Optimizing Blast and Paint Processes in New Construction Shipbuilding

The efficacy of surface preparation and coating application in the new construction shipbuilding industry is fundamentally anchored in a well-coordinated, integrated approach. This intricate process, essential for achieving top-tier corrosion control, is methodically segmented into five crucial stages:Raw material entryPainting the modulesSmall partsPainting of erection joints at the module levelFinal paint and ship's completion. Each stage is crucial in its own right but achieves…

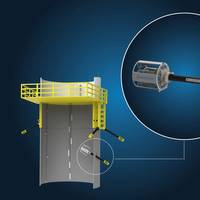

Subsea Monopile Corrosion Protection

Corrosion and BlueStream launched ICCP-SAM, touted as sustainable corrosion protection of XX(X)L monopile foundations. ICCP-SAM is designed to remotely install ICCP anodes on monopile foundations of all sizes, anywhere on the foundation and even in the roughest ocean conditions.The ICCP-SAM (Subsea Assembly Method) is compact and can be transported and deployed with minimal resources from the topside of the offshore foundation. It is operated remotely and maneuvers the anode underwater into the designated foundation entry hole. The anode is then secured to the foundation using the same tool.

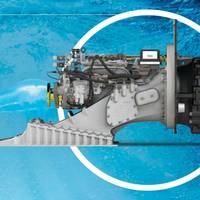

HamiltonJet Debuts New Range of Waterjets

HamiltonJet has unveiled a new range of high-efficiency waterjets, starting with the LTX36 model. Optimized for medium- and low-speed operation, New Zealand-based manufacturer said it has produced the first waterjet to rival the energy efficiency and bollard pull of the best propeller-based systems between zero and 30 knots.Waterjets are among the most efficient propulsion options for going fast due to the absence of hull-appendages and their highly optimized pump geometry, but HamiltonJet CEO Ben Reed noted not everyone wants to go fast.“Our customers’ needs are changing…

HamiltonJet Unveils HTX47 Waterjet

HamiltonJet said its new HTX47 waterjet has improved upon its previous jet model to offer a more seamless installation experience. Its new compact inboard footprint design and fully integrated hydraulics system ensures faster installation in the vessel.HTX47 new hydrodynamic design delivers 4% more high-speed efficiency, a 16% increase in peak bollard pull, and offers better operation at minimum speed, according to the manufacturer. It also features enhanced corrosion protection for more durability and expanded impeller rating range for greater compatibility for a wider range of engines.

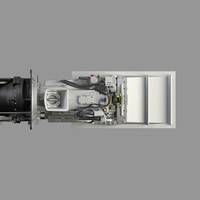

THSD Frederick Paup to Sport Schottel RudderPropellers

The largest U.S.-flagged, self propelled trailing suction hopper dredger (THSD) Frederick Paup will be propelled by a trio of Schottel RudderPropellers manufactured at the German Wismar production site. Scheduled to enter operation in 2023, the dredger will be owned and operated by Manson Construction Co., and is currently under construction at the Keppel AmFELS Shipyard in Brownsville, Texas. It will be 128 m in length, have a 25 m breadth and about 9 m draught and will have a hopper volume of 11,500 cu.

What to Keep In Mind When It Comes to HVAC

Heating, ventilation and air-conditioning (HVAC) systems keep you cool in the summer and warm in the winter. That’s the simple explanation. It does not encompass the complexities of what needs to be done to assure the all-important continued conditioning of the air in your vessel.The systems installed in vessels today can run the gamut from static vent scoops that force air into an area to a raw water chiller system whose workings take up the same amount of space as a 40-foot cargo container. The equipment is there to meet the need of the end user.

Propspeed Teams Up with Marine Protection Systems

Underwater foul-release coatings company Propspeed said it has partnered with Marine Protection Systems to educate and provide solutions to prevent corrosion and minimize damage to vessels and the marine biosphere.The insulative properties of Propspeed combined with correct anode solutions greatly improve efficiencies, reducing fuel burn and operational costs, while also minimizing the environmental impact that corrosion and coating loss has on the oceans. Propspeed and Marine…

World’s Most Famous Superyacht Gets New BWTS

The world’s most famous luxury yacht is operating an advanced BIO-SEA ballast water treatment system from France’s BIO-UV Group.Christina O, the 1943-built motor yacht named after the only daughter of Greek shipping magnate Aristotle Onassis, was fitted with a low-flow BIO-SEA system last year as part of a major refurbishment at the D.K Fotinakis yard, in Greece.To fit the limited space available in the 325ft long vessel’s machinery room, the 87m3/h capacity BIO-SEA L03-0087 system was supplied on two separate skids – one housing all mechanical components…

Marine Coatings: Propspeed Targets Commercial Sector for Growth

Propspeed launched a new kit packaged specifically for the commercial marine trade professional. Rusty Morgan, VP of Sales & Operations, Americas, discusses with Maritime Reporter TV.New Zealand-based Propspeed, a maker of underwater foul-release coatings for 21 years, recently signaled its intention to enter full-force into the commercial maritime space with the launch of its first coatings kit packaged specifically for the commercial marine trade professional. The Propspeed Commercial Kit includes all that is needed to coat two propellers 165-203cm in size…

In the Dock with Selective Electroplating

Surface plating is widely used to repair or salvage critical components in the marine industry. As many components need disassembly, the repair process is typically carried out when the ship is in dry dock. Due to the nature of the plating process, this work is usually performed by plating or machine shops off-site. In a quest to add value through reduced downtime and labor costs, many shipyards are looking to bring this service in-house. Mark Meyer, Sales Manager North America at SIFCO ASC…

Spending More Time at Sea

Margins are tight for vessels that operate offshore or in coastal waters. Take the global offshore support vessel (OSV) market for example, it looks set to be yet another challenging year which has concerned senior executives preparing for a sixth year of downturn. Many had hoped that 2019 would be the year that marked a turning point in OSV fortunes, but the uptick hasn’t materialized, and there is renewed anxiety about what could potentially be the worst market since the 1980s.It…

Total Lubmarine Launches New Engine Coolant

Marine lubricants and greases supplier Total Lubmarine has introduced its new WT SUPRA Coolant, an environmentally friendly inhibitor concentrate featuring the manufacturer's patented carboxylate technology.The new coolant, Total Lubmarine says, delivers extended service life and superior corrosion protection, providing a path to reduce operating costs, increase reliability, mitigate engine risks and reduce environmental impact.“We offer a solution to help increase operating performance and protection for both engine manufacturers and operators alike…

Subsea Robots in the Splash Zone

From their base deep within a former World War II U-boat pen, Norwegian outfit, OceanTech, is developing a set of robot tools that cling to offshore structures in order to effect inspection, maintenance and repair, or IMR. Old submarine anchorages are now subsea testing and training sites, but the North Sea is still the target. Hundreds of aging platforms and subsea structures require IMR that’s too costly, complex or hazardous for divers or remotely operated vehicles, or ROVs.As he walks us through Dora II…

Scrubber Corrosion: Addressing the Issues

A focused Q&A with M.Sc. Chem. Eng. Anders M. Sørheim, Yara Marine TechnologiesHow important is material quality when selecting a scrubber system?If the intention of a scrubber installation is to operate the scrubber for the lifetime of the vessel, assuming a minimum of 10 years, then the material quality is imperative. A study performed by the American stainless-steel manufacturer ATI titled “Evaluation of Alloys for Marine Exhaust Scrubbers – Effect of Welding and a Crevice” confirmed the importance of correct material choice for scrubbers.

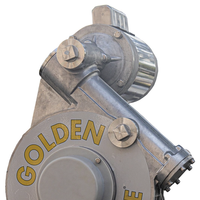

Golden Boats Lifts Enhances Sea-Drive

In over 20,000 Golden Sea-Drives manufactured, not one has ever failed. While most companies would rest on their laurels with such an impressive statistic, Golden Boat Lifts didn't. Striving to continually improve its products, it enhanced its ultra-reliable drive with more torque and even greater corrosion protection.Made in the USA, the Golden Sea-Drive still utilizes its proven double reduction worm gears so there are no chains to break or belts to slip. It's engineered so that the main gear that supports the load will never back drive…

Chevron Launches New Gear Oils

Chevron Marine Lubricants introduced a new range of gear oils designed for use in industrial and marine clutched gear systems.In developing Meropa MG gear oils, Chevron Marine Lubricants responded to customer and original equipment manufacturer (OEM) demand for gear box oils designed to ensure optimal performance in Renk and Flender/Siemens, Reintjes and Brunvoll clutched gear boxes, each extensively used in marine vessels. Meropa MG gear oils carry approvals from those gearbox manufacturers…

Austal, Fred. Olsen Partner on Trimarans

Australian-based global ship building company Austal and the UK-based, Norwegian-owned cruise shipping line Fred. Olsen have partnered on two next generation trimarans with advanced environmental credentials.Starting with the design process, Austal’s R&D team used optimized lightweight structures and the benefits of Austal’s ongoing weight reduction program to reduce the power required to achieve the vessel’s high speed.This results in significantly lower emissions from the main engines compared to a steel vessel equivalent. In addition, all-aluminum vessels do not require the same corrosion protection required in steel vessels, eliminating…

Exceptional (Market) Reach Lifts a Crane Retrofit to Success

The New York State Canal System, Advance Marine and MelCal Cranes all enjoy a reputation for versatile applications in challenging conditions. It’s no wonder that their recent deal to replace an aging maintenance crane was also a similarly good fit.When Advance Marine recently delivered a telescopic boom crane to New York State Canals, the decision regarding which type and brand of crane to select wasn’t made in a vacuum, nor was it made lightly. That’s because commercial utilization of America’s original superhighway – the Erie Canal – is on the rise again. The New York State Canal System is a 524-mile long, commercially viable waterway connecting the Hudson River with the Great Lakes, Finger Lakes, and Lake Champlain.

Jotun Signs Agreement with HHI

Norwegian paints and coatings company Jotun Group announced that it signed a memorandum of understanding with the world’s largest shipyards for a new type of marine paint that reduces solvent emissions by up to 90 percent.A memorandum of understanding has been signed with Korean Hyundai Heavy Industries (HHI). This is the starting point of a closer cooperation and the use of a new, innovative solvent-free primer.The signing took place between Jotun's chairman Odd Gleditch (Jr). and HHI's Chief Executive Ka Sam-Hyun during the South Korean President's state visit to Norway in June. South Korea's Minister of Industry Yunmo Song attended the signing ceremony."The partnership with Jotun will allow HHI…

Damen Delivers CSD500-S to ERA

Dutch shipbuilding conglomerate Damen Group announced that Damen Dredging Equipment has delivered CSD500-S, a fully customised cutter dredger for acidic environment, to Australian customer, Energy Resources of Australia (ERA)."The Cutter Suction Dredger (CSD), which has been named the Brolga I, will work in an acidic environment with a pH of approximately 3 for which a wide array of adaptations have been incorporated," it said in a press release.The dredger has been shipped to Antwerp, where it was loaded on board a transport vessel bound for the north of Australia. It will arrive at the Ranger Mine in Jabiru in the Northern Territory at the end of May.The CSD500-S is based on the Damen standard vessel type…

PPG Launches PPG AIM in U.S., Canada

PPG announced that its protective and marine coatings business (PPG-PMC) has introduced the PPG ASSET INTEGRITY MANAGEMENT (PPG AIM) system in the United States and Canada. This software-based asset management system assists facility owners, managers and maintenance engineers in scheduling, budgeting and optimizing the corrosion protection of metal structures, buildings and equipment under their care for up to 20 years in the future.The PPG AIM system is based on proprietary algorithms developed by PPG from NACE 509 and ISO 12944® corrosion-forecasting standards.

Next Generation of Corrosion Inhibiting Fuel Additives

Cortec has developed the next generation of VpCI fuel additives for more potent corrosion protection of fuel systems. Cortec VpCI-707 has been specially formulated to protect fuel tanks and systems from corrosion and sludge formation without damaging copper and aluminum. It is an option for keeping new and existing fuel tanks and systems in good condition during day-to-day operation and especially during vulnerable times such as intermittent operation, storage, or shipment. Other benefits of VpCI-707 are its improved water handling and good injector-cleaning capabilities.

Evac Acquires Transvac Systems

The cleantech solution company Evac has acquired the provider of ballast water treatment systems for ships and offshore platforms Transvac Systems.This is another important step forward for Evac who expanded their global operations by acquiring Cathelco, the UK manufacturers of equipment for ships in May 2018.Evac continue to build their reputation on the supply of integrated water and waste management systems for ships, offshore platforms and buildings worldwide resulting in sales of around 160 MEUR in the last financial year.One of Transvac’s key strengths is a long history as a supplier to the Royal Navy in the UK as well as many…