Institute to advance this project. Other organizations involved include Bollinger Shipyards, Ingalls Shipbuilding, NSWCCD, Purdue University, Colorado State University, Tony Macijewski and Longview Advisors.

NSRP Selects Next Round of Shipbuilding R&D Projects

The Executive Control Board of the National Shipbuilding Research Program (NSRP) has selected a new round of research and development projects for award, as part of the program's continuing mission to reduce costs associated with U. S. shipbuilding and ship repair. These new projects, valued at over $14.5 million, including cost share, were among those proposed in response to Research Announcement 14-01, issued in June 2015. Objective: This project is a follow-on to the HiDep Weld Tfillet and Butt Weld Development RA project. It aims to implement the results of the new welding process to reduce weld distortion and improve productivity in shipyard panel construction. The new process utilizes induction heating technology and has minimal capital cost requirements.

SSI Development for Computer Aided Robotics Welding

CAD/CAM software maker SSI said it is developing solutions for Computer Aided Robotics Welding (CAR-W) consistent with its recent innovations in the area of 3D weld management. This research project is under the aegis of the U.S. Navy's National Shipbuilding Research Program (NSRP). On December 10-11, 2015, SSI representatives met with representatives from Wolf Robotics and Edison Welding Institute to further advance this development. Other organizations involved in the project include Bollinger Shipyards…

SSI CEO to Present at KORMARINE

SSI CEO Darren Larkins continues to consult with shipbuilders around the globe on how to leverage 3D Product Data Models using Autodesk technology. His next presentation on 3D Product Data Models will be October 22 at the shipbuilding and offshore show KORMARINE in Busan. Larkins will demonstrate the shortcomings of traditional methods such as using drawings, Excel files and supplementary 3D viewers, and will highlight how a better approach utilizes neutral formats and platformization. For more than 13 years Larkins has met with shipbuilders around the world, developing an understanding of industry challenges and global best practices.

NSPAD Tested, Boon for Navy

This project was originally proposed to NSRP as the Improved Advanced Watertight Door, with a goal of promoting a successful developmental door design to full commercial availability as an option to use on surface ships in place of the existing Navy Standard Watertight Door (NSWD). The NSWD, designed in the 1950s, is heavy and prone to corrosion, and possesses a complex dogging mechanism consisting of many separate parts that fall out of adjustment and suffer wear, making these doors expensive to maintain over the ship’s life cycle. The majority of NSWDs suffer loss of watertight integrity during the course of a typical deployment. The…

NSRP Awards $11m for R&D Project Portfolio

The Executive Control Board of the National Shipbuilding Research Program (NSRP) has selected a new round of research and development projects for award, as part of the program's continuing mission to reduce costs associated with U.S. shipbuilding and ship repair. These new projects, valued at over $11 million, including cost share, were among those proposed in response to Research Announcement 13-01, issued in June. Objective: The goal of this project is to transfer a cost-saving and quality-enhancing technology from the aerospace industry to the shipbuilding industry. The vision is to demonstrate the superiority of laser peening over select current shipbuilding processes in specific applications.

2015 NSRP All Panel Meeting in Charleston, SC

Registration for the All Panel Meeting of the National Shipbuilding Research Program 2015 scheduled to be held at Charleston, SC from March 10-12, 2015 is now open. The All Panel Meeting is a biennial event that brings together all eleven panels of the National Shipbuilding Research Program to: present results from recently concluded and ongoing R&D projects; discuss technology gaps in the areas of ship design, construction, and modernization; and share best practices being applied across the shipbuilding enterprise. The Registration Agenda is available on: http://www.nsrp.org/6-Presentations/apm/2015/registration_agenda.pdf To Register go to: http://surveys.scra.org/TakeSurvey.aspx?SurveyID=7lMK887 More information: http://www.nsrp.org/6-All_Panel_Meeting.html

NSPR Set to Reduce Weld Distortion

Since weld distortion is a very costly problem for U.S. shipyards, the National Shipbuidling Research Program (NSRP) has embarked on a project to reduce weld distortion through innovative Induction Heat process. A new welding process -- HiDep Arc Welding -- has been invented, which uses induction heating to heat the weld joint ahead of the arc Welding torch. By adjusting the induction heating it is possible to modify the thermal profile of the weld to prevent the asymmetrical cooling which causes most weld distortion. The process essentially substitutes induction heating instead of the arc plasma, to heat the metal being welded. The arc plasma, which occurs at the tip of the wire electrode, then is used primarily to melt the electrode.

NSRP to Host Planning, Production Processes & Facilities Panel Meeting

The National Shipbuilding Research Program (NSRP) will host the Planning, Production Processes & Facilities (PPPF) Panel Meeting November 5-6, 2014 in San Diego, Calif. The panel aims to help attendees discover and disseminate best practices related to the principal manufacturing processes, equipment, planning and facilities required to support the fabrication, assembly and testing phases of ship production. Researching and evaluating advanced technologies, tools and materials used during the ship production phase. Examining methods to optimize build strategies and improvements to facilities. Maximizing collaborative efforts with the Ship Design & Materials Panel to fully realize new technologies, tools and processes developed by both panels.